Ensuring safety in hazardous environments requires proper knowledge and preparation. The need for specialized courses that focus on handling dangerous materials, responding to emergencies, and maintaining a secure worksite is crucial. These educational programs are designed to equip employees with the skills necessary to minimize risks and comply with regulations.

By understanding key safety practices, workers can effectively navigate potential hazards and prevent accidents. Whether it’s understanding how to handle hazardous substances or responding swiftly in critical situations, having the right knowledge can make all the difference. This section provides valuable insights into the core aspects of such programs, helping you prepare for the challenges that come with working in hazardous conditions.

Learning the fundamentals of safety protocols ensures that every employee can contribute to a safer workplace. With a solid foundation, individuals can confidently manage the complexities of their environment while remaining compliant with industry standards.

Workplace Safety Knowledge for Hazardous Environments

In any high-risk job, employees must be prepared to respond to potential dangers. Specialized education programs help workers understand how to protect themselves and others from the many threats posed by toxic substances, fires, and other hazards in the workplace. Gaining knowledge in these areas is crucial for ensuring safety and complying with legal requirements.

Essential Concepts for Safe Operations

Participants in these programs learn a variety of key concepts, from recognizing environmental risks to mastering emergency response protocols. It is vital that workers know how to use personal protective equipment (PPE) and follow safe handling practices for hazardous materials. Additionally, understanding regulatory standards plays an essential role in maintaining a safe work environment.

Common Hazards and How to Address Them

Different types of hazards can affect workers, including chemical exposure, electrical risks, and physical dangers like slips, trips, and falls. Comprehensive education ensures that employees are equipped to identify, assess, and mitigate these risks effectively.

| Hazard | Safety Measures |

|---|---|

| Chemical Exposure | Proper PPE, ventilation systems, and spill containment procedures |

| Fire Risks | Fire extinguishers, evacuation plans, and emergency response drills |

| Slips, Trips, and Falls | Clear walkways, anti-slip footwear, and hazard signage |

Understanding the Importance of Workplace Safety Programs

Ensuring the safety of workers in hazardous environments is a critical responsibility. Specialized programs designed to educate employees about the risks they may face on the job help prevent accidents and reduce health risks. These programs provide essential knowledge on how to handle dangerous materials, protect oneself from potential threats, and respond effectively in emergencies.

Minimizing Risks and Preventing Accidents

Workers exposed to hazardous substances or dangerous work conditions must understand the risks involved. Proper education enables them to recognize potential threats and take steps to avoid accidents before they happen. By mastering safe practices, employees contribute to a safer work environment and ensure they are prepared for any unexpected situations.

Compliance with Legal and Regulatory Standards

Adhering to legal requirements is not only necessary for safety but also for maintaining industry compliance. Many regulations mandate that employees working in hazardous conditions undergo specific education programs to ensure they are capable of responding appropriately to risks. These regulations help safeguard workers and the environment, promoting overall safety standards across industries.

Key Components of Workplace Safety Certification

Obtaining certification in workplace safety requires a comprehensive understanding of various key elements that contribute to effective hazard management. These programs focus on equipping workers with the knowledge needed to handle dangerous situations, understand safety protocols, and ensure compliance with industry standards. There are several core components that are essential for achieving certification and ensuring a safe working environment.

Core Elements of Safety Certification

The certification process involves learning about different safety practices and procedures, which are crucial for managing risks in hazardous workplaces. Key areas of focus typically include:

- Personal Protective Equipment (PPE): Understanding how to properly use and maintain protective gear.

- Emergency Response Plans: Preparing for various emergency situations, including fire, chemical spills, and medical emergencies.

- Hazardous Material Handling: Safe methods for handling, storing, and disposing of hazardous substances.

- Regulatory Compliance: Adhering to safety regulations set by local, state, and federal authorities.

- Risk Assessment: Identifying and evaluating potential hazards in the workplace.

Training and Evaluation Process

Certification also involves a hands-on component where workers learn practical applications of safety procedures. This is typically followed by assessments or exams to evaluate their understanding and readiness to manage hazardous situations effectively. Through continuous learning and recertification, workers maintain up-to-date knowledge on the latest safety standards and techniques.

Common Safety Test Questions Explained

When preparing for safety certification exams, candidates often encounter questions that assess their understanding of essential safety protocols. These questions are designed to test knowledge about handling hazardous situations, using protective equipment, and responding appropriately to emergencies. By reviewing common test questions, workers can gain a better understanding of the topics that are most critical for ensuring safety in the workplace.

Typical Questions and Key Concepts

Commonly asked questions focus on several important areas, including:

- Personal Protective Equipment: Questions about the correct use of safety gear such as gloves, respirators, and protective suits.

- Hazardous Material Identification: Assessments on recognizing various hazardous substances and understanding their risks.

- Emergency Procedures: Questions that evaluate knowledge of evacuation protocols, fire safety, and spill response actions.

- Regulatory Standards: Understanding laws and guidelines that govern workplace safety in hazardous environments.

How to Approach Safety Exam Questions

To succeed in the exam, it is important to focus on the practical application of safety knowledge. Workers should familiarize themselves with the key concepts and best practices to confidently answer test questions. Practicing scenario-based questions can also help improve decision-making in real-life situations where safety is at stake.

How to Prepare for Safety Certification Exams

Preparing for a safety certification exam requires a focused approach, combining both theoretical knowledge and practical skills. Understanding the core topics, familiarizing yourself with common scenarios, and practicing test questions are all important steps to ensure success. By dedicating time to study and review key concepts, candidates can confidently approach the exam and demonstrate their competence in handling hazardous situations.

Essential Study Strategies

To perform well on the exam, it is important to focus on the following areas:

- Understand the Basics: Review the fundamental safety procedures, including hazard identification, risk assessment, and emergency response protocols.

- Focus on Regulations: Make sure to study the legal standards and industry regulations that govern safety practices in hazardous environments.

- Familiarize Yourself with Equipment: Know how to properly use personal protective equipment and understand its role in maintaining safety on the job.

- Practice Scenario-Based Questions: Testing your ability to make decisions in real-world situations will help build confidence and prepare you for practical application.

Effective Exam Preparation Techniques

Aside from reviewing materials, it’s also important to approach your preparation strategically:

- Set a study schedule that allows for consistent review without cramming.

- Use study guides and practice exams to assess your knowledge and identify areas for improvement.

- Join study groups or discussions to reinforce concepts and learn from others’ experiences.

By combining these strategies, candidates will be better equipped to pass their certification exams and ensure they are fully prepared for the responsibilities ahead.

Top Safety Practices for Workers in Hazardous Environments

In hazardous work environments, ensuring safety requires a set of best practices that all workers should follow. These practices help minimize risks and prevent accidents, protecting both individuals and the workplace as a whole. Understanding and implementing these safety measures is crucial for maintaining a secure and efficient work environment.

Essential Safety Measures for Workers

Here are the top safety practices that workers should adhere to when dealing with hazardous materials or conditions:

- Proper Use of Personal Protective Equipment (PPE): Always wear the appropriate protective gear, including gloves, masks, goggles, and suits, to shield yourself from harmful substances.

- Hazard Communication: Ensure clear communication regarding potential dangers in the environment, including labeling hazardous materials and following safety signage.

- Safe Handling of Hazardous Materials: Follow established protocols for handling, storing, and disposing of toxic substances to prevent exposure and spills.

- Know Emergency Procedures: Be familiar with emergency response plans, including evacuation routes, first-aid protocols, and how to use emergency equipment like fire extinguishers.

- Regular Inspections and Maintenance: Perform regular checks on equipment and the worksite to identify potential hazards and ensure everything is functioning properly.

Workplace Safety Habits for Long-Term Success

Adopting good safety habits is essential for reducing risks over time. Here are additional practices that can contribute to long-term safety:

- Stay informed about the latest safety protocols and technologies to maintain awareness of new risks and solutions.

- Participate in regular safety drills and refresher courses to reinforce best practices and remain ready for emergency situations.

- Report hazards immediately to supervisors or safety officers to prevent accidents before they occur.

By consistently following these safety practices, workers can significantly reduce the chances of injury and contribute to a safer work environment for everyone involved.

Regulatory Standards Behind Safety Programs

Compliance with safety standards is crucial for protecting workers in environments with potential hazards. Regulatory bodies establish guidelines to ensure that employees are well-prepared to handle dangerous substances and situations. These regulations are designed to safeguard not only the health and safety of individuals but also the overall well-being of the workplace and the environment.

Various government agencies, such as the Occupational Safety and Health Administration (OSHA) in the United States, play a key role in creating and enforcing safety regulations. Their standards set the framework for safe practices, training requirements, and necessary protective measures for workers exposed to hazardous materials. Adherence to these guidelines is not only a legal requirement but also a vital aspect of risk management in hazardous industries.

By following these regulatory standards, companies ensure that their employees receive the necessary education to manage risks effectively, maintain safety in the workplace, and prevent accidents or exposure to harmful substances. Regular updates to these standards help keep workers informed about new safety practices and technological advancements designed to mitigate risks.

Frequently Asked Safety Certification Questions

When preparing for a safety certification exam or program, many workers and employers have common questions regarding the process, requirements, and expectations. Understanding the most frequently asked questions can help clarify doubts and ensure that candidates are well-prepared for the certification. These inquiries often revolve around the necessary qualifications, the content of the program, and the steps to take after completing the certification.

Below are some of the most common questions related to safety certification programs:

- What are the prerequisites for certification? Many programs have specific requirements, such as previous work experience or prior safety knowledge, before certification can begin.

- How long does it take to complete the program? The duration varies depending on the complexity of the certification, with some programs taking several days or weeks to complete.

- Is there an exam after completing the program? Most certification programs require an exam to assess the knowledge gained during the course. This ensures the candidate is ready to apply safety practices in the workplace.

- How often do I need to recertify? Safety certifications typically require recertification every few years to ensure that workers remain up-to-date on current safety protocols and industry regulations.

- What happens if I fail the exam? If a candidate fails the exam, they may be given an opportunity to retake it after additional study or preparation.

Answering these questions can provide clarity and confidence to those seeking certification, allowing them to focus on the key areas of safety knowledge required for their work environment.

Role of Personal Protective Equipment in Safety Programs

Personal protective equipment (PPE) plays a critical role in safeguarding workers from potential hazards in high-risk environments. It acts as the first line of defense against exposure to toxic substances, physical injuries, and environmental dangers. By wearing the appropriate PPE, workers can significantly reduce their chances of injury or illness while performing tasks in hazardous conditions.

The use of PPE is essential for minimizing risks and ensuring compliance with safety regulations. Various types of equipment are designed for specific hazards, and understanding which gear is necessary for each situation is vital for worker protection. Proper training in the selection, use, and maintenance of PPE is equally important to ensure its effectiveness in the field.

Common types of PPE include gloves, goggles, respirators, helmets, and protective suits, each tailored to provide protection from specific risks such as chemicals, airborne particles, or physical impacts. Proper use of PPE, along with other safety practices, helps create a safer working environment and promotes long-term health and well-being for workers in hazardous industries.

How Safety Certification Ensures Workplace Safety

Effective safety programs are essential for minimizing workplace risks and ensuring the well-being of employees. By providing workers with the necessary knowledge and skills to recognize and manage potential hazards, safety certifications help create a more secure work environment. These programs not only enhance individual safety but also promote a culture of awareness and responsibility within the workplace.

One of the key benefits of safety certification programs is the structured approach they offer for managing risks. Employees are taught how to assess hazardous situations, understand safety protocols, and use protective equipment effectively. As a result, they are better prepared to handle emergencies, minimize exposure to dangerous substances, and reduce the likelihood of accidents or injuries.

Below is a table outlining the ways in which safety programs contribute to overall workplace safety:

| Benefit | Description |

|---|---|

| Risk Awareness | Employees learn how to identify potential hazards and understand the risks associated with their tasks. |

| Proper Equipment Usage | Certification programs teach the correct use of personal protective equipment (PPE) to ensure workers are fully protected. |

| Emergency Preparedness | Workers are trained on emergency response procedures, ensuring quick and effective action in case of accidents. |

| Regulatory Compliance | Certification ensures that workers and employers are in compliance with local and national safety regulations, avoiding penalties. |

By fostering a thorough understanding of safety practices, certification programs ensure that workers are well-equipped to maintain a safe and productive environment. With proper education and preparation, the chances of accidents and injuries are significantly reduced, leading to improved overall safety in the workplace.

Common Hazards Covered in Safety Programs

In environments where workers face potential dangers, it is crucial to understand the types of hazards that can arise. A comprehensive safety program addresses a wide range of risks, providing workers with the knowledge and tools they need to avoid accidents and stay safe. These hazards can range from chemical exposures to physical dangers, all of which require proper handling and precautionary measures to ensure the safety of individuals on-site.

Below are some of the most common hazards that are typically addressed in safety programs:

Chemical Hazards

Chemical hazards pose significant risks to workers, especially when handling toxic substances. These hazards may include exposure to corrosive, flammable, or reactive chemicals that can lead to burns, respiratory issues, or even long-term health problems. It is crucial for workers to understand the proper handling, storage, and disposal methods for hazardous chemicals to minimize the risk of accidents.

Physical Hazards

Physical hazards are present in nearly every industrial environment and include risks such as slips, trips, falls, and exposure to extreme temperatures or noise levels. Protective measures like fall protection systems, insulated gear, and ear protection are essential to mitigate these risks. Proper training on recognizing and addressing physical hazards is crucial for preventing injuries in the workplace.

Safety programs not only teach workers how to identify these dangers but also equip them with the skills needed to take preventative measures, ensuring a safer work environment overall.

Understanding the 40-Hour Safety Certification Course

The 40-hour safety certification course is a comprehensive program designed to equip workers with the essential knowledge and skills needed to handle hazardous materials and dangerous work environments safely. This course covers a broad range of topics, ensuring that employees are well-prepared to identify, manage, and mitigate various risks in the workplace. The training is structured to provide both theoretical knowledge and practical skills that can be immediately applied to real-world situations.

Participants in the 40-hour course gain an in-depth understanding of various hazards, safety protocols, and emergency procedures. This preparation helps minimize risks and ensures compliance with safety regulations, fostering a safer work environment. The course is particularly relevant for workers who may be exposed to hazardous substances, toxic chemicals, or hazardous waste.

Core Topics Covered

The course includes several key modules that cover a variety of crucial safety topics. Below is a summary of the main areas covered in the 40-hour program:

| Module | Description |

|---|---|

| Hazard Recognition | Teaches workers how to identify various workplace hazards, including chemical, physical, and biological risks. |

| Personal Protective Equipment (PPE) | Instructs on the proper use, selection, and maintenance of protective equipment to ensure worker safety. |

| Emergency Response | Focuses on procedures to follow in case of accidents or exposure, including first-aid measures and evacuation plans. |

| Legal and Regulatory Compliance | Explains the key regulations governing workplace safety, including OSHA standards and environmental protection laws. |

Practical Application and Evaluation

Throughout the course, participants engage in hands-on activities that simulate real-world scenarios, ensuring they can apply what they’ve learned in actual work environments. By the end of the course, workers are assessed through exams and practical demonstrations, verifying their ability to safely handle hazardous situations. Successful completion of the program results in certification, which is essential for individuals working in industries such as construction, waste management, and chemical processing.

What to Expect During Refresher Safety Courses

Refresher safety courses are essential for workers who have already completed initial certification programs and need to stay updated on the latest safety practices and regulations. These courses are designed to reinforce previous knowledge while introducing new information about emerging hazards, technologies, and regulations. The refresher course ensures that workers maintain the skills and understanding required to stay safe in environments where hazardous materials and dangerous conditions are present.

During a refresher course, participants will review key concepts, practices, and protocols related to workplace safety, and they will also engage in practical exercises to demonstrate their competence. The goal is to ensure workers can effectively apply their skills in real-world situations while maintaining a high level of safety awareness. Below is a summary of what participants can expect during this course:

Core Topics Covered

| Topic | Description |

|---|---|

| Updated Safety Standards | Review of the latest industry regulations and standards to ensure compliance with current safety laws and guidelines. |

| Advanced Hazard Identification | Reinforcement of techniques for recognizing new or evolving hazards in the workplace and strategies for managing those risks. |

| Emergency Protocols | Review of emergency response procedures, including evacuation routes, first-aid measures, and reporting incidents. |

| Protective Equipment Review | Overview of personal protective equipment (PPE) and proper usage techniques, ensuring workers are familiar with the latest equipment options. |

Interactive Learning and Practical Exercises

Refresher courses often incorporate hands-on exercises and group discussions to ensure participants are engaged and can effectively apply what they’ve learned. These activities may include simulations, case studies, and practice drills that mirror real-life situations, helping workers refresh their skills and gain confidence in their ability to respond to emergencies. By the end of the refresher course, participants are typically assessed through quizzes or practical evaluations to confirm their understanding and readiness to return to their work environments with an updated safety mindset.

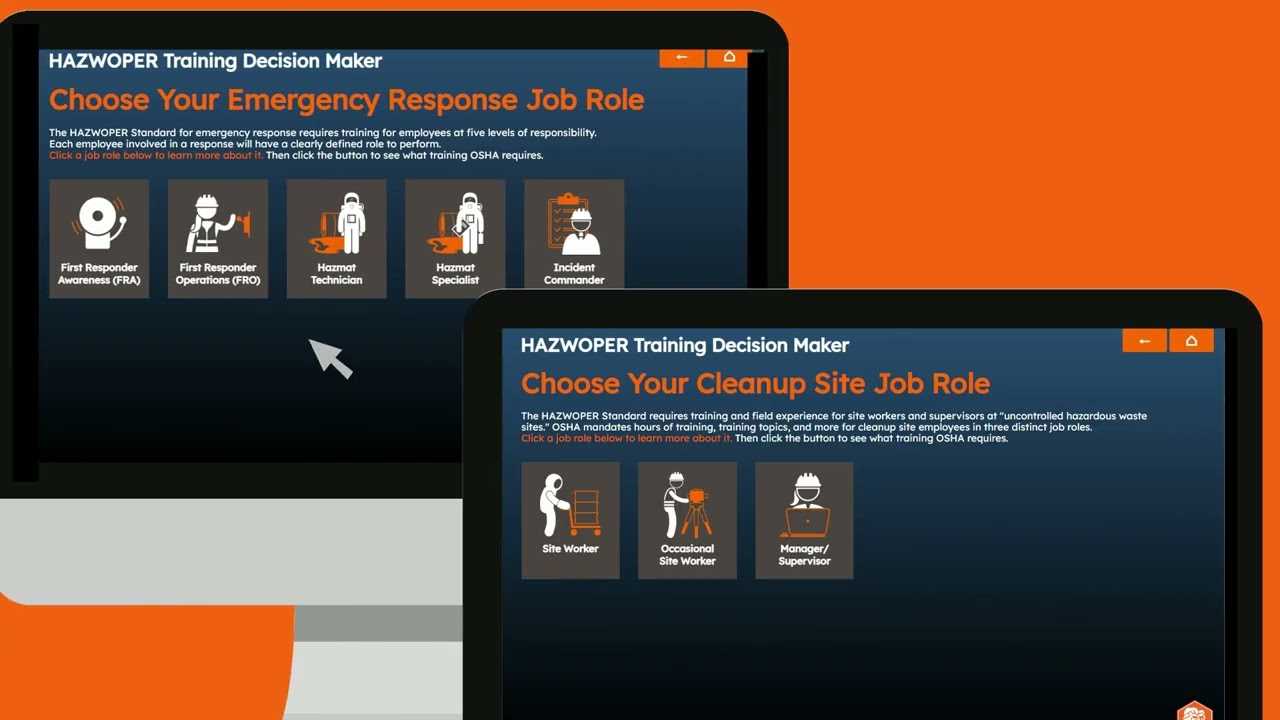

Safety Programs for Emergency Response Teams

Emergency response teams play a critical role in safeguarding both personnel and the environment in high-risk situations involving hazardous materials. These teams must be well-prepared to quickly assess and address dangerous incidents, such as chemical spills, fires, and other emergencies that could jeopardize health and safety. To ensure that responders are fully equipped to handle these challenging situations, specialized programs focus on enhancing their skills, knowledge, and ability to work safely under pressure.

These safety programs cover a broad range of essential topics designed to provide responders with the tools they need to effectively manage hazardous situations. From the proper use of personal protective equipment (PPE) to understanding the legal requirements and emergency protocols, responders receive hands-on instruction that prepares them for real-life scenarios. Below are some key components that these courses often cover:

Key Areas of Focus for Response Teams

- Incident Command System: Understanding the roles, responsibilities, and structure of an emergency response team, ensuring clear communication and effective coordination during an emergency.

- Hazardous Material Identification: Learning how to identify and assess the potential risks posed by hazardous substances in order to prioritize safety measures.

- Decontamination Procedures: Training on safe and effective decontamination processes to prevent the spread of hazardous materials and protect responders and other personnel.

- Rescue Techniques: Equipping responders with the skills to rescue individuals in distress while minimizing the risk of exposure to hazardous substances.

- Emergency Equipment Operation: Ensuring responders are familiar with the proper use and maintenance of emergency response tools and equipment, such as chemical spill kits and firefighting gear.

Practical Applications and Simulations

In addition to theoretical knowledge, these programs emphasize the importance of practical exercises and simulations. By participating in mock emergency scenarios, response teams can gain experience in making quick decisions, assessing hazards, and working together under pressure. These simulations help responders build confidence, refine their skills, and ensure that they are ready to handle real-life emergencies effectively. Moreover, ongoing practice and refresher courses are critical to keeping their skills sharp and up-to-date with the latest safety standards and regulations.

Challenges in Hazardous Material Safety Courses and Testing

Ensuring that personnel are properly prepared for handling hazardous materials involves overcoming several obstacles during both educational programs and evaluation processes. These challenges can range from ensuring the comprehension of complex safety protocols to maintaining consistent testing standards. For organizations, it is essential to address these difficulties in order to create effective learning environments that produce skilled and knowledgeable workers.

One of the primary challenges in such programs is keeping the material relevant and engaging. The content, which often involves technical safety procedures, can be dense and difficult for learners to retain. Instructors must balance providing comprehensive, in-depth information while also maintaining the attention of participants. Additionally, practical application is critical–workers need to demonstrate their skills in realistic settings, but logistical constraints, such as time and resources, can make this difficult to achieve effectively.

Another significant challenge is the assessment process. Testing often involves evaluating both theoretical knowledge and practical abilities, but accurately assessing real-world readiness can be complex. Standardized tests may fail to capture the full scope of an individual’s ability to perform in actual emergency scenarios. Furthermore, ensuring that tests are both fair and reflective of real-world conditions is essential in maintaining the credibility and usefulness of certification programs.

- Adapting to New Regulations: Keeping courses updated with evolving industry regulations and best practices can be a challenge, requiring continuous revisions to curriculum content.

- Varied Learning Styles: Learners come from diverse backgrounds and may have different learning preferences, making it difficult to design a one-size-fits-all educational approach.

- Ensuring Realistic Simulations: Practical exercises that mimic real emergency situations can be challenging to implement, especially in environments where resources and safety protocols are limited.

- Resource Constraints: Limited access to specialized equipment and training sites can hinder the ability to provide hands-on experience, which is vital for developing the necessary skills.

Ultimately, overcoming these challenges requires ongoing collaboration between educators, employers, and regulatory bodies. Continuous improvement of the curriculum, alongside innovations in teaching methods and testing standards, is crucial to ensuring that employees are fully prepared to handle hazardous situations safely and effectively.

The Benefits of Completing Hazardous Materials Safety Courses

Completing specialized safety courses for handling hazardous materials offers numerous advantages for both workers and organizations. These programs are designed to ensure that employees are well-prepared to manage dangerous substances and hazardous environments effectively. As safety regulations become stricter, having a workforce that is adequately trained becomes more important for minimizing risks and ensuring regulatory compliance.

One of the key benefits of these educational programs is the enhanced safety of workers. By gaining a deep understanding of safety protocols and emergency response procedures, employees are better equipped to prevent accidents and mitigate risks. This leads to fewer workplace injuries, lower insurance premiums, and a stronger safety culture within the organization. A well-trained workforce not only protects the individuals involved but also contributes to the overall safety of the community.

Another significant advantage is the improved compliance with industry regulations. Many sectors, particularly those that deal with hazardous materials, are governed by strict local and national laws. By completing these courses, employees demonstrate that they meet these regulatory standards, reducing the likelihood of costly fines or penalties for non-compliance. Furthermore, these programs help organizations maintain a reputation for safety, which is critical for business sustainability.

Additional benefits include:

- Increased Employee Confidence: Knowing the proper safety measures instills confidence in employees, allowing them to perform their tasks with greater focus and assurance.

- Better Emergency Preparedness: Employees are trained to respond swiftly and effectively in emergencies, improving the organization’s overall ability to manage critical situations.

- Enhanced Career Opportunities: Completing safety courses opens up more job opportunities and positions workers as knowledgeable professionals in the field of hazardous material handling.

- Stronger Organizational Reputation: Companies with a well-trained workforce are often seen as more responsible and trustworthy, leading to better business opportunities and partnerships.

Ultimately, these programs provide workers with the skills and knowledge necessary to navigate the complexities of working with hazardous materials, ensuring safer workplaces, improved compliance, and long-term career benefits for all involved.

Training for Hazardous Materials Handling

Handling hazardous materials requires a thorough understanding of safety procedures to minimize risks to health and the environment. Proper education ensures that workers are equipped with the knowledge to handle dangerous substances safely, follow regulatory guidelines, and respond to emergencies effectively. These courses focus on both the theoretical aspects of hazardous materials and the practical skills necessary for real-world applications.

One of the primary goals of these programs is to provide workers with an understanding of the various types of hazardous materials they might encounter in their work environment. It includes identifying the dangers, learning how to safely store and dispose of these materials, and understanding the proper protective equipment to use. Moreover, this type of education covers the protocols for emergency response, ensuring that workers can act quickly and efficiently in case of an incident.

Key Topics Covered in Hazardous Materials Handling Courses

The following areas are typically covered in courses designed for those handling hazardous materials:

- Identification of Hazardous Materials: Understanding the different types of chemicals, biological agents, and materials that can pose health risks or environmental hazards.

- Safety Procedures: Learning how to handle, store, and transport hazardous materials to prevent accidents and ensure proper disposal.

- Personal Protective Equipment (PPE): Identifying the correct safety gear, such as gloves, respirators, and protective clothing, necessary for working with hazardous substances.

- Emergency Response: Training in emergency protocols, including first aid, evacuation procedures, and managing spills or leaks.

- Regulatory Compliance: Understanding the legal requirements for hazardous materials handling, including OSHA and EPA guidelines, and how to comply with these standards.

Importance of Ongoing Education and Certification

While initial courses provide a strong foundation, it is essential for workers to regularly update their skills and knowledge. Refresher programs help ensure that employees stay current with new regulations, safety techniques, and equipment. Continuous education is crucial for maintaining a safe working environment and reducing the risk of incidents related to hazardous material handling.

Employers benefit from a well-educated workforce that adheres to safety standards, leading to fewer accidents, reduced legal liabilities, and improved operational efficiency. For workers, this education enhances their professional skills, making them valuable assets to their employers while ensuring their safety in hazardous environments.

How to Stay Compliant with Safety Regulations

Maintaining compliance with safety regulations is essential for any workplace that deals with hazardous materials or environments. It involves understanding the legal requirements, implementing appropriate measures, and continuously monitoring safety practices to ensure that all operations meet the necessary standards. Compliance not only prevents legal issues but also protects workers and the surrounding environment from potential harm.

To ensure ongoing compliance, companies must integrate safety protocols into their daily operations. This requires regular updates to safety plans, training sessions, and internal audits. Moreover, staying informed about regulatory changes and industry best practices is crucial for avoiding penalties and creating a safe working environment for everyone involved.

Steps to Maintain Compliance with Safety Standards

To help stay compliant, organizations can follow these essential steps:

- Regular Employee Education: Ensure that all workers are educated on safety standards and the proper procedures for handling hazardous materials. This can be done through routine safety courses and refresher programs.

- Up-to-Date Documentation: Keep all necessary safety manuals, procedures, and certifications current. Ensure that employees have access to these documents and are trained on how to follow them.

- Safety Audits: Conduct frequent audits of workplace practices and equipment to ensure they meet regulatory requirements. Identify any gaps and address them promptly to avoid compliance violations.

- Invest in Personal Protective Equipment (PPE): Provide employees with the correct protective gear and ensure that it is well-maintained and properly used at all times.

- Reporting and Record Keeping: Establish a clear system for reporting hazards and documenting all safety-related incidents. This includes maintaining logs of training sessions, equipment inspections, and any safety violations.

How to Monitor and Update Compliance

To effectively monitor and ensure compliance, companies should establish a system for continuously reviewing their safety protocols. This includes keeping track of regulatory changes, industry developments, and any updates to safety guidelines. Additionally, performing regular risk assessments helps identify potential hazards and mitigate them before they cause harm.

By staying proactive, businesses can protect both their workers and their reputation. Compliance is an ongoing process that requires attention and dedication to ensure that safety remains a top priority in every aspect of operations.