When preparing for certification in gas safety, understanding the key concepts and safety protocols is crucial. This training focuses on recognizing hazardous gases and applying protective measures effectively. A solid grasp of safety standards, proper equipment usage, and emergency response procedures is necessary for ensuring both personal and workplace safety in environments with dangerous substances.

Practical knowledge is essential when facing testing scenarios. The ability to identify risks, understand emergency procedures, and handle safety equipment with precision is vital. Successful preparation involves not just theoretical understanding but also a readiness to apply this knowledge in real-world situations.

Mastering the critical topics for safety certification can make all the difference in preventing accidents and maintaining a safe work environment. With the right approach and study materials, you can ensure that you’re well-prepared for the challenges that the certification process may present.

H2S Exam Answers and Key Insights

Preparing for a certification that involves gas safety requires a deep understanding of both theoretical concepts and practical applications. This section provides valuable insights into the key topics often covered in assessments related to hazardous gas exposure and safety measures. Mastering these concepts is essential for passing the test and ensuring workplace safety in environments that may involve toxic substances.

Critical Safety Measures to Focus On

- Identification of hazardous gases and their properties

- Recognizing symptoms of exposure to dangerous gases

- Proper use of personal protective equipment (PPE)

- Understanding emergency evacuation protocols

- Testing and calibration of gas detection devices

Key Insights for Successful Certification

- Understand the difference between toxic and non-toxic gases in your environment.

- Focus on scenarios where exposure might occur and how to react effectively.

- Review the operation and maintenance of safety equipment such as gas detectors and alarms.

- Practice response strategies to ensure quick and correct actions during potential emergencies.

- Pay attention to the regulations that govern safety standards in your industry.

By focusing on these essential areas, you can improve your understanding and perform confidently when undergoing safety certification evaluations.

Understanding H2S Safety Standards

Comprehending safety protocols related to toxic gas exposure is crucial in ensuring both personal and environmental protection. These standards are designed to minimize risks by outlining specific precautions, monitoring practices, and emergency response strategies. Adhering to these guidelines is essential for anyone working in potentially hazardous areas where dangerous gases may be present.

Regulatory standards govern the levels of exposure considered safe and mandate the use of protective measures such as gas detectors, ventilation systems, and proper training. Employers are responsible for providing a safe working environment, which includes regular assessments, safety drills, and the availability of proper equipment.

Understanding these standards allows workers to identify potential hazards and take preventive actions before risks escalate. It is important to recognize the signs of gas leakage, implement safety measures, and follow the correct procedures in case of an emergency to ensure everyone’s well-being.

How to Prepare for H2S Exams

Preparation for safety certification that involves toxic gas exposure is key to successfully passing assessments. It requires not only theoretical knowledge but also practical application of safety protocols. Focused study and hands-on training can greatly improve your understanding of key concepts and increase your confidence during testing.

Focus on Core Safety Protocols

- Learn about hazardous substances and their effects on health

- Study the safety equipment and how to use it properly

- Understand emergency evacuation and rescue procedures

- Familiarize yourself with legal regulations and industry standards

Effective Study Strategies

- Review course materials and practice with sample questions

- Participate in safety drills and practical exercises

- Discuss any unclear topics with an instructor or peer

- Take regular breaks to retain information more effectively

By honing in on these areas, you will be better prepared to demonstrate your knowledge and skills, ensuring both your safety and the safety of those around you in hazardous environments.

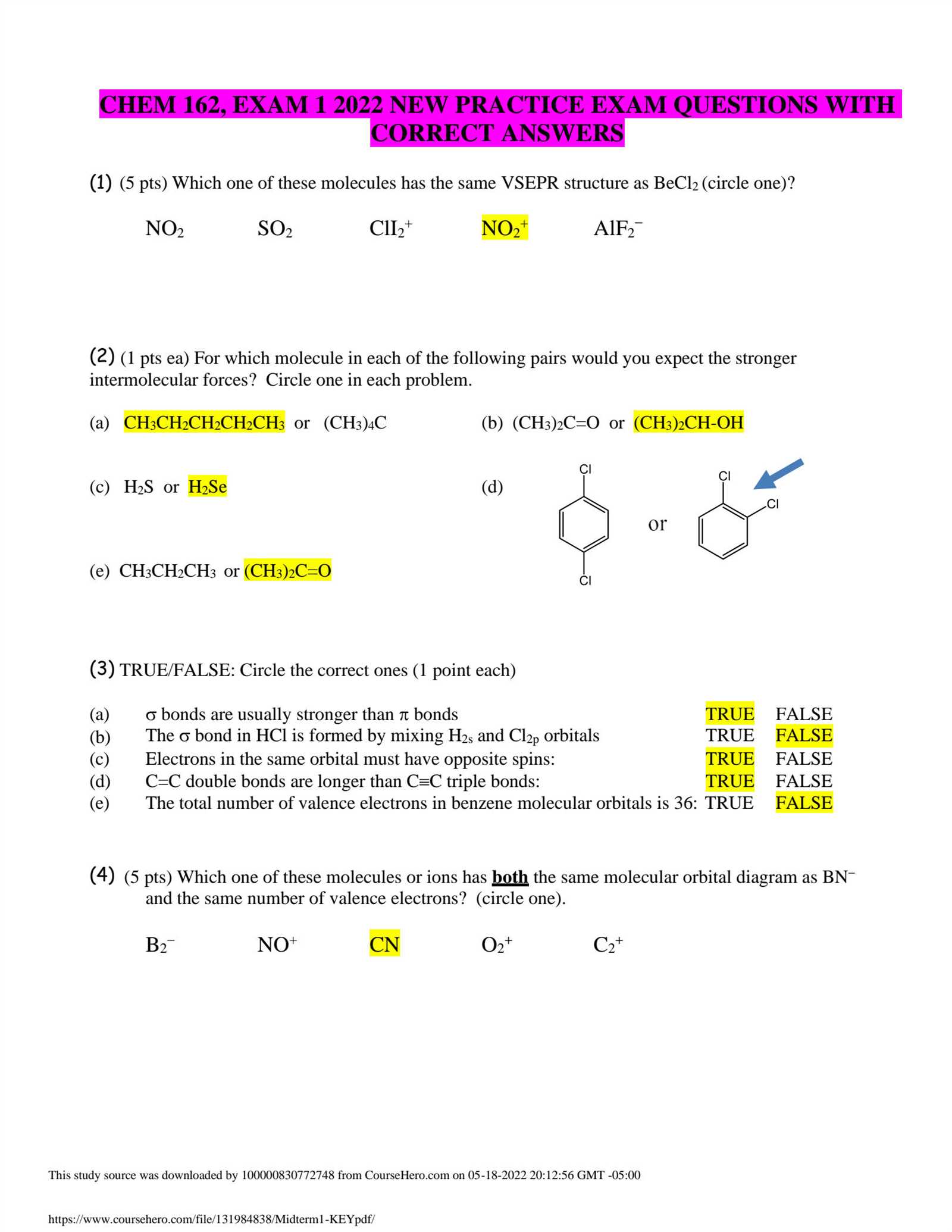

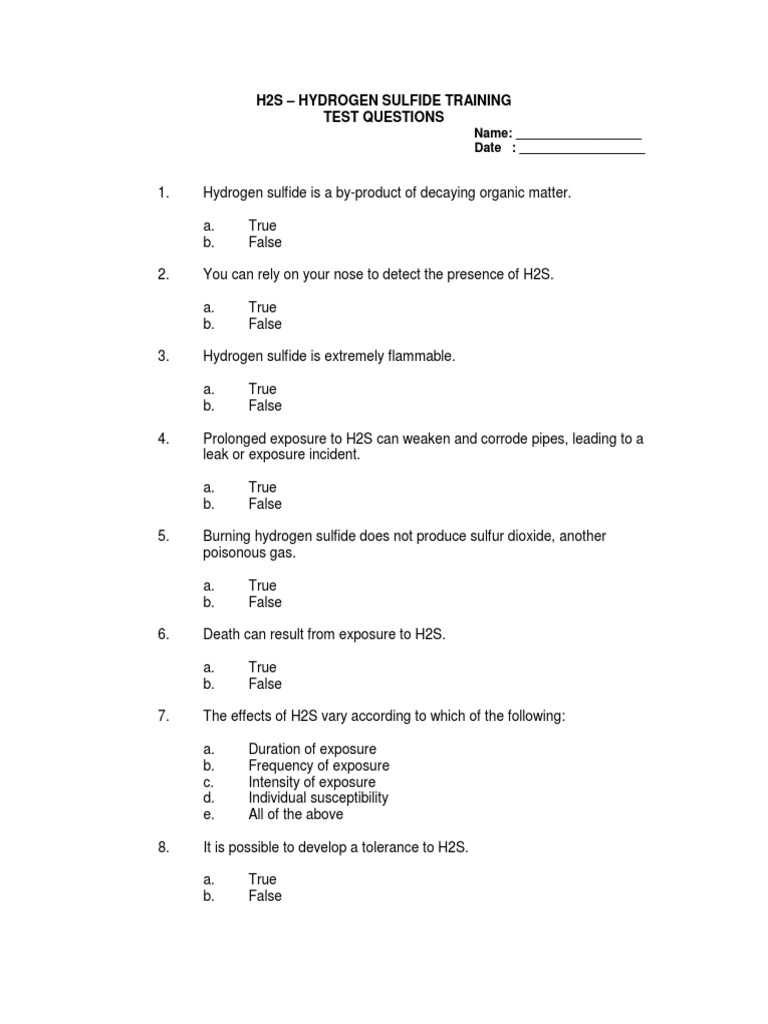

Common H2S Exam Questions Explained

Understanding the most frequently asked questions in safety assessments related to hazardous gas exposure can help you better prepare for certification. These questions typically focus on recognizing risks, knowing safety protocols, and responding effectively in emergencies. By reviewing common queries and their explanations, you can gain a clearer understanding of what is expected during the evaluation.

Key Topics Frequently Covered

- What are the symptoms of exposure to toxic gases?

- How do you properly use gas detection equipment?

- What steps should be taken during an emergency evacuation?

- How can you identify unsafe gas concentrations?

- What personal protective equipment is required in hazardous environments?

Approaching Complex Scenarios

- Describe the process of calibrating safety instruments and ensuring accuracy.

- Explain how to handle and dispose of hazardous materials safely.

- Identify the proper sequence of actions when an alarm goes off.

- What should you do if you witness an unsafe gas release?

By thoroughly understanding these common questions and their answers, you will be better equipped to demonstrate competence in real-world situations, ensuring both your safety and the safety of others around you.

Important Concepts for H2S Certification

To achieve certification in hazardous gas safety, it’s essential to grasp several core concepts that ensure both personal and environmental protection. These key principles form the foundation of your knowledge and will help you make informed decisions in risky situations. A solid understanding of these concepts is necessary not just for passing evaluations but for ensuring safety in hazardous work environments.

First, understanding the nature of toxic gases is vital. This includes knowing their physical properties, potential health effects, and how they behave in different environments. Recognizing the risks associated with gas exposure is critical in preventing accidents.

Next, proficiency in using safety equipment is another essential concept. From gas detectors to protective gear, knowing how to properly use and maintain this equipment ensures that you are well-prepared to handle dangerous situations. Being familiar with monitoring and calibration procedures is equally important for accurate readings and responses.

Finally, understanding emergency procedures, including evacuation plans and first aid measures, ensures that you are ready to act swiftly and correctly in the event of a gas leak or exposure incident.

H2S Test Tips for First-Timers

For those taking a safety certification involving toxic gas exposure for the first time, it is essential to approach the process with a focused and prepared mindset. The test typically evaluates both theoretical knowledge and practical skills, so understanding key topics and practicing safety measures is crucial. This section offers valuable tips to help you navigate the testing process with confidence.

Preparation Strategies

- Review all relevant safety protocols and guidelines thoroughly.

- Practice using safety equipment and familiarize yourself with its operation.

- Focus on understanding emergency procedures, as these may be tested in real-world scenarios.

- Take time to study any sample questions or practice tests available to familiarize yourself with the format.

Important Areas to Focus On

| Topic | Why It Matters |

|---|---|

| Gas Detection Equipment | Knowing how to use and calibrate detectors is essential for safety. |

| Emergency Response Plans | Being able to act quickly and correctly in an emergency saves lives. |

| Health Effects of Toxic Gases | Understanding symptoms and risks helps in identifying exposure early. |

| Personal Protective Equipment | Knowing what to wear and how to use PPE is critical for personal safety. |

By focusing on these key areas and practicing the relevant skills, you can significantly improve your chances of success on the safety certification. Preparation is not just about memorization; it’s about building a solid foundation of knowledge that you can apply in real-life situations.

Strategies to Improve Exam Performance

Improving your performance on a certification assessment requires a combination of effective study techniques, practical preparation, and mental focus. The goal is not only to memorize information but to understand and apply it confidently in testing scenarios. By developing the right strategies, you can approach the test with confidence and perform at your best.

Effective Study Techniques

- Active learning: Engage with the material by testing yourself regularly and practicing with sample questions.

- Focused study sessions: Break down your study time into manageable chunks and focus on one topic at a time.

- Group discussions: Collaborate with peers to discuss key concepts, which can help reinforce understanding and identify gaps in knowledge.

Maximizing Test Day Performance

- Stay calm: Keep a clear head by practicing deep breathing techniques or meditation before the test.

- Manage time: Allocate specific amounts of time to each section and avoid spending too much time on any one question.

- Read questions carefully: Ensure that you understand each question before answering and avoid rushing through the test.

Applying these strategies will not only enhance your preparation but also improve your ability to perform under pressure. By combining focused study with effective test-taking strategies, you will increase your chances of success and demonstrate a solid grasp of the safety knowledge required for certification.

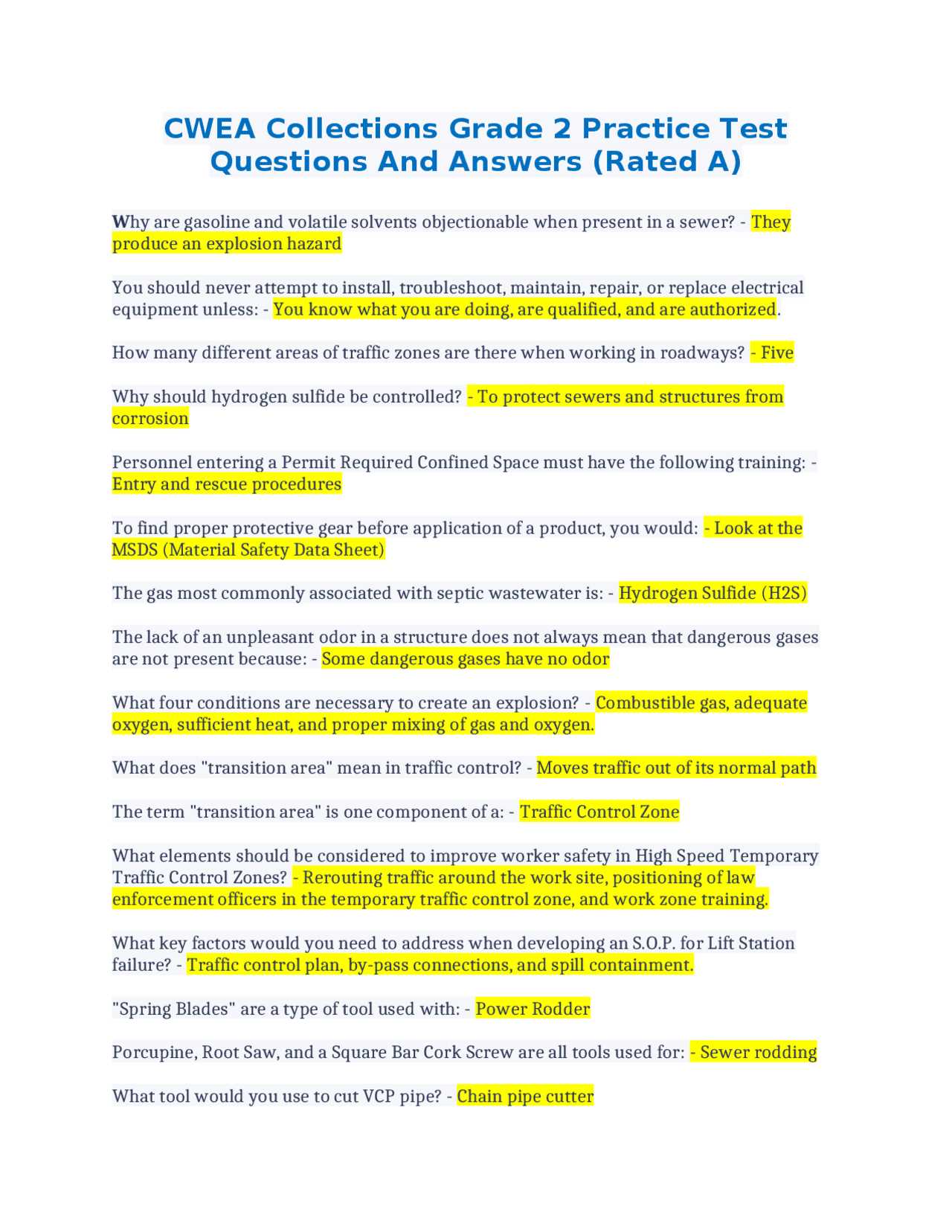

Key Safety Protocols for H2S Training

Safety training related to toxic gas exposure involves understanding and implementing specific protocols designed to minimize risks and ensure the well-being of everyone in hazardous environments. These protocols are essential in preventing accidents and injuries, providing workers with the knowledge to act quickly and effectively during potential exposure scenarios. By mastering these protocols, individuals can create a safer working environment and reduce the likelihood of exposure-related incidents.

Essential Safety Measures

- Gas Detection: Properly using gas detection equipment to monitor concentrations of hazardous gases is crucial for identifying unsafe conditions early.

- Personal Protective Equipment (PPE): Always wear the appropriate PPE, including gas masks, gloves, and suits, to protect against exposure.

- Ventilation: Ensure adequate ventilation in areas where toxic gases may accumulate to minimize the risk of inhalation.

Emergency Response Protocols

- Evacuation Procedures: Know the nearest exit routes and assembly points in case of an emergency.

- First Aid: Be prepared to administer first aid in case of exposure, including administering oxygen and seeking immediate medical attention.

- Alarm Systems: Understand how to operate and respond to alarms indicating dangerous gas levels or system malfunctions.

Familiarizing yourself with these safety protocols ensures that you are prepared for any emergency situation, minimizing risks to your health and safety while working in potentially hazardous environments.

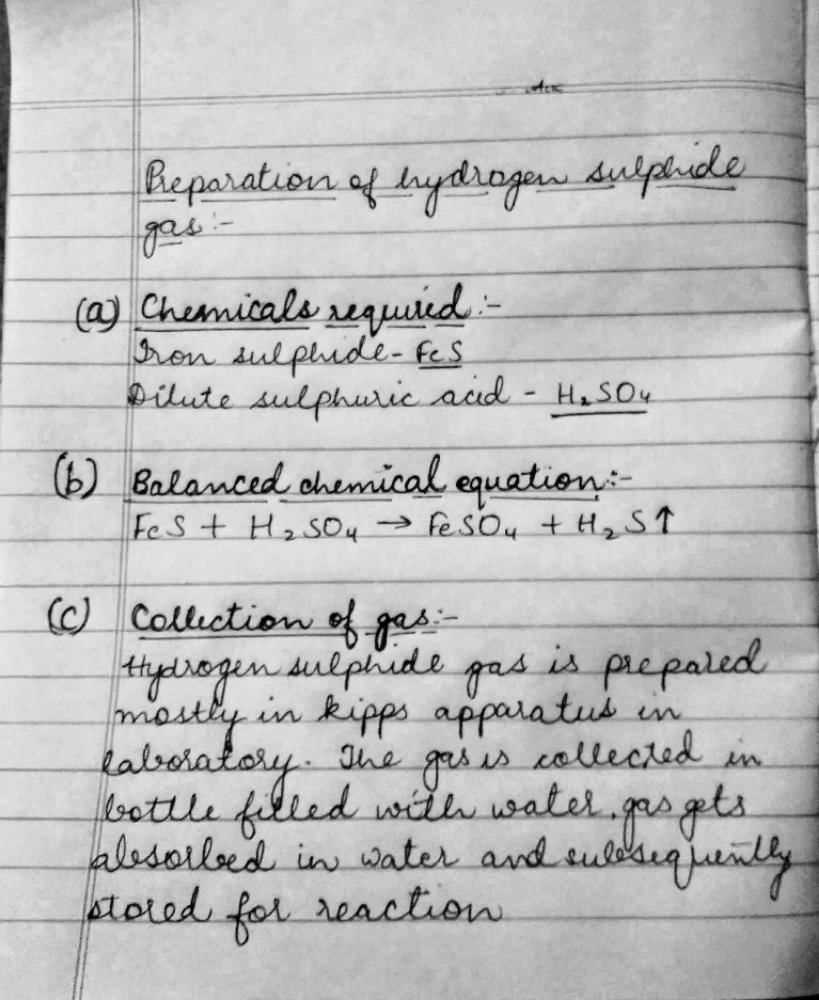

Understanding Hydrogen Sulfide Hazards

Hydrogen sulfide is a highly toxic and potentially lethal gas that can present significant risks in industrial and confined environments. Exposure to this substance can cause serious health issues and even death, depending on the concentration and duration of exposure. Recognizing the dangers associated with this gas and understanding how to mitigate these risks are critical for ensuring safety in the workplace.

Key Health Risks of Hydrogen Sulfide

- Inhalation Effects: Breathing in even low concentrations of hydrogen sulfide can irritate the eyes, nose, and throat, while higher concentrations can lead to respiratory distress or failure.

- CNS Impact: Prolonged exposure can severely affect the central nervous system, leading to dizziness, confusion, and in extreme cases, unconsciousness.

- Long-Term Health Consequences: Chronic exposure can cause neurological damage and other long-term health issues that may be irreversible.

Mitigation and Prevention Measures

- Gas Detection Systems: Continuous monitoring with reliable detection equipment is essential to identify dangerous levels of hydrogen sulfide before they reach harmful concentrations.

- Ventilation: Ensuring proper ventilation in work areas helps disperse the gas, reducing the risk of harmful exposure.

- Proper PPE: Workers should use appropriate personal protective equipment such as gas masks, respirators, and protective clothing when entering potentially hazardous zones.

By understanding the hazards associated with hydrogen sulfide and taking the necessary precautions, workers can significantly reduce the risk of exposure and ensure a safer working environment. Proper training and preparedness are vital in effectively managing these dangers.

H2S Exam Resources and Study Materials

Preparing for a safety certification that involves hazardous gas exposure requires a comprehensive understanding of key concepts, risks, and safety protocols. To effectively pass the certification process, using the right study materials and resources is essential. These tools not only help you familiarize yourself with the theoretical aspects but also provide practical scenarios to test your knowledge and readiness.

Essential Study Materials

- Official Safety Manuals: These provide in-depth knowledge about safety guidelines, risk assessments, and emergency procedures.

- Sample Questions and Practice Tests: Practicing with sample questions helps you get comfortable with the test format and identify areas that need more focus.

- Online Tutorials and Videos: Visual learning resources can be highly effective in demonstrating real-world applications of safety protocols.

Additional Helpful Resources

- Interactive Workshops: Participating in hands-on training sessions allows you to apply theoretical knowledge in controlled environments.

- Safety Guidelines and Protocols: Reviewing the most recent safety standards and industry protocols ensures that you stay up to date on current practices.

- Peer Study Groups: Collaborating with others preparing for the certification can be beneficial for sharing insights and clarifying difficult topics.

Utilizing a variety of study materials and resources is crucial for ensuring that you are fully prepared for the certification process. By combining theoretical learning with practical applications, you will be better equipped to handle the challenges that arise in real-world hazardous environments.

Top Mistakes to Avoid on H2S Exams

When preparing for safety certifications related to hazardous gases, it is crucial to avoid common pitfalls that can lead to confusion or errors during the assessment. Being aware of these mistakes allows candidates to focus on what truly matters–mastering the material and ensuring a clear understanding of the protocols involved. Avoiding these typical errors will improve your chances of successfully completing the certification process.

Common Mistakes to Watch Out For

- Rushing Through Questions: It’s important to take your time and read each question carefully. Hasty answers often result in overlooking critical details that could affect your response.

- Ignoring Safety Protocols: Not fully understanding or applying safety guidelines can lead to incorrect answers, especially in situations where protocols are emphasized.

- Neglecting Practical Knowledge: Focusing only on theoretical aspects and neglecting the practical applications of the concepts may lead to mistakes in real-world scenarios.

- Underestimating the Importance of Preparation: Skipping practice tests and review sessions can leave you unprepared for the types of questions and situations you may encounter.

How to Overcome These Pitfalls

- Stay Calm and Focused: Take deep breaths and ensure that you’re not overwhelmed by the pressure. A calm mind leads to better decision-making.

- Thoroughly Review Study Materials: Make sure to go over all relevant study materials, especially focusing on areas that you find challenging.

- Ask Questions and Clarify Doubts: If you’re unsure about a topic, seek clarification before the certification process to ensure you have a firm grasp on all necessary concepts.

By being mindful of these common mistakes and taking proactive steps to address them, you can greatly improve your chances of success during the certification process and ensure that you’re well-prepared to handle potential hazards in the workplace.

Practical Applications of H2S Knowledge

Understanding the risks associated with hazardous gases and the safety protocols that govern their handling is crucial in many industrial environments. The knowledge gained from safety training and certification is not just theoretical–it has real-world applications that can save lives and prevent accidents. By applying safety concepts effectively, workers are able to identify potential dangers, respond to emergencies, and ensure a safe working environment.

Real-World Safety Procedures

- Gas Detection: Knowing how to properly use detection equipment ensures early identification of dangerous gas concentrations, enabling swift action to mitigate risks.

- Emergency Response: Having a clear understanding of emergency protocols and evacuation procedures allows workers to act quickly and effectively in the event of a gas leak or exposure.

- Personal Protective Equipment (PPE): Applying knowledge of the correct PPE, such as respirators and protective clothing, is essential in safeguarding against exposure in high-risk areas.

Enhancing Workplace Safety

- Risk Assessment: Understanding how to assess and manage risks associated with hazardous gases helps prevent incidents before they occur, keeping both workers and the surrounding environment safe.

- Training Others: Those with solid knowledge of safety standards are in the best position to educate and train others, ensuring that the entire team is well-prepared.

- Continuous Monitoring: Knowledge of ongoing monitoring systems ensures that any changes in air quality are detected, preventing exposure to harmful substances.

The practical application of safety knowledge is a key factor in maintaining a secure working environment. By translating training into action, workers contribute to a culture of safety that benefits everyone involved.

Preparing for Written and Practical Tests

Successfully completing both theoretical and hands-on assessments for hazardous gas safety certifications requires careful preparation and a clear understanding of key concepts. The written portion typically evaluates knowledge of safety procedures, gas detection, and emergency response techniques, while the practical test focuses on applying this knowledge in real-world scenarios. Thorough preparation for both types of evaluations is essential to ensure safety and competence in potentially hazardous environments.

To excel in the written test, it is important to familiarize yourself with the material, including safety protocols, gas properties, and the use of protective equipment. Practicing with sample questions and reviewing study guides can help reinforce the theoretical knowledge necessary for the test.

The practical test, on the other hand, assesses your ability to apply the learned concepts in real-life situations. This may include demonstrating proficiency in using detection devices, responding to simulated emergency scenarios, and wearing the proper protective gear. Hands-on practice with the equipment and mock drills can help boost your confidence and readiness for the practical portion of the certification process.

By balancing both theoretical and practical preparation, you can ensure a well-rounded understanding of the safety measures and procedures required to protect yourself and others in environments where hazardous gases are present.

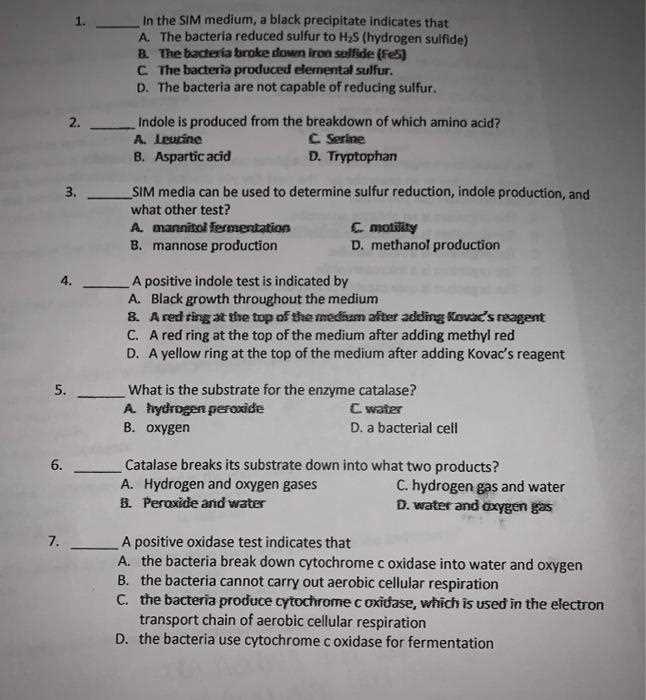

Safety Equipment and Testing Procedures

In environments where hazardous gases are present, it is essential to have the right safety equipment and to follow established testing procedures. Properly maintained equipment helps detect dangerous gases before they reach harmful levels and ensures that workers are protected. Testing procedures are equally important as they ensure that safety equipment functions correctly and is ready for use in an emergency.

Some of the most commonly used safety equipment in hazardous environments include gas detectors, personal protective equipment (PPE), and emergency escape systems. These tools are critical for maintaining a safe working environment and must be regularly tested to ensure their reliability.

Types of Safety Equipment

| Safety Equipment | Description | Testing Procedure |

|---|---|---|

| Gas Detectors | Used to detect the presence of dangerous gases in the air. | Calibrate the detector before use and check the functionality by testing with known concentrations of the target gas. |

| Respirators | Protects workers from inhaling hazardous gases or particles. | Ensure the respirator fits properly and undergoes a seal test. Regular maintenance and filter replacements are necessary. |

| Personal Protective Clothing | Clothing designed to protect against toxic or hazardous materials. | Inspect for damage or wear before use and ensure proper fit to ensure full protection. |

| Escape Breathing Devices | Used for safe evacuation in the event of a dangerous gas leak. | Check for battery life and ensure that the device is functional and easily accessible. |

Regular testing of safety equipment is crucial to ensure that it is functioning properly. Each type of equipment must be tested following established procedures, and all employees should be trained on how to use it effectively. By doing so, the safety and well-being of workers can be better assured in environments where hazardous gases are present.

Real-World Scenario Training

Practical training using real-world scenarios is crucial for preparing workers for hazardous situations they may face on the job. This type of training allows individuals to apply their knowledge in controlled, yet realistic environments, ensuring they are prepared for emergencies. It is not enough to simply understand safety protocols; hands-on experience with actual situations enhances decision-making skills and boosts confidence when facing danger.

Scenario-based training focuses on replicating dangerous conditions where workers may encounter toxic gases. Through these realistic simulations, trainees learn how to respond effectively, use safety equipment, and ensure proper evacuation procedures are followed. By experiencing and managing these situations in a safe environment, workers develop the skills needed to act swiftly and effectively under pressure.

Key Components of Scenario-Based Training

- Emergency Response Drills: Simulated situations where workers must act quickly to avoid exposure to hazardous substances. These drills help reinforce proper procedures and ensure fast, efficient responses in real-life situations.

- Use of Protective Gear: Training involves familiarizing workers with the proper use of safety equipment, such as gas masks, respirators, and personal protective clothing, to protect them from dangerous environments.

- Evacuation Procedures: Practicing emergency evacuations ensures that all personnel know the quickest and safest exit routes when exposed to toxic substances.

- Decision-Making Under Pressure: Workers are trained to make quick, informed decisions during emergencies, considering their own safety as well as that of their colleagues.

Real-world scenario training is a critical component of any comprehensive safety program. By regularly participating in these exercises, employees can build the skills, knowledge, and confidence needed to handle high-risk environments effectively. This hands-on experience ensures that workers are not only aware of potential hazards but also prepared to act decisively in dangerous situations.

Certification Renewal and Requirements

Maintaining certification for hazardous material safety is essential to ensure that workers are always up to date with the latest protocols and procedures. Renewal of such certifications involves meeting specific requirements and completing necessary training programs. These processes not only guarantee compliance with industry standards but also reinforce the importance of safety knowledge in potentially dangerous environments.

In most cases, certification must be renewed periodically, typically every few years, depending on local regulations and company policies. To remain certified, individuals are often required to undergo refresher courses, which cover updated practices and equipment usage. This ensures that workers stay prepared for any evolving risks associated with their job roles.

Key Renewal Requirements

- Completion of Refresher Training: Many industries require workers to attend a refresher course that revisits safety protocols, emergency procedures, and the use of protective equipment.

- Successful Completion of Practical Drills: Hands-on training and simulation exercises are often part of the renewal process, allowing individuals to demonstrate their ability to respond to emergencies effectively.

- Updated Knowledge of Legislation: Workers must be familiar with any changes in regulations related to hazardous material handling and safety practices in their respective industries.

- Passing a Competency Assessment: A final evaluation, typically in the form of a test or practical scenario, is often required to assess the individual’s understanding and readiness to perform safely in high-risk environments.

By keeping certifications current, individuals and organizations can ensure a safer work environment and comply with the necessary regulations. Regular renewal not only demonstrates a commitment to safety but also empowers workers with the latest tools and knowledge to handle hazardous situations confidently.

How H2S Knowledge Enhances Workplace Safety

Understanding the dangers associated with hazardous gases and their proper handling plays a crucial role in ensuring a safe work environment. Knowledge about these substances allows employees to recognize potential risks and take preventive measures to mitigate accidents. In industries where toxic gases may be present, safety awareness is vital for both individual protection and the overall safety of the team.

Proper training not only informs workers about the properties of dangerous substances but also equips them with the skills to use protective equipment effectively. This knowledge forms the foundation for responding to emergencies, ensuring that workers are prepared to act quickly and appropriately when faced with hazardous conditions.

Key Benefits of Knowledge in Workplace Safety

- Early Detection of Risks: Workers with a strong understanding of safety protocols can identify potential hazards before they escalate, reducing the likelihood of accidents.

- Effective Use of Protective Equipment: Proper training ensures that workers know how to select, use, and maintain safety gear, which can significantly reduce the risk of exposure to harmful gases.

- Improved Emergency Response: Knowledge of emergency procedures and the correct response actions can save lives, ensuring swift, decisive action during an incident.

- Compliance with Regulations: Staying informed about safety standards helps companies meet legal and regulatory requirements, avoiding penalties and maintaining a safer workplace.

How to Foster a Culture of Safety

- Regular Safety Training: Providing ongoing education and refresher courses helps employees stay current on best practices and new safety standards.

- Engagement in Safety Drills: Simulated emergency situations allow workers to practice their response strategies in a controlled environment, ensuring they are prepared for real-life scenarios.

- Encouraging Open Communication: A workplace that prioritizes safety encourages workers to speak up about potential hazards or unsafe conditions, creating a proactive safety culture.

By fostering a deep understanding of hazardous materials and safety practices, businesses can minimize the risk of accidents, protect their workforce, and create a safer environment for everyone involved.