Understanding the fundamental principles of safe practices in the food industry is crucial for anyone working in environments that involve handling or preparing consumables. Certification is often required to ensure that individuals are well-versed in these standards, which help maintain public health and prevent contamination. This section offers guidance to navigate the learning process effectively and pass the certification test with confidence.

By mastering the key concepts, candidates can demonstrate their knowledge of hygiene, safe handling techniques, and the importance of maintaining a clean and safe workspace. It’s essential to familiarize oneself with the topics typically covered in the evaluation, as they provide a solid foundation for making informed decisions in everyday tasks.

Proper preparation and a clear understanding of the relevant practices are the most effective ways to ensure success. The following content will guide you through essential areas of focus, common challenges, and practical tips for achieving certification.

Food Safety Certification Knowledge

For anyone pursuing certification in the food service industry, mastering key concepts is essential to ensure safe practices in handling and preparing consumables. Understanding the guidelines and regulations related to hygiene, temperature control, and contamination prevention is necessary to pass the evaluation and maintain a clean and safe environment for customers.

Throughout the certification process, individuals will encounter a variety of topics designed to assess their ability to make informed decisions about safety procedures. Familiarity with these areas can significantly improve the chances of success in the examination and help in performing day-to-day tasks effectively. Learning the core principles will provide the knowledge needed to adhere to industry standards and comply with health regulations.

While every examination may differ slightly, there are several universal themes that consistently appear across most tests. These topics address issues such as proper sanitation practices, safe food handling techniques, and the steps to take in preventing cross-contamination. Preparation and understanding of these key topics are vital for passing the evaluation and obtaining certification.

Understanding the Certification Process

Achieving certification in the food safety field signifies a strong understanding of critical health standards and practices. This credential demonstrates that an individual has the necessary knowledge to maintain safe environments in food-related settings. Certification programs focus on various essential concepts that help workers mitigate risks and ensure the well-being of consumers.

Importance of Obtaining Certification

Gaining this certification is not only about passing an exam; it reflects an individual’s commitment to maintaining hygiene, safety, and proper handling techniques in a professional environment. Obtaining the certification is often required by employers to meet regulatory standards, ensuring that their staff adheres to safe operational practices.

Key Topics Covered in the Certification

From basic sanitation procedures to complex safety protocols, the certification covers a wide range of subjects designed to assess readiness in real-world situations. It typically includes topics like contamination prevention, temperature control, and emergency procedures. Mastering these areas is essential to securing a successful certification outcome.

Why You Need Certification in Food Safety

Obtaining certification in food safety is essential for anyone working in environments that involve preparing, handling, or serving consumables. This credential ensures that individuals are equipped with the knowledge to adhere to health standards, preventing contamination and ensuring the safety of the public. Many regions require this certification to comply with local regulations and to protect both workers and customers from potential health risks.

In addition to meeting legal requirements, holding this certification demonstrates professionalism and a commitment to maintaining high safety standards. It reassures employers that their staff is knowledgeable about best practices, such as proper hygiene, storage techniques, and safety protocols. Employers often view certification as a key indicator of a worker’s readiness and ability to manage responsibilities effectively in food-related tasks.

Key Requirements for Certification

Achieving certification in food safety involves meeting several essential criteria that ensure individuals are fully prepared to manage safe practices in a professional environment. These requirements typically focus on both theoretical knowledge and practical skills, covering a wide range of topics related to hygiene, handling, and contamination prevention. Candidates must demonstrate proficiency in these areas to pass the assessment and receive their certification.

The following table outlines the key requirements typically needed for certification:

| Requirement | Description |

|---|---|

| Knowledge of Health Standards | Understanding the regulations and guidelines that govern safety in consumable handling and preparation. |

| Understanding Sanitation Practices | Demonstrating proper sanitation methods to prevent contamination and ensure hygiene. |

| Practical Skills in Safety Protocols | Being able to apply safety techniques in real-world scenarios, such as temperature control and cross-contamination prevention. |

| Completion of Training | Successful completion of an accredited training program to gain the necessary knowledge for certification. |

| Passing the Evaluation | Achieving a passing score on the exam that tests knowledge and understanding of safe handling practices. |

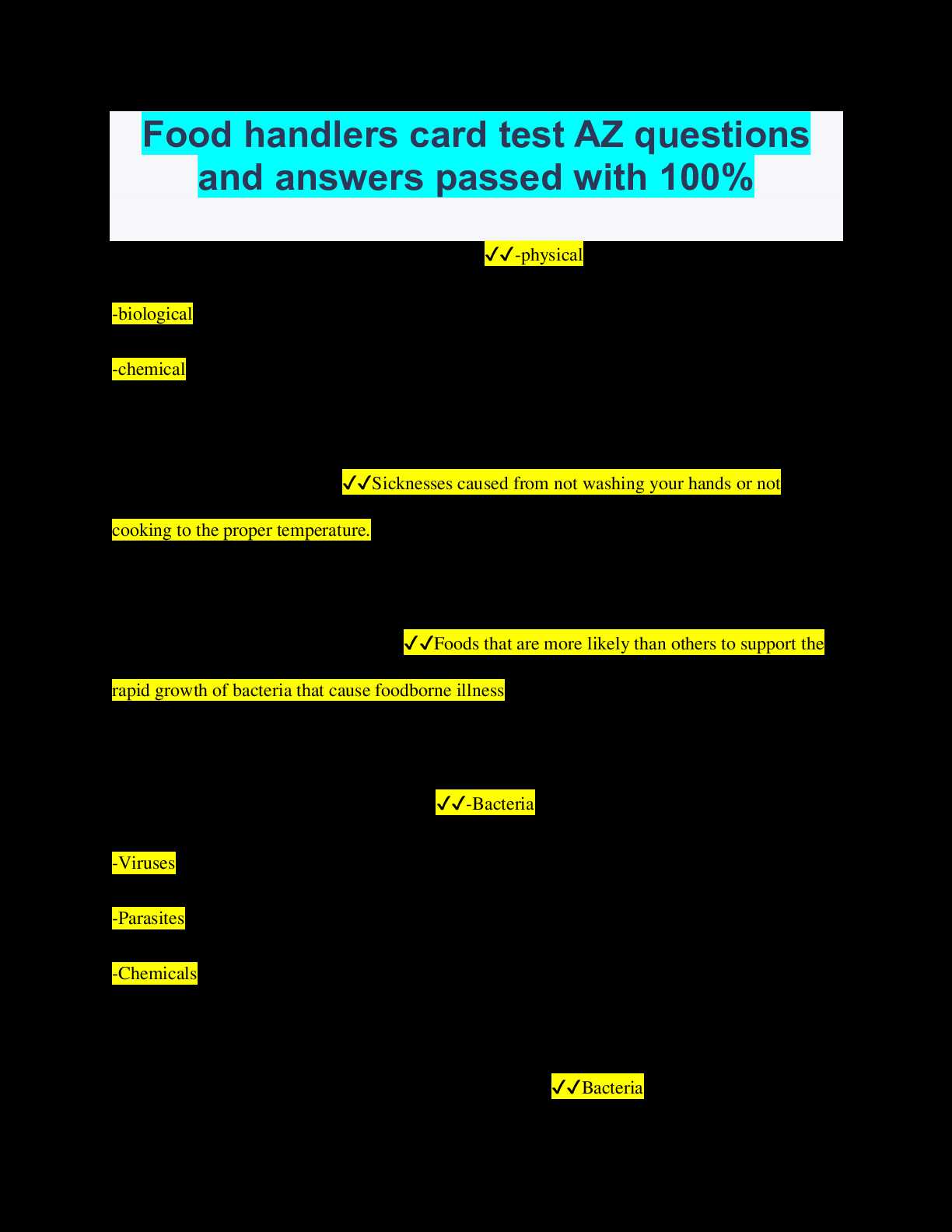

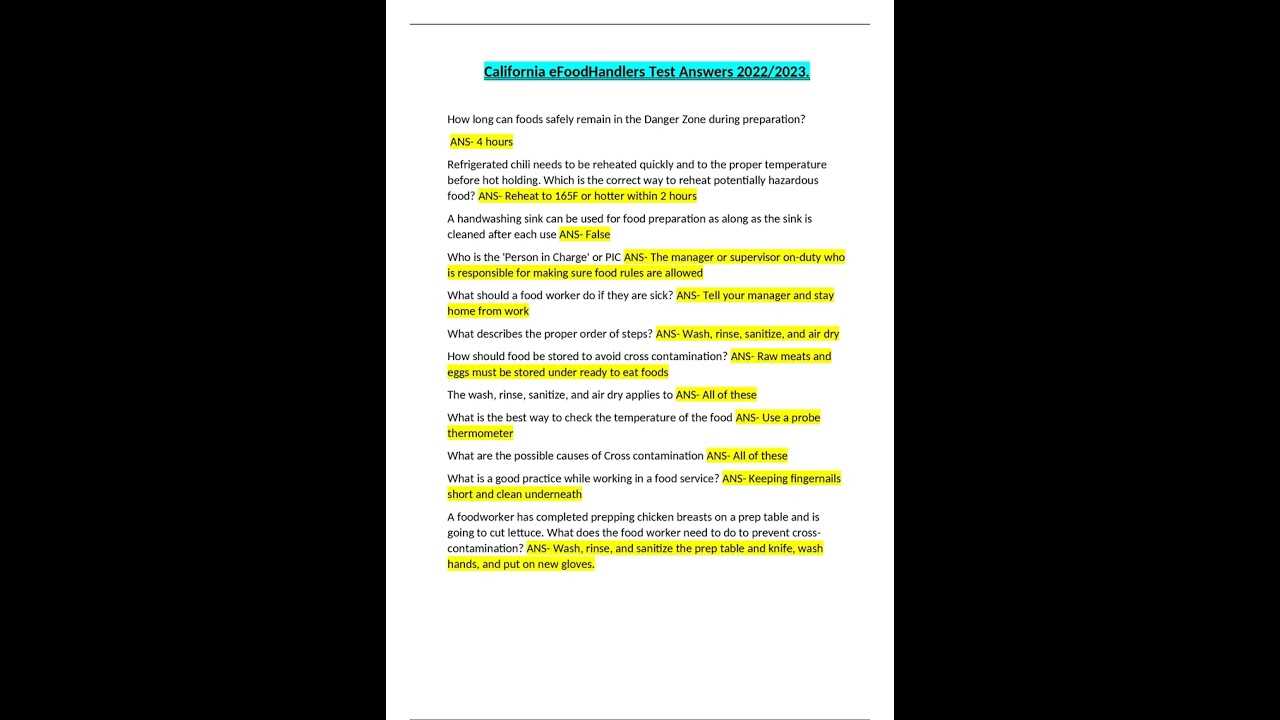

Common Questions About Safety in Food Handling

In any environment where consumables are prepared or served, it’s essential to have a clear understanding of the best practices for maintaining hygiene and preventing contamination. Many individuals have questions about the specific protocols they must follow to ensure a safe working environment. Addressing these common queries can help clarify important concepts and guide proper procedures.

Below are some frequently asked questions about maintaining safety in environments where food is handled:

- How often should surfaces be sanitized? – Surfaces should be cleaned and sanitized regularly, especially after contact with raw ingredients or utensils, to prevent cross-contamination.

- What is the safe temperature for storing perishables? – Perishable items should be stored at temperatures below 40°F (4°C) to prevent bacterial growth.

- Why is handwashing critical in a food handling setting? – Proper handwashing removes dirt and bacteria, reducing the risk of transferring harmful pathogens to consumables.

- What are the signs of foodborne illness? – Symptoms such as nausea, vomiting, diarrhea, or fever may indicate foodborne illness, requiring immediate attention and proper food handling corrections.

- When should gloves be used? – Gloves should be worn when handling ready-to-eat items or when direct contact with raw food is unavoidable.

Preparing for Your Safety Assessment

Successfully passing a safety assessment in food handling requires thorough preparation. The test is designed to evaluate your knowledge of essential practices that ensure hygiene and prevent contamination. To perform well, it’s important to focus on the key topics covered in the exam and understand the regulations that govern safe practices in food-related environments.

Key Areas to Focus On

Study the core topics, including sanitation, temperature control, cross-contamination prevention, and personal hygiene. These subjects make up the bulk of the assessment and will ensure you are ready for any questions related to safety procedures. Familiarizing yourself with these areas will give you the confidence to handle the practical application of these concepts in real-life scenarios.

Study Tips for Success

To improve your chances of success, try using practice exams to test your knowledge. Reviewing relevant materials and focusing on areas where you feel less confident will help reinforce your understanding. Consistent practice and review can make the difference between passing or needing additional preparation.

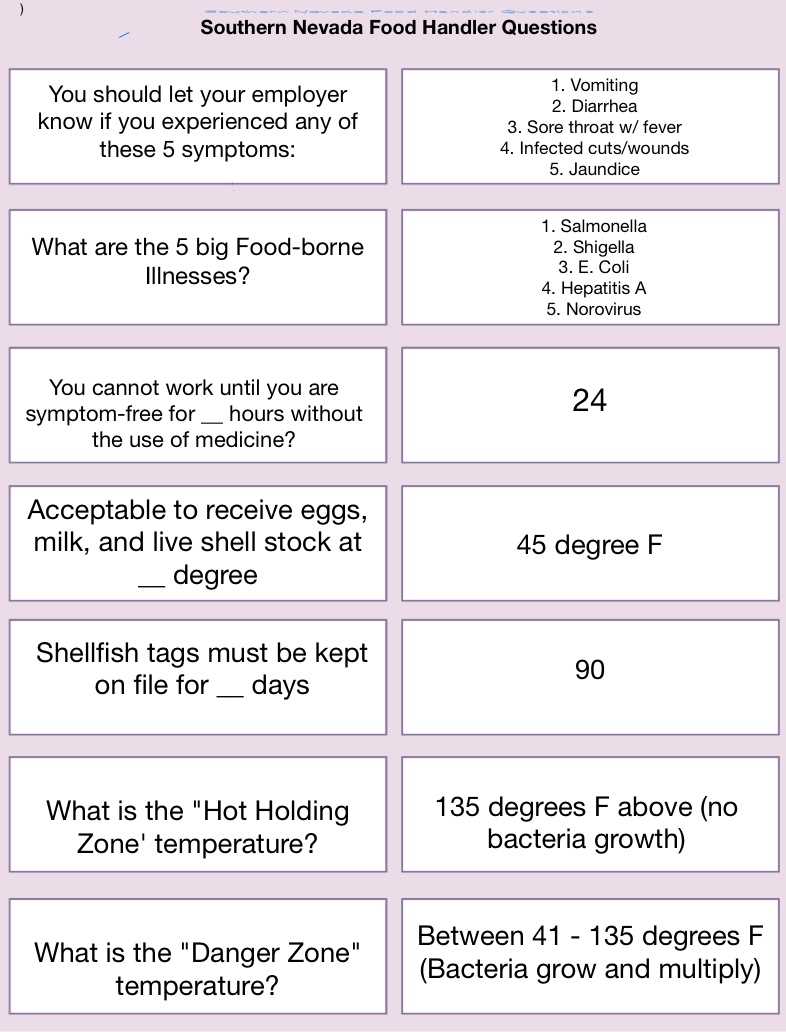

Essential Topics Covered in the Exam

The assessment designed to evaluate your knowledge of safe practices in handling consumables covers a wide range of essential topics. Understanding these subjects is critical for successfully passing the test and ensuring compliance with industry standards. The topics focus on best practices that help minimize risks and maintain a safe environment for both workers and consumers.

Key Areas to Study

- Sanitation and Cleanliness – Understanding proper cleaning techniques, including how to sanitize surfaces and utensils to prevent contamination.

- Temperature Control – Knowing safe temperature ranges for storing perishable items and reheating food to avoid bacterial growth.

- Hygiene Practices – Mastering the proper way to wash hands, wear protective gear, and handle food safely to minimize contamination.

- Cross-Contamination Prevention – Recognizing how to prevent harmful substances from transferring between raw and cooked foods.

- Allergy Management – Understanding how to handle allergens safely and communicate risks to customers effectively.

Preparation Tips for the Exam

- Study the Regulations – Familiarize yourself with local and national health codes to ensure you understand the specific rules you will be tested on.

- Review Real-World Scenarios – Think through situations where safe handling might be critical, such as handling raw meats or responding to spills.

- Take Practice Tests – Practice exams can help you get familiar with the format and question types, boosting your confidence.

Health and Hygiene Practices in the Workplace

Maintaining high standards of health and cleanliness in environments where consumables are handled is crucial for ensuring the safety and well-being of both employees and customers. Good hygiene practices prevent contamination and reduce the risk of illness. Understanding and applying these practices is vital for compliance with health regulations and creating a safe, hygienic workplace.

Key Health and Hygiene Practices

- Hand Hygiene – Regular and proper handwashing is one of the most effective ways to prevent the spread of harmful bacteria. Employees should wash their hands after handling raw materials, using the restroom, or touching potentially contaminated surfaces.

- Personal Protective Equipment (PPE) – Wearing gloves, hairnets, and aprons helps reduce the risk of contamination and maintains a clean environment. PPE should be worn according to the specific tasks being performed.

- Regular Cleaning and Sanitization – All surfaces, tools, and equipment should be cleaned and sanitized regularly. This includes countertops, cutting boards, and utensils that come into contact with consumables.

- Proper Waste Disposal – Waste should be disposed of promptly and correctly to prevent buildup that could lead to contamination. Separate bins for different types of waste, including food scraps and hazardous materials, should be used.

- Health Checks for Employees – Regular health checks can help identify and address any illnesses that may compromise hygiene and safety in the workplace. Employees showing symptoms of illness should be encouraged to stay home to prevent spreading disease.

Creating a Hygienic Work Environment

- Training and Education – Regular training on hygiene and safety protocols helps ensure that all employees understand the importance of cleanliness and are familiar with best practices.

- Maintaining Clean Restrooms – Restroom cleanliness is critical in preventing the spread of bacteria. Restrooms should be cleaned frequently and stocked with essential supplies, including soap and hand sanitizers.

- Monitoring and Enforcement – Employers should regularly monitor hygiene practices and enforce compliance to ensure that all health and safety guidelines are being followed correctly.

How to Study for the Certification

Preparing for a certification exam in safe handling practices requires a structured approach to ensure that you grasp the key concepts and procedures. Effective study not only helps you pass the test but also equips you with the knowledge to apply best practices in real-life situations. With the right focus, anyone can succeed by reviewing core topics, practicing skills, and staying disciplined in their approach.

Organize Your Study Plan

Start by breaking down the material into manageable sections. Focus on one topic at a time, such as hygiene practices, contamination prevention, or temperature control. This will allow you to master each area before moving on to the next, ensuring that your understanding is thorough and complete.

Use Practice Tests

One of the most effective ways to prepare is by taking practice exams. These tests simulate the real assessment, helping you familiarize yourself with the types of questions you may encounter. Use the results to identify areas where you need more practice, and focus your review on those topics.

Study with Others

Studying in groups or with a study partner can help reinforce key concepts. Discussing material with others can lead to new insights and a better understanding of complex topics. It also provides an opportunity to test your knowledge and learn from your peers.

Stay Consistent

Consistency is crucial when studying for any exam. Set aside dedicated time each day or week for focused study. Avoid cramming, as this can lead to unnecessary stress and poor retention of the material. A steady and consistent approach will yield the best results.

Frequently Asked Questions About Certification Cards

When it comes to certification for handling consumables safely, many individuals have questions regarding requirements, process, and validity. Understanding the common inquiries about these qualifications can help clear up confusion and guide individuals through the necessary steps to obtain and maintain their certification. Below are some frequently asked questions that address key concerns.

Common Inquiries

| Question | Answer |

|---|---|

| Who needs to get certified? | Anyone involved in handling consumables, including preparation, service, or packaging, is generally required to obtain a certification in hygiene and safety practices. |

| How long does certification last? | Typically, certifications are valid for 3-5 years, depending on local regulations and industry standards. Renewal may require re-taking an exam or completing refresher courses. |

| What is covered in the certification exam? | The exam generally covers essential safety practices, such as sanitation, temperature control, cross-contamination prevention, and proper handling techniques for consumables. |

| Can I take the exam online? | Yes, many certification programs now offer online exams for convenience. However, it is important to confirm whether the online version is accepted by local health authorities. |

| Do I need to pay for the exam? | Yes, there is typically a fee associated with taking the certification exam. The cost varies depending on the program and region. |

Importance of Safety in Restaurants

Maintaining high standards of cleanliness and safety is crucial in dining establishments, as it directly impacts the health of customers and the overall success of the business. A safe environment not only prevents the spread of harmful pathogens but also ensures compliance with regulations, fosters trust with patrons, and upholds the establishment’s reputation. In restaurants, where consumables are handled and served, proper practices are essential to minimize risks and ensure the well-being of all individuals involved.

Health and Safety Compliance

One of the primary reasons for implementing safety standards is to comply with local and national regulations. Regulatory bodies require establishments to adhere to specific safety protocols to protect the public from foodborne illnesses. Non-compliance can result in penalties, fines, or even the closure of the business. Establishing clear procedures for safe handling, preparation, and storage of products ensures that the restaurant meets legal requirements and avoids any negative consequences.

Building Customer Trust

Customers are more likely to return to a restaurant that prioritizes hygiene and safe practices. When patrons see that an establishment follows proper sanitation procedures, it builds trust and confidence in the quality of the meals being served. In turn, this can lead to positive reviews, repeat visits, and a strong customer base, all of which contribute to the long-term success of the restaurant.

What to Expect During the Exam

Taking the certification exam for safe handling practices can seem daunting, but knowing what to expect can help you prepare and approach it with confidence. The test typically evaluates your knowledge of hygiene, safety protocols, and how to properly manage consumables in a professional environment. Understanding the structure of the exam and the types of questions you may encounter will allow you to focus your preparation effectively and reduce any stress.

Exam Structure

The exam usually consists of multiple-choice questions designed to assess your understanding of key safety concepts. These questions may cover topics such as contamination prevention, temperature management, cleaning procedures, and legal requirements. Here’s what you can expect:

- Duration: Most exams last between 60 to 90 minutes.

- Question Types: Multiple-choice and true/false questions are common.

- Passing Score: A passing score is typically around 70%, but this can vary by location.

Topics Covered

The following areas are commonly tested during the exam:

- Proper hygiene and sanitation techniques

- Safe handling and storage of consumables

- Prevention of cross-contamination

- Temperature control and monitoring

- Understanding of foodborne illnesses and their prevention

Being well-prepared in these areas will help you succeed in the exam and equip you with the skills needed for a safe and efficient workplace.

Certification Renewal Process

After obtaining your initial qualification, it is important to stay up-to-date with the latest safety protocols and industry standards. The renewal process ensures that your knowledge remains current and that you continue to meet the necessary regulations for working in environments where consumables are handled. In this section, we will outline the steps involved in renewing your certification and the key requirements you need to be aware of.

The renewal process is typically straightforward but can vary depending on your location and the certifying body. Most jurisdictions require professionals to renew their certification every 3 to 5 years. The process often involves taking a refresher course, submitting proof of continuing education, or retaking the exam to demonstrate that you are still knowledgeable about safe practices.

To ensure a smooth renewal, it is important to track the expiration date of your certification and allow enough time to complete the necessary steps. Renewing on time will prevent any lapses in your certification status, ensuring that you remain compliant with health and safety regulations at all times.

Common Mistakes to Avoid During the Test

Taking a certification exam can be challenging, especially when it comes to ensuring that you avoid common errors that could impact your results. Whether you’re unfamiliar with the exam format or feeling nervous, there are several mistakes that test-takers frequently make. Recognizing and addressing these potential pitfalls can help you improve your performance and ensure that you pass the test with confidence.

Common Errors to Avoid

Below are some of the most frequent mistakes individuals make during the exam:

- Rushing through questions: Moving too quickly through the questions without fully reading them can lead to misunderstandings and mistakes. Take your time to carefully read each question.

- Second-guessing answers: Changing your answer multiple times can often lead to confusion. Trust your first instinct, but if you’re uncertain, skip and return to it later.

- Not managing time effectively: Not budgeting your time properly can result in not completing the exam. Allocate time for each section and keep track of your progress.

- Overlooking key details: Often, test questions include important details that can guide you to the correct answer. Pay attention to keywords, dates, and specifics that could be crucial.

How to Improve Performance

To minimize mistakes and improve your performance, consider these strategies:

- Practice with sample questions: Familiarize yourself with the types of questions you might encounter to reduce anxiety and increase confidence.

- Stay calm: Nervousness can impair your ability to think clearly. Take deep breaths and stay focused on the task at hand.

- Review your answers: If time allows, review your responses to ensure you haven’t overlooked any details or made unnecessary errors.

By avoiding these common mistakes and applying effective test-taking strategies, you’ll be better prepared for success.

How to Interpret Safety Guidelines

Understanding and applying safety guidelines is crucial for ensuring that all safety protocols are met in environments where consumables are handled. These guidelines are often based on regulatory standards that aim to protect both employees and customers. However, interpreting them correctly can sometimes be challenging due to the technical language and varying contexts. In this section, we will explore how to approach and understand these guidelines effectively to ensure compliance and maintain a safe working environment.

Key Steps in Interpretation

When reading safety protocols, consider the following approaches to help you navigate and apply them correctly:

- Identify the core message: Focus on the key point of each guideline. What is the main objective? Is it about cleanliness, temperature control, or employee hygiene?

- Look for context-specific instructions: Guidelines may be broad, but they can also include specifics for different situations or environments. Be sure to understand the context in which the rule applies.

- Understand technical terms: Some guidelines may use technical language. Take time to familiarize yourself with terms to avoid misunderstandings.

Applying Guidelines in Practice

Once you have interpreted the guidelines, it’s important to put them into practice effectively. Here are a few ways to do this:

- Regular training: Ensure that all team members are trained on interpreting and applying safety standards. This ensures consistency across the board.

- Continuous monitoring: Regularly check practices to make sure the guidelines are being followed, and correct any discrepancies immediately.

- Adapt to changing regulations: Guidelines can change over time, so it’s essential to stay informed and adjust your procedures accordingly.

By interpreting safety standards properly and applying them effectively, you can contribute to maintaining a high level of hygiene and safety in the workplace.

Training Resources for Safety Protocols

To ensure that all safety practices are followed effectively, proper training is essential. There are various educational tools and resources available for those looking to learn or improve their knowledge of hygiene standards and safety regulations. These resources range from online courses to in-person workshops, and they provide comprehensive guidance on maintaining a safe and healthy environment. This section will explore some of the most widely used training materials and how they can support compliance and best practices in the workplace.

Available Training Methods

Several types of training resources are available to support individuals in understanding and applying safety standards. These options offer flexibility and cater to different learning styles:

- Online Courses: Many institutions offer web-based courses that cover essential safety topics. These courses often include video tutorials, quizzes, and certification upon completion.

- Workshops and Seminars: Live, interactive sessions provide hands-on learning and real-time feedback from experts in safety practices.

- Printed Materials: Manuals, handbooks, and guides are available to provide clear instructions on essential practices and standards in a tangible format.

Comparing Training Resources

Each training method has its own set of advantages. The table below compares key features of these options to help you decide which best suits your needs:

| Resource Type | Pros | Cons |

|---|---|---|

| Online Courses | Flexible, self-paced, accessible anywhere | Requires internet access, lacks real-time interaction |

| Workshops/Seminars | Interactive, expert guidance, immediate feedback | Location and schedule dependent, limited availability |

| Printed Materials | Portable, useful for reference, easy to distribute | Not interactive, may require additional explanation |

By choosing the appropriate training resources, individuals and organizations can ensure that all staff are well-versed in maintaining a safe environment and adhering to safety protocols.

Who Can Issue Certification for Safety Practices?

The responsibility for issuing official documentation related to hygiene and safety practices lies with specific authorities and organizations. These entities ensure that individuals who handle essential tasks related to cleanliness and health protocols have undergone proper training and assessment. In this section, we will explore the various authorities and institutions empowered to issue certifications for safety compliance.

Authorized Institutions

Several organizations are authorized to grant the necessary documentation upon successful completion of relevant training or testing. These institutions are often accredited by government agencies or regulatory bodies to ensure that their programs meet safety standards.

- Local Health Departments: Many municipal and county health departments have the authority to certify individuals working in settings that require strict adherence to hygiene practices.

- State Regulatory Agencies: In some regions, state-level organizations oversee the issuance of certifications for individuals employed in sectors where health and safety are of high concern.

- Accredited Training Providers: Private institutions or online platforms offering recognized courses can also issue certification upon successful completion of their training programs.

Conditions for Issuance

While the specific requirements for certification can vary by location and authority, there are some common conditions that must be met:

- Completion of a Recognized Course: The individual must complete a program that has been accredited by a relevant authority or institution.

- Passing an Examination: Some certifications require individuals to pass a written or practical exam to demonstrate their knowledge of safety protocols.

- Meeting Health Standards: In certain cases, individuals may need to undergo a health screening to ensure they are fit to work in environments where sanitation is critical.

By understanding which organizations have the authority to issue certifications and the conditions for obtaining them, individuals can ensure that they meet all necessary requirements and are prepared for a successful career in safety-sensitive roles.

How to Maintain Certification Compliance

Maintaining compliance with industry standards is essential for individuals working in health-sensitive environments. This ensures not only personal proficiency but also the safety and well-being of those served. In order to stay compliant, it is necessary to follow certain guidelines and take periodic steps to stay updated with evolving practices and regulations.

One of the most crucial aspects of maintaining compliance is continuing education. Regularly updating one’s knowledge and skills is vital to keep up with changes in health and hygiene regulations. Below are several key strategies to remain compliant:

- Renewal of Certification: Many regions require individuals to renew their certification at regular intervals, often through refresher courses or by taking an updated exam.

- Stay Informed: Keep up with any updates to local or national health regulations. Authorities may issue guidelines or amendments that impact practices and protocols.

- Adherence to Standard Operating Procedures: Continuously follow established safety protocols within the workplace. Regular audits or inspections may be conducted to ensure ongoing compliance.

In addition to formal requirements, employers may provide training sessions or workshops designed to reinforce safe practices. Participation in these sessions can be beneficial for maintaining high standards and demonstrating a commitment to safety.

By adhering to these steps and remaining proactive, individuals can ensure that they continue to meet certification requirements and contribute to a safe and healthy environment for everyone involved.