Working in environments that pose significant risks requires a deep understanding of the necessary precautions to avoid accidents. These areas demand careful attention to both potential dangers and appropriate preventive measures. Knowing how to assess risks, use equipment correctly, and follow established guidelines is crucial for ensuring that operations run smoothly and securely.

Effective management of these environments involves staying informed about the various hazards that may arise and knowing how to handle them. Workers must be equipped with the right knowledge and tools to navigate potentially dangerous situations with confidence and care. Constant training and periodic reviews play a vital role in maintaining a high level of preparedness.

In this section, we will explore the key concepts and strategies essential for operating in high-risk settings. By understanding these core principles, workers can ensure they are not only compliant with standards but also contributing to a safer and more productive workplace.

Pit Safety Overview Exam Answers

In high-risk environments, understanding the key principles that ensure a secure working space is essential. Proper training and awareness help workers identify potential threats, reduce hazards, and follow the necessary precautions to maintain a safe and efficient operation. A comprehensive approach to these areas is crucial for preventing accidents and ensuring compliance with industry standards.

Understanding critical guidelines involves more than just knowing what equipment to use or what practices to follow. It requires a deeper grasp of potential dangers, effective risk management strategies, and the protocols that govern emergency situations. Regular assessments and preparedness checks ensure that employees are always up to date on the latest safety measures and can act swiftly if needed.

Accurate knowledge of procedures is a key component in creating a safe environment. Workers must be able to recognize warning signs, respond to hazardous conditions, and apply safety measures with confidence. This section will help clarify essential concepts and practices, ensuring that all involved are equipped with the information needed to maintain a safe workspace.

Key Principles of Pit Safety

In high-risk work environments, understanding and implementing core principles is essential for preventing accidents and ensuring secure operations. These foundational practices guide workers in identifying potential hazards and responding appropriately. By adhering to well-established guidelines, individuals can maintain a structured approach to their tasks, minimizing risks and enhancing productivity.

Identifying Hazards and Risks

Recognizing potential dangers before they lead to incidents is a critical aspect of maintaining a safe environment. This involves assessing the work area regularly, understanding the nature of the tasks being performed, and anticipating possible emergencies. Awareness of these factors allows workers to take proactive measures to mitigate risks and avoid harmful situations.

Utilizing Proper Equipment and Protocols

Effective use of protective gear and following strict operational procedures are crucial elements in high-risk settings. Ensuring that all workers are equipped with the necessary tools, and are trained in their proper usage, significantly reduces the likelihood of accidents. Consistent training and adherence to these protocols are fundamental in ensuring the well-being of everyone involved.

Common Hazards in Pit Environments

Work environments that involve deep or confined spaces often present a range of dangers that can threaten the well-being of workers. Recognizing these risks is crucial to reducing accidents and maintaining a safe environment. The hazards in such settings can vary widely, but the key is being able to identify and mitigate them before they lead to serious incidents.

Structural Hazards

Unstable ground or structural failures are among the most common threats in confined spaces. Shifting soil, loose materials, or weakened walls can pose significant risks. Regular inspections, proper reinforcement, and careful planning are essential to prevent collapses or other dangerous events.

Environmental Risks

Environmental factors such as poor ventilation, toxic gases, or fluctuating temperatures can create hazardous conditions. Inadequate air circulation can lead to oxygen deficiency or the accumulation of harmful substances, while extreme temperatures can cause physical strain on workers. Monitoring air quality and ensuring proper ventilation are essential measures to minimize these risks.

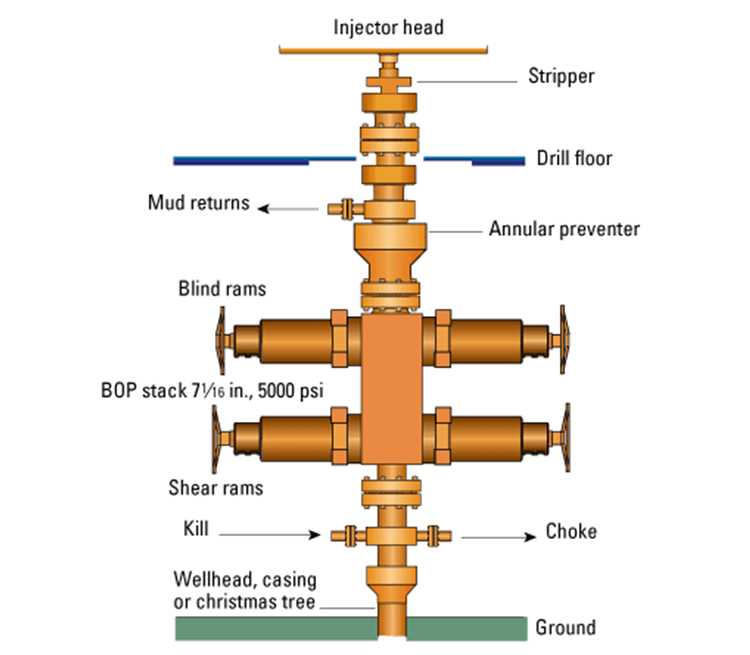

Essential Safety Equipment for Pits

In high-risk environments, the use of the right protective gear and tools is critical to preventing accidents and ensuring that workers can perform their tasks securely. Proper equipment helps mitigate the impact of potential hazards and ensures compliance with industry standards. Here is a list of essential equipment required for working in hazardous areas:

- Personal Protective Equipment (PPE): Gear such as helmets, gloves, and goggles are necessary to protect workers from physical injuries, including falling debris and sharp objects.

- Respiratory Protection: Masks and respirators are crucial when dealing with environments where airborne contaminants or a lack of oxygen might be a concern.

- Fall Protection Gear: Harnesses, ropes, and lanyards prevent falls and provide security in high or deep areas where workers may be at risk of slipping.

- Ventilation Systems: Proper airflow systems are essential to reduce the buildup of toxic gases and maintain safe air quality in confined spaces.

- Emergency Rescue Equipment: Tools such as ropes, stretchers, and rescue kits ensure that workers can be quickly assisted in the event of an emergency.

Utilizing the proper gear, along with regular checks to ensure that equipment is in good working condition, is fundamental for minimizing risks and promoting a secure working environment.

Importance of Risk Assessment in Pits

Conducting a thorough evaluation of potential hazards is crucial for ensuring the well-being of individuals working in high-risk environments. Identifying, analyzing, and addressing risks before they escalate is a fundamental part of maintaining a secure workspace. A proper assessment allows workers to take preventive measures and avoid incidents that could disrupt operations or cause harm.

Early Identification of Potential Hazards

One of the key benefits of risk evaluation is the early identification of dangers. By proactively examining the environment, workers and supervisors can spot hazards such as unstable structures, toxic fumes, or inadequate lighting. Addressing these issues before they cause problems significantly reduces the likelihood of accidents occurring.

Improved Decision-Making and Planning

Effective planning relies heavily on accurate risk assessment. Once potential threats are identified, appropriate measures can be implemented to mitigate those risks. This allows for better decision-making when it comes to assigning tasks, choosing equipment, and creating emergency protocols. Having a clear understanding of risks ensures that actions taken will be effective in promoting a safe environment.

Workplace Safety Regulations for Pits

Compliance with workplace standards is essential to ensure that risks are managed effectively in hazardous environments. Regulations are designed to safeguard workers by setting clear guidelines on how to manage potential dangers, maintain secure working conditions, and respond to emergencies. These rules apply to a wide range of procedures and equipment, ensuring that all necessary precautions are taken to minimize risk.

| Regulation | Description | Compliance Requirements |

|---|---|---|

| Risk Assessment | Evaluate the environment and identify potential hazards. | Regularly perform hazard assessments and update safety protocols. |

| Protective Equipment | Ensure workers have the necessary gear for protection. | Provide proper personal protective equipment (PPE) and ensure its use. |

| Ventilation Standards | Maintain safe air quality to prevent harmful exposure. | Install adequate ventilation systems and monitor air quality regularly. |

| Training and Certification | Ensure workers are trained in safe practices and emergency response. | Provide ongoing training and certification programs for all staff. |

By adhering to these regulations, employers create a safer environment and ensure that their workforce is equipped with the knowledge and tools necessary to handle potential hazards efficiently. Regular audits and updates to safety standards are vital to maintaining a high level of preparedness and compliance.

Personal Protective Gear for Pit Workers

Ensuring that workers are properly equipped with the right protective gear is a critical step in preventing injuries and minimizing risks in hazardous work environments. Personal protective equipment (PPE) acts as a barrier against various dangers, from physical harm to exposure to toxic substances. Proper use and maintenance of these items are essential for maintaining a secure and efficient workplace.

Essential Protective Gear

Workers in high-risk areas must wear specific gear to protect themselves from common hazards. These items include:

- Helmets: Protects the head from falling objects or accidental impacts.

- Gloves: Offers protection against cuts, burns, and exposure to hazardous materials.

- Boots: Designed to prevent foot injuries from sharp objects, heavy materials, or slippery surfaces.

- Hearing Protection: Used in environments with high noise levels to prevent hearing loss.

- Respirators: Necessary when working in areas with poor ventilation or harmful airborne substances.

Maintenance and Proper Usage

Maintaining the condition of protective equipment is just as important as wearing it. Regular inspections and prompt replacement of worn or damaged gear ensure that workers remain protected. Additionally, proper training in the use of PPE is essential to maximize its effectiveness and ensure compliance with safety standards.

Emergency Procedures in Pit Operations

In high-risk environments, having clear and effective emergency procedures in place is crucial to ensure a quick and coordinated response in the event of an incident. Proper planning and training allow workers to act swiftly, minimizing harm and ensuring that critical actions are taken to protect lives and property. Understanding these procedures is vital for all personnel involved in such operations.

Key Emergency Procedures

When an emergency occurs, it’s important to follow a set sequence of actions to ensure the safety of everyone involved. These steps may include:

- Alerting Authorities: Immediately notify supervisors or emergency services to ensure that help is on the way.

- Evacuation Protocol: Evacuate personnel from the danger zone using the designated exit routes, ensuring that everyone is accounted for.

- First Aid: Administer basic medical assistance to those injured, using appropriate first aid techniques until professional help arrives.

- Shutting Down Equipment: If possible, shut off machinery or any equipment that may be contributing to the emergency or exacerbating the situation.

Training and Preparedness

Regular training in emergency response procedures is essential to ensure that all personnel can act quickly and effectively. Workers should be familiar with evacuation routes, emergency contact numbers, and first aid procedures. Drills should be conducted periodically to reinforce these protocols and ensure that everyone knows their role in an emergency.

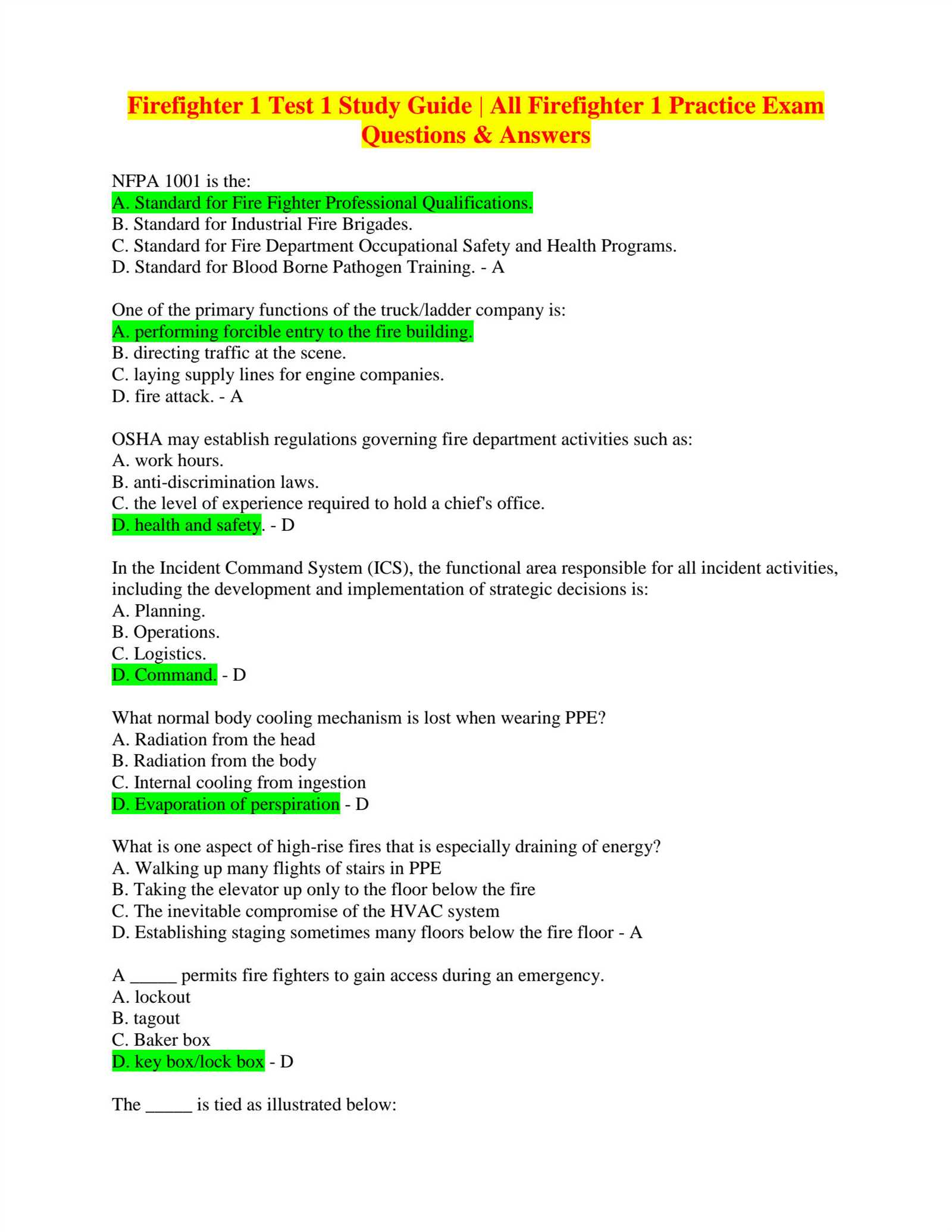

Training Requirements for Pit Safety

Ensuring that workers are well-prepared to handle potential hazards in high-risk environments is critical to maintaining a safe and productive workspace. Proper training equips employees with the knowledge and skills to recognize dangers, respond to emergencies, and follow best practices. Without adequate preparation, the risk of accidents and injuries increases significantly.

| Training Area | Description | Frequency |

|---|---|---|

| Hazard Recognition | Training on identifying and understanding common workplace hazards. | Initial training followed by annual refresher courses. |

| Emergency Response | Courses focused on handling emergencies such as fires, accidents, and evacuations. | Quarterly drills and annual certification. |

| Equipment Handling | Proper training on the operation of machinery, tools, and protective gear. | Upon hiring and as needed for new equipment. |

| First Aid and CPR | Basic medical training to provide immediate assistance in case of injuries. | Bi-annual certification updates. |

In addition to formal training, continuous education through workshops, on-the-job guidance, and safety audits helps reinforce key concepts and ensures that all employees are up to date with current procedures and regulations. Providing a comprehensive training program fosters a proactive safety culture and reduces the likelihood of incidents.

How to Identify Pit Safety Risks

Recognizing potential hazards in high-risk environments is essential for preventing accidents and ensuring the well-being of all personnel. Identifying risks involves a thorough assessment of the work area, equipment, and practices, as well as actively involving the workforce in reporting and mitigating hazards. By systematically evaluating possible threats, safety measures can be put in place before incidents occur.

Steps to Identify Risks

The process of risk identification starts with observation and analysis. Key actions include:

- Visual Inspections: Regularly walk through the work area to spot any immediate dangers, such as exposed wiring, slippery surfaces, or unguarded machinery.

- Employee Feedback: Engage workers who interact with the environment daily. They often have valuable insights into potential risks or unsafe practices that may not be immediately visible.

- Review of Incident Reports: Analyze past incidents and near-misses to determine recurring hazards or overlooked risks.

Common Types of Risks

Common threats in high-risk environments include:

- Environmental Hazards: Extreme weather conditions, poor ventilation, or inadequate lighting.

- Mechanical Hazards: Faulty equipment, unguarded machines, or improperly maintained tools.

- Human Factors: Fatigue, lack of training, or failure to follow protocols.

By using a combination of proactive measures and ongoing vigilance, the identification of potential risks can be more effective, leading to a safer and more efficient work environment.

Best Practices for Pit Inspections

Regular inspections are a critical component of maintaining a secure and efficient work environment in high-risk settings. Effective inspections allow for the early detection of potential hazards and ensure that the workplace complies with established regulations. Implementing consistent inspection practices helps minimize risks and promotes a culture of vigilance and responsibility among workers and supervisors.

Key Steps in Conducting Inspections

To conduct thorough inspections, several key steps should be followed:

- Establish a Clear Checklist: Develop a comprehensive checklist that covers all areas of concern, such as equipment functionality, environmental conditions, and worker compliance with protocols.

- Routine and Random Inspections: Schedule regular inspections, while also conducting unannounced checks to ensure that standards are consistently maintained throughout the day.

- Involve Multiple Personnel: Inspections should be conducted by trained professionals, but it is also beneficial to involve a range of staff members to provide varied perspectives on potential risks.

Documentation and Follow-Up

It is important to document findings during inspections to track issues over time and ensure accountability. Steps to take after an inspection include:

- Detailed Reporting: Record any issues identified during the inspection, along with the actions taken to resolve them.

- Immediate Corrective Action: Any hazards found should be addressed promptly to prevent accidents, with appropriate corrective measures taken.

- Review and Reassess: After corrective actions are completed, conduct follow-up inspections to verify that the issues have been properly resolved and to assess the effectiveness of the solutions.

By adhering to these best practices, organizations can ensure that inspections are not only thorough but also effective in mitigating risks and maintaining a secure work environment.

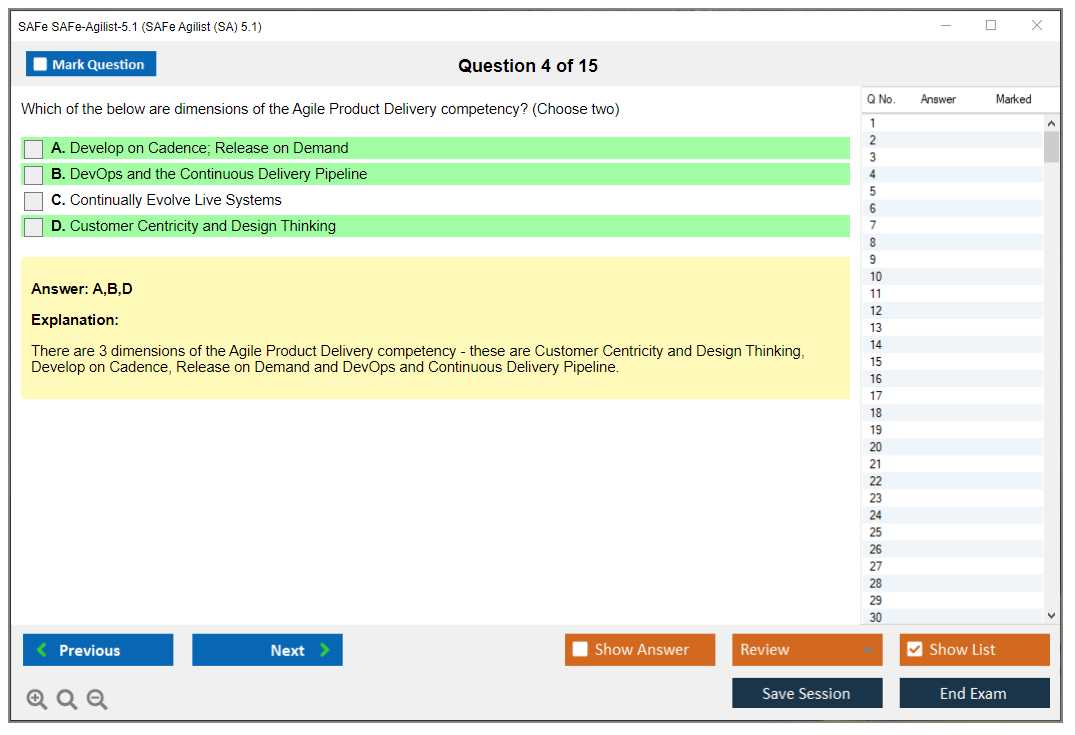

Common Mistakes in Pit Safety Exams

When assessing knowledge and preparedness in high-risk environments, individuals often make several common errors that can affect their performance. These mistakes can lead to misunderstanding key concepts or missing important details that are essential for ensuring the well-being of workers. Recognizing these frequent pitfalls helps individuals focus on areas where they need improvement, ensuring better comprehension and application of important procedures.

One common mistake is overlooking specific safety protocols. Candidates sometimes fail to recognize the significance of detailed procedures that are designed to mitigate particular risks. This can result in incorrect responses or an incomplete understanding of what is required in certain situations. Additionally, misinterpreting technical terminology is another frequent issue. Terms related to safety standards and hazard management can be confusing, and without a proper understanding, individuals may struggle to provide accurate answers.

Another common error is failing to address the human factor in hazard management. Many assessments emphasize the technical aspects, but neglecting the role of human behavior–such as training, awareness, and communication–can lead to incomplete evaluations. Lastly, ignoring the importance of regular updates is a mistake that can impact both knowledge and practice. Safety guidelines and regulations evolve over time, and staying current is crucial to making informed decisions in the field.

By being mindful of these errors, individuals can improve their performance in assessments and ultimately contribute to a safer work environment by fully understanding and applying best practices and protocols.

How to Prevent Pit-Related Accidents

Accidents in high-risk environments are often preventable with the right precautions and proactive measures. Understanding potential hazards and adopting effective strategies can significantly reduce the likelihood of incidents. By focusing on hazard identification, worker training, and the implementation of strict protocols, risks can be managed more effectively, creating a safer working environment for all involved.

Key Preventive Measures

There are several crucial steps that organizations can take to prevent accidents:

- Regular Risk Assessments: Conducting frequent assessments to identify potential hazards and taking corrective actions promptly is essential to maintaining a safe working environment.

- Proper Training and Awareness: Ensuring that all workers are properly trained in hazard recognition, emergency procedures, and equipment handling reduces the risk of human error.

- Clear Signage and Warnings: Posting visible signs and using safety barriers around dangerous areas helps keep workers aware of hazards and reinforces safety guidelines.

Importance of Personal Protective Equipment

Providing the right personal protective gear is a fundamental aspect of accident prevention. Equip workers with appropriate clothing, helmets, gloves, and footwear that are designed to shield them from specific risks. Regularly inspect and maintain these items to ensure they remain effective in preventing injuries.

By adopting these proactive strategies, organizations can significantly reduce the frequency and severity of incidents, ensuring a safer and more productive work environment.

Safety Standards for Pit Construction

Constructing deep or confined spaces requires a detailed approach to ensure both structural integrity and the well-being of workers. Adhering to specific standards and guidelines is crucial in preventing accidents and maintaining the stability of the worksite. These safety protocols outline the necessary measures to mitigate potential risks during the construction process, from planning to completion.

Key Safety Regulations

To prevent hazardous situations during the construction of underground or enclosed spaces, the following safety regulations must be observed:

- Structural Integrity: Ensuring that walls, supports, and excavation techniques are up to code is essential to preventing collapses or structural failures.

- Ventilation Systems: Adequate airflow must be maintained to avoid the buildup of dangerous gases and to provide fresh air to workers at all times.

- Fall Protection: Proper barriers, harnesses, and guardrails must be installed to protect workers from falling into deep excavations or open spaces.

Important Guidelines for Worker Protection

In addition to structural safety measures, the protection of workers should be a priority:

- Training and Awareness: Workers must be thoroughly trained in hazard identification, emergency procedures, and the proper use of personal protective equipment.

- Monitoring for Hazards: Regular inspections should be conducted to identify any emerging risks, such as unstable soil, equipment malfunctions, or hazardous conditions.

- Emergency Preparedness: Clear emergency evacuation plans and access to first aid resources are critical in the event of an accident or hazardous exposure.

By following these standards and maintaining a focus on worker health and environmental protection, the risk of accidents can be greatly reduced, ensuring the successful completion of construction projects.

Pit Safety and Environmental Considerations

When working in confined or underground areas, it is essential to prioritize both the protection of workers and the surrounding environment. These operations often involve potential risks that can impact both human health and ecological systems. Addressing environmental concerns alongside occupational hazards ensures a more holistic approach to risk management and sustainability.

Key Environmental Risks

There are several environmental challenges that arise when working in these types of spaces. These risks must be carefully monitored and mitigated:

- Soil Contamination: Excavation activities can lead to the contamination of soil with hazardous substances, potentially harming local ecosystems.

- Water Pollution: Water runoff from the site may contain harmful chemicals or sediments that could enter nearby water bodies, affecting wildlife and water quality.

- Air Quality: Confined spaces can trap harmful gases and airborne particles, which may pose a risk to workers and the surrounding area if not properly managed.

Best Practices for Environmental Protection

Implementing the following best practices helps mitigate the environmental impact of such operations:

- Proper Waste Disposal: Ensuring that waste materials, including hazardous substances, are disposed of safely and according to environmental regulations.

- Water Management: Installing effective drainage systems to control runoff and prevent contamination of nearby water sources.

- Air Ventilation: Using ventilation systems to ensure the air inside the working space remains free from harmful gases and particulate matter.

- Monitoring and Reporting: Regular environmental assessments to track potential hazards and ensure compliance with environmental standards.

By addressing both worker protection and environmental preservation, operations in confined or underground areas can proceed safely and responsibly, minimizing negative impacts on both people and nature.

Role of Supervision in Pit Safety

Effective supervision plays a crucial role in minimizing risks and ensuring the well-being of workers in potentially hazardous environments. A responsible supervisor ensures that safety protocols are adhered to, provides guidance during high-risk operations, and intervenes when unsafe practices are observed. The presence of qualified oversight is integral to maintaining order, preventing accidents, and fostering a culture of vigilance and responsibility within the team.

Key Responsibilities of Supervisors

Supervisors must be equipped with the necessary knowledge and authority to enforce safety standards and respond to emergencies. Their primary duties include:

- Training and Instruction: Ensuring all workers are properly trained and are aware of the procedures and hazards specific to the operation.

- Monitoring and Compliance: Continuously observing work conditions and worker behavior to ensure compliance with safety protocols.

- Providing Immediate Feedback: Correcting unsafe actions promptly and offering guidance on how to proceed safely.

- Incident Reporting: Documenting any safety violations or near-miss incidents to improve future operations and prevent accidents.

Impact of Effective Supervision

When supervision is robust, the risk of accidents can be significantly reduced. It promotes a proactive approach to identifying hazards and ensures that workers remain focused on maintaining a safe working environment. Moreover, it fosters teamwork and accountability, as workers know that they are being watched and guided by experienced leaders who prioritize their health and well-being.

Through diligent oversight and consistent enforcement of safety practices, supervisors help create an atmosphere where workers are more likely to follow procedures, thus reducing the chances of accidents and improving overall operational efficiency.

Evaluating Pit Safety Performance

Assessing the effectiveness of measures implemented to protect workers and maintain safe operational conditions is a crucial step in any high-risk environment. Regular evaluations provide insights into the success of current practices and highlight areas that need improvement. By systematically measuring performance, companies can ensure that they are meeting regulatory standards and continuously improving their operational safety culture.

Key Metrics for Performance Evaluation

To assess the overall effectiveness of implemented safety measures, several key metrics are typically considered:

- Incident Rate: Monitoring the frequency of accidents and near-miss events to gauge the effectiveness of safety measures and training programs.

- Compliance Audits: Regular reviews of operational procedures to ensure adherence to established standards and regulatory requirements.

- Employee Feedback: Gathering insights from workers about the safety culture, the adequacy of training, and their perception of risk in the workplace.

- Training Effectiveness: Evaluating how well workers understand safety procedures and how quickly they can react in an emergency situation.

Improving Performance Based on Evaluations

Performance evaluations not only help identify weaknesses in the system but also offer opportunities for continuous improvement. By analyzing trends and patterns from evaluation data, organizations can develop targeted interventions. These may include revising training programs, adjusting operational practices, or investing in new safety technologies. Regular evaluation ensures that the safety system evolves to meet the dynamic challenges of high-risk work environments.

In conclusion, evaluating the effectiveness of safety measures is essential for minimizing risks and ensuring that operations are carried out efficiently and safely. This ongoing process of evaluation and adjustment is key to fostering a culture of safety and preventing accidents before they occur.