In the world of food safety, knowledge is crucial for ensuring public health. Professionals working in the industry must demonstrate a deep understanding of hygiene practices, safe ingredient handling, and sanitation protocols. The certification process plays a vital role in assessing this expertise and ensuring that workers meet the required standards.

Preparing for the assessment requires focus on key concepts such as personal hygiene, contamination prevention, and safe cooking methods. It’s not just about memorizing facts; it’s about understanding the principles that keep food safe for consumers. This section provides you with essential information to help you confidently approach the test and perform at your best.

Mastering the material and applying best practices daily will lead to success in both the examination and your career. With the right study techniques and attention to detail, passing the assessment is within reach. Whether you’re new to the field or seeking to renew your certification, this guide will provide valuable insights and tips.

Certification Test Preparation Guide

Achieving certification in safety standards is an essential step for anyone working in the food industry. Success in this process hinges on a thorough understanding of key principles related to sanitation, personal hygiene, and safe ingredient handling. This section provides a structured approach to help you prepare effectively and confidently for the evaluation.

Start by focusing on the core topics that will be covered in the assessment. This includes proper cleaning techniques, preventing contamination, and safe temperature management. Be sure to study how these practices contribute to maintaining a healthy environment. A deep understanding of these concepts will not only help you pass the test but also ensure you’re ready for practical application in real-world situations.

Use reliable study materials and practice tests to familiarize yourself with the type of questions you may encounter. Consistent review and understanding the rationale behind each concept will give you a strong foundation for the certification process. Remember, preparation is key to building confidence and competence for long-term success in the field.

Understanding Safety Essentials

Proper safety practices are the foundation of a healthy environment, especially when handling consumables. A deep understanding of hygiene principles, contamination risks, and safe processing techniques is essential for anyone involved in the preparation, storage, and distribution of goods. This knowledge ensures that harmful pathogens are kept at bay and that best practices are followed to maintain the integrity of products.

To provide safe products and services, it’s vital to recognize the key factors that contribute to hygiene and safety. Below is a breakdown of core topics that form the basis of any safety program:

| Topic | Description |

|---|---|

| Personal Hygiene | Proper handwashing, grooming, and protective clothing to prevent contamination. |

| Temperature Control | Maintaining proper temperatures to prevent bacterial growth in perishable items. |

| Cross-Contamination Prevention | Using separate tools and equipment for raw and cooked items to avoid contamination. |

| Cleaning and Sanitizing | Regularly cleaning surfaces, utensils, and equipment to maintain a safe environment. |

Mastering these key areas will help create a safe space for both employees and consumers, ensuring that health regulations are met and maintained. Being well-versed in these essential principles is the first step toward achieving safety standards compliance in any environment.

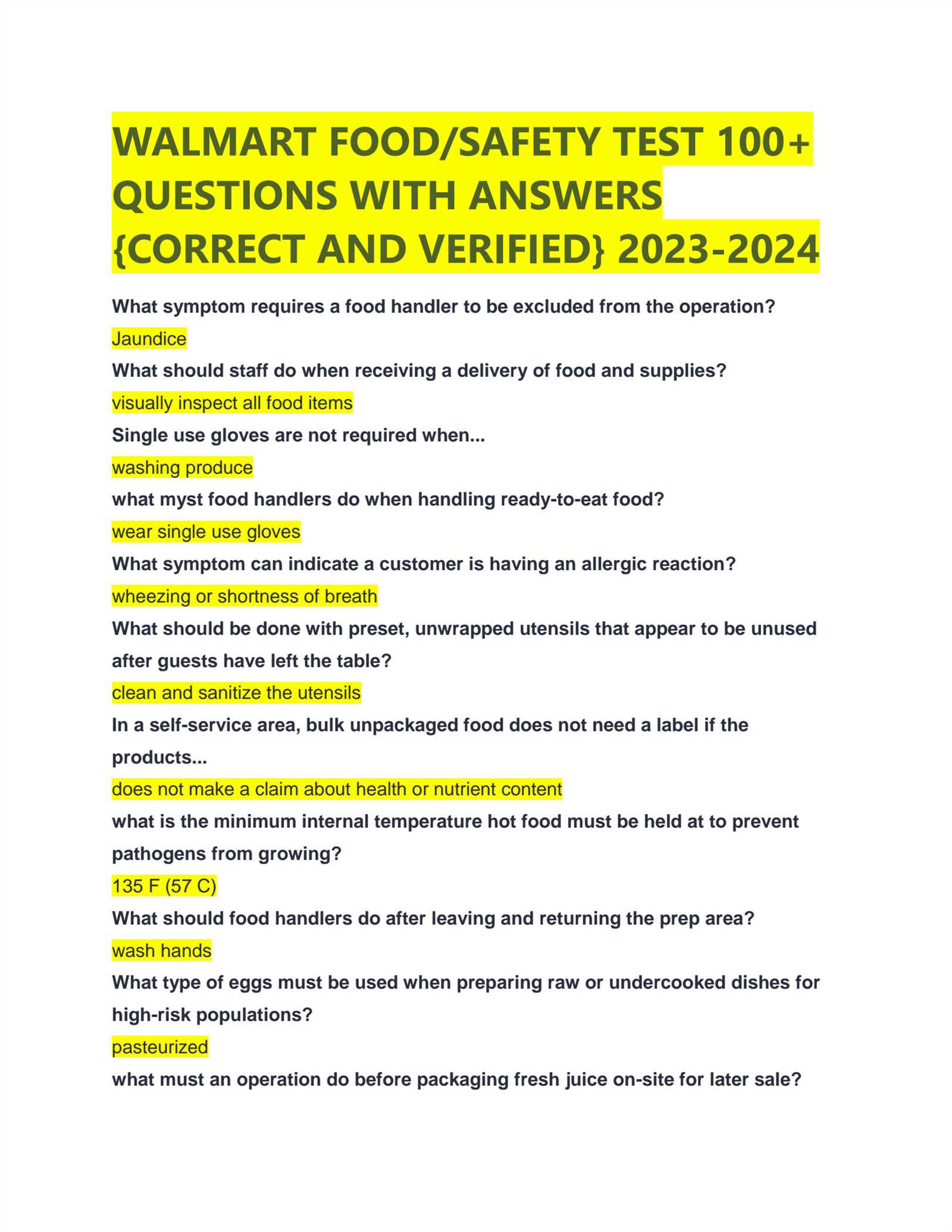

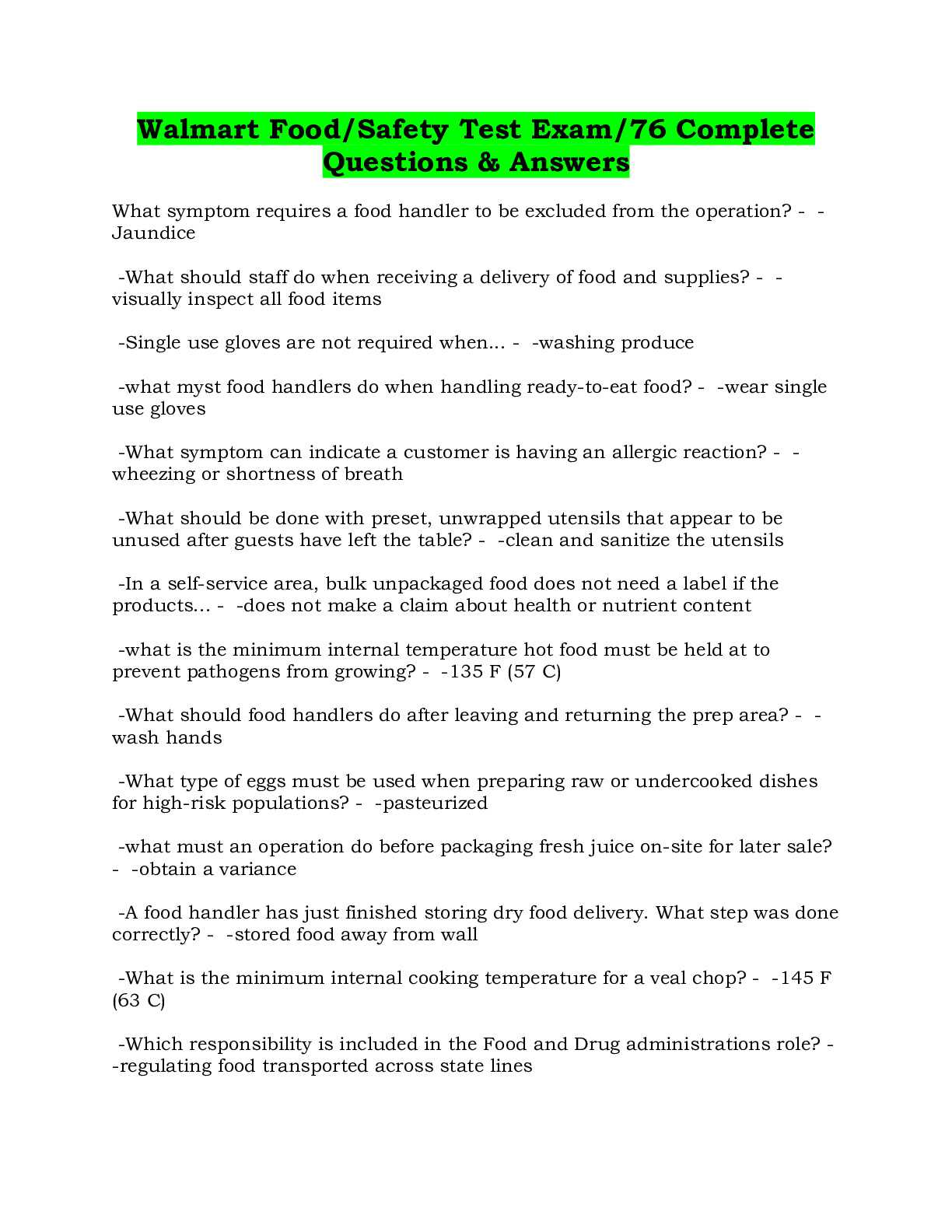

Key Topics in Certification Assessments

Understanding the core principles of safety and hygiene is crucial for anyone seeking certification in the industry. The topics covered in the evaluation reflect essential practices that are required to maintain a clean and healthy environment. By mastering these subjects, candidates ensure they are well-prepared to handle the challenges of working in environments where hygiene and safety are paramount.

Some of the key areas of focus include personal hygiene, cross-contamination prevention, and temperature control. These subjects are not only fundamental for passing the assessment but also for ensuring that individuals are capable of creating and maintaining a safe space for food preparation, storage, and service. Let’s break down these critical topics:

Personal Hygiene: Proper handwashing, wearing appropriate attire, and following health protocols to prevent the spread of bacteria are foundational to any safety program.

Cross-Contamination: Understanding the risks associated with mixing raw and cooked ingredients is essential for preventing illness. Knowledge of safe handling and separation techniques is necessary.

Temperature Management: Maintaining correct temperatures for storing, cooking, and serving items is vital to limit bacterial growth and ensure safe consumption.

Focusing on these key areas will not only enhance your preparation for the evaluation but also ensure that you can apply these principles in real-world settings, ensuring both safety and compliance with industry standards.

Common Questions on Hygiene Practices

When preparing for certification in hygiene standards, it’s essential to address some of the most common questions that arise about maintaining cleanliness and safety in the workplace. Understanding the answers to these questions will help you better apply the best practices necessary for protecting both staff and consumers. Below are several key topics that often cause confusion and require clear understanding.

How Do I Prevent Cross-Contamination?

One of the most critical aspects of hygiene is preventing cross-contamination between raw and cooked items. It is essential to use separate tools, surfaces, and containers for handling different types of ingredients. Thorough cleaning and sanitization are necessary after each use to eliminate any harmful bacteria that could be transferred. Additionally, storing ingredients at the correct temperature is crucial for minimizing risk.

What Are the Best Practices for Hand Hygiene?

Hand hygiene plays a vital role in preventing the spread of harmful pathogens. Workers must wash their hands with soap and water regularly, especially after handling raw materials, using the restroom, or touching contaminated surfaces. Proper handwashing involves scrubbing all areas of the hands for at least 20 seconds, ensuring the removal of any germs or bacteria that may be present.

These common questions are just a few of the many important aspects of hygiene. A thorough understanding of such practices will not only ensure compliance with health standards but also contribute to creating a safe environment for all individuals involved in food preparation and service.

Importance of Cross-Contamination Awareness

Cross-contamination is one of the most significant risks in environments where consumables are prepared, processed, or served. It occurs when harmful microorganisms are transferred from one surface or substance to another, leading to contamination. Awareness of this issue is crucial for maintaining a safe environment and preventing the spread of illness.

Preventing cross-contamination involves a combination of proper handling techniques, such as using separate utensils, equipment, and storage containers for different types of products. Regular cleaning and sanitizing of surfaces, tools, and hands are essential steps in minimizing the risk of harmful bacteria being transferred between ingredients. Implementing these practices reduces the chances of exposure to foodborne illnesses.

By understanding the dangers of cross-contamination and taking proactive measures to prevent it, individuals can create a safer environment for everyone. This awareness not only helps in complying with safety standards but also builds trust with customers and consumers, ensuring the overall health and well-being of those who rely on these services.

Personal Hygiene Rules for Workers

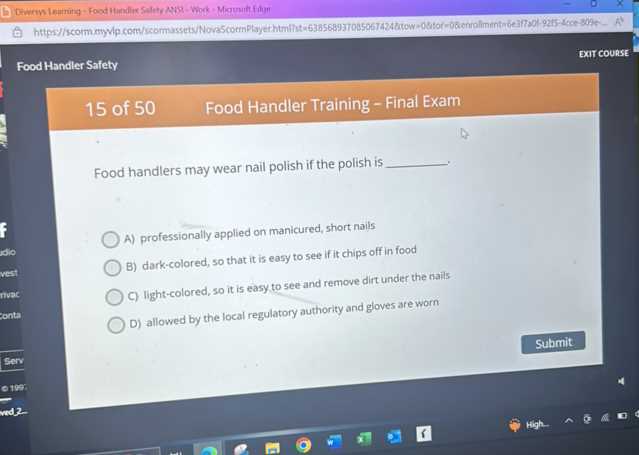

Maintaining proper personal hygiene is essential in ensuring a safe environment, especially in settings where consumables are prepared and served. Hygiene practices protect not only the worker but also the consumers by reducing the spread of harmful bacteria and viruses. Strict adherence to hygiene standards is a fundamental requirement in any industry dealing with consumables.

Key Hygiene Practices

Personal cleanliness begins with regular handwashing, which should be done thoroughly with soap and warm water for at least 20 seconds. Hands should be washed before handling any ingredients, after using the restroom, or after touching any potentially contaminated surfaces. Additionally, nails should be trimmed and clean, and workers should avoid touching their faces while working.

Proper Work Attire

Workers must wear clean, protective clothing, including aprons and gloves, to prevent any potential contamination of products. Hair should be neatly tied back or covered with a hairnet to avoid shedding into the environment. Personal items such as jewelry or watches should be avoided, as they can trap bacteria and cause contamination. Ensuring a clean appearance is not only a safety measure but also a professional standard.

By following these hygiene rules, workers contribute to a safer and more sanitary environment, helping to reduce the risk of illness and maintain industry standards. These practices are critical in ensuring public health and building trust in the services provided.

Temperature Control in Safety

Maintaining the correct temperature is crucial in preventing the growth of harmful microorganisms in perishable products. Whether storing, cooking, or serving items, temperature control ensures that harmful bacteria do not thrive and cause illnesses. This practice is essential for maintaining hygiene standards and guaranteeing the safety of all items that come into contact with consumers.

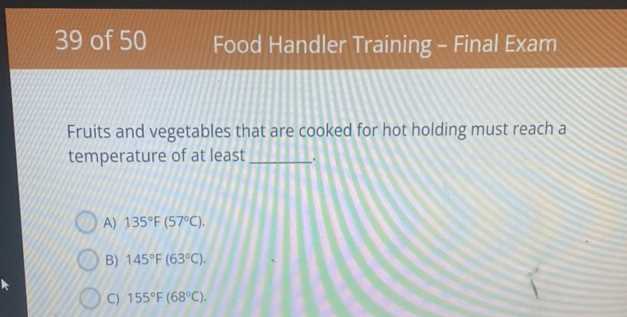

The key to effective temperature control is knowing the proper ranges for different stages, such as storing, cooking, and holding. Below is a summary of the temperature zones that must be carefully monitored:

| Temperature Zone | Action |

|---|---|

| Danger Zone (41°F – 135°F / 5°C – 57°C) | Temperature range where harmful bacteria multiply rapidly. Items should not be stored or held in this range for extended periods. |

| Cold Storage ( | Items should be kept at or below this temperature to prevent bacterial growth and maintain freshness. |

| Hot Holding (> 135°F / > 57°C) | Items should be kept at this temperature or higher to keep them safe for consumption and prevent contamination. |

By understanding and applying proper temperature control techniques, workers can significantly reduce the risk of contamination and ensure the safe handling of all items. Regular checks with thermometers and monitoring tools are essential to maintaining these safety standards consistently.

Identifying Illnesses from Contamination

Recognizing the symptoms of illnesses caused by contamination is essential for ensuring a safe environment, especially when dealing with consumables. These illnesses can arise from bacteria, viruses, or parasites and can have a serious impact on health. Early detection of symptoms can help prevent the spread of illness and ensure prompt treatment.

Common Symptoms of Contamination

The signs of contamination-related illnesses vary, but some common symptoms include nausea, vomiting, diarrhea, and stomach cramps. In more severe cases, fever, dehydration, and blood in stool may also be present. It’s crucial to be aware of these symptoms and understand when they may indicate contamination or an outbreak.

Common Contaminants and Their Effects

Salmonella is one of the most common bacterial causes of contamination, leading to symptoms like diarrhea, fever, and abdominal cramps. Norovirus, a viral contaminant, can cause similar symptoms but is highly contagious. Other pathogens, such as E. coli and Listeria, can also lead to serious health issues and must be handled with extreme care.

Proper hygiene practices, including frequent handwashing and maintaining correct storage temperatures, are vital for minimizing the risk of these illnesses. By understanding the causes and symptoms of contamination-related illnesses, workers can help prevent outbreaks and protect both their health and the health of consumers.

Proper Handling of Raw Ingredients

Handling raw materials requires careful attention to prevent contamination and ensure safety throughout the preparation process. These ingredients often carry harmful pathogens that can easily spread to other items if not properly managed. By following specific protocols, workers can significantly reduce the risk of contamination and ensure a safe environment for consumers.

Preventing Cross-Contamination

To prevent cross-contamination, it is essential to use separate tools, cutting boards, and storage containers for raw ingredients. This includes keeping raw and cooked items apart at all stages of preparation. Additionally, workers must ensure that raw materials are stored at the correct temperatures to minimize the growth of harmful microorganisms.

Proper Washing and Handling Techniques

Before handling raw ingredients, workers must wash their hands thoroughly with soap and water. It is also important to regularly clean and sanitize all surfaces and equipment that come into contact with raw items. When handling perishable materials, gloves should be worn to reduce the risk of transferring bacteria from hands to the ingredients.

By implementing these safety measures, workers can prevent the spread of harmful bacteria and maintain a hygienic and safe environment. Proper handling of raw ingredients is essential for safeguarding both the preparation process and the health of the consumers.

Cleaning and Sanitizing Techniques

Maintaining a clean and sanitary environment is vital to ensure safety and prevent contamination. Proper cleaning and sanitizing techniques are essential for eliminating harmful microorganisms from surfaces, tools, and equipment. These practices help maintain hygiene standards and reduce the risk of illness in environments where consumables are prepared and served.

Steps for Effective Cleaning

Cleaning involves removing dirt, debris, and visible impurities from surfaces. The following steps should be followed for effective cleaning:

- Remove any large debris or food particles from the surface.

- Use warm water and detergent to scrub the area thoroughly.

- Rinse the surface to remove any soap residue.

Sanitizing After Cleaning

Sanitizing goes a step further, killing harmful bacteria and viruses that may remain on cleaned surfaces. After cleaning, use an appropriate sanitizing solution, following the manufacturer’s instructions for proper dilution and application. Here are key points to remember when sanitizing:

- Choose a sanitizing agent that is effective against the most common pathogens.

- Apply the solution to cleaned surfaces and allow it to sit for the recommended contact time.

- Ensure that sanitized surfaces are left to air dry or wipe with a clean cloth.

By using these techniques regularly, workers can create a safer and healthier environment, minimizing the risk of contamination and ensuring a high standard of hygiene in all areas where ingredients are handled or prepared.

Storage Best Practices

Proper storage of ingredients and supplies is essential to maintaining quality and preventing contamination. Whether items are perishable or non-perishable, correct storage methods help preserve their safety and extend shelf life. These best practices ensure that materials are kept in optimal conditions and that harmful microorganisms do not proliferate.

General Storage Guidelines

To avoid spoilage and cross-contamination, follow these general storage tips:

- Store perishable items in the correct temperature range, either chilled or frozen, to prevent bacterial growth.

- Keep raw and ready-to-eat items separate to prevent cross-contamination.

- Label all items with expiration dates and ensure they are used within their shelf life.

- Use proper containers that are clean, sealed, and food-safe to prevent exposure to contaminants.

Special Considerations for Different Materials

Different items require specific storage considerations to maintain safety and quality:

- Dry goods: Store in cool, dry, and dark environments to prevent spoilage. Keep items off the floor and away from walls.

- Cold storage: Ensure refrigerators and freezers are at the correct temperature and regularly monitored to ensure efficiency.

- Canned and jarred products: Store in a cool, dry location away from direct sunlight. Ensure that containers are undamaged and sealed properly.

Adhering to these storage practices minimizes the risk of contamination and maintains the quality of all ingredients, ensuring safety and satisfaction for consumers.

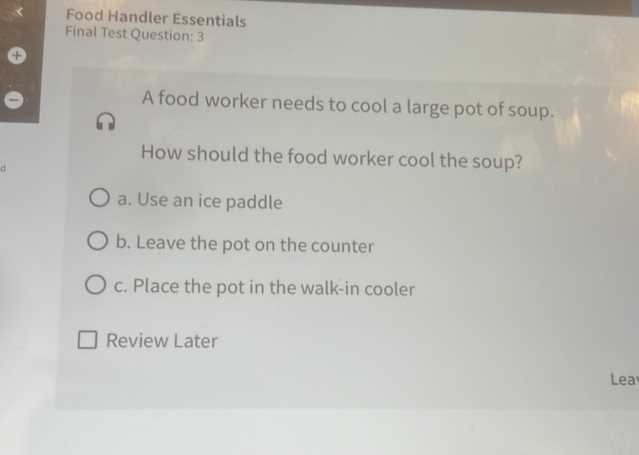

Exam Strategies for Certification

Preparing for a certification test in safety and hygiene requires a focused approach. Understanding key concepts, practicing effective recall, and managing time during the assessment are crucial elements for success. By following proven strategies, individuals can increase their chances of passing and gaining the certification needed for professional work in this field.

Start by thoroughly reviewing the material related to hygiene, safety practices, and proper procedures. Focus on understanding, rather than memorizing, to ensure you can apply the knowledge in real-world situations. It is also helpful to take practice tests to familiarize yourself with the format and types of questions that may appear during the assessment.

In addition to preparation, good test-taking strategies will help optimize performance. Read each question carefully and take your time to answer. Eliminate clearly wrong answers to increase your chances of selecting the right one. Stay calm, stay focused, and approach the test with confidence.

Understanding Allergens Regulations

Recognizing and managing allergens is a critical aspect of maintaining a safe environment for consumers. Regulations surrounding allergens are designed to protect individuals with sensitivities and prevent adverse reactions. Adhering to these rules ensures that allergens are properly disclosed, handled, and prevented from contaminating products that may otherwise be safe for general consumption.

Different regions have established specific requirements regarding allergen labeling, storage, and preparation practices. Understanding and following these guidelines is essential for both safety and compliance in any setting where consumables are prepared or served.

Key Regulations to Follow

- Ensure that all potential allergens are clearly identified and labeled on products.

- Store allergenic ingredients separately to prevent cross-contact with non-allergenic items.

- Regularly train staff on how to recognize, handle, and communicate allergen risks to consumers.

- Maintain strict sanitation practices to reduce the risk of cross-contamination.

Common Allergens to Watch For

Some of the most common allergens that must be carefully monitored include:

- Peanuts

- Tree nuts

- Shellfish and fish

- Eggs

- Milk

- Wheat

- Soy

By understanding the legal requirements and properly managing allergenic ingredients, businesses and individuals help ensure a safer environment for everyone, including those with sensitivities.

Certification Requirements for Safety Professionals

Obtaining certification in safety practices is essential for professionals working in environments where consumables are prepared, handled, or served. This certification ensures that individuals have the necessary knowledge and skills to maintain hygiene and prevent contamination. The certification process is designed to help professionals understand essential principles of safety, sanitation, and proper handling techniques.

In order to meet certification requirements, candidates typically need to complete an accredited training program that covers the most relevant topics in sanitation, contamination prevention, and safe practices. Successful completion of the training program is often followed by an assessment or test to verify the understanding of key concepts.

Core Requirements for Certification

- Completion of an accredited training course covering essential safety and sanitation practices.

- Passing a written test or assessment that evaluates the understanding of proper procedures and rules.

- Ongoing education to stay up to date with the latest regulations and best practices in safety management.

- Certification may require renewal after a certain period, typically 3-5 years, depending on local regulations.

Training Topics to Expect

- Basic hygiene and sanitation principles

- Identification and management of allergens

- Preventing cross-contamination and handling raw materials safely

- Temperature control and its importance in safety

- Recognizing common health risks and illness prevention

By fulfilling these requirements, individuals demonstrate their commitment to maintaining a safe and sanitary environment, essential for protecting public health and ensuring compliance with regulations.

Best Resources for Study Preparation

Effective preparation for safety certification assessments is crucial for mastering essential concepts related to sanitation, hygiene, and proper procedures. With a wide range of materials available, selecting the most relevant and reliable resources can make a significant difference in achieving success. Utilizing the best study aids will not only help with understanding key topics but also enhance recall during assessments.

To achieve the best results, candidates should consider a combination of study guides, online courses, practice tests, and reference materials. These resources cover all the necessary topics, providing both theoretical knowledge and practical application. By using diverse learning methods, individuals can better grasp the concepts required for certification.

Recommended Study Guides and Books

- Official Safety Handbooks: Many certification programs offer official handbooks that cover all essential topics in detail. These are great for understanding core principles.

- Study Guides: Comprehensive study guides are available that condense the key information, making it easier to review before an assessment.

- Textbooks: Books on hygiene, food safety, and sanitation provide in-depth knowledge, with more advanced explanations and examples.

Online Learning Platforms

- Interactive Courses: Websites like Coursera and Udemy offer interactive courses that cover essential safety practices, with video lectures and quizzes to help reinforce learning.

- Mobile Apps: Many apps are designed to help users learn on the go. These apps often include practice questions and real-time feedback.

- Practice Tests: Some platforms provide practice exams to simulate real-life assessments, allowing candidates to gauge their readiness.

By leveraging a combination of these resources, candidates can approach their certification with confidence and well-rounded knowledge, ready to pass the assessment and apply their skills in real-world scenarios.

Tips for Passing the Certification Assessment

Successfully passing a safety certification test requires thorough preparation, focus, and effective strategies. The key to achieving a high score lies not only in understanding the material but also in applying good study habits, managing time wisely, and practicing with sample questions. By following the right techniques, you can approach the assessment with confidence and ensure your success.

One of the most effective strategies is to break down the study material into manageable chunks. Avoid cramming and give yourself plenty of time to review each topic. Practice with mock tests to familiarize yourself with the types of questions you will encounter. Time management is also crucial–ensure you have enough time to read and understand each question before answering.

Effective Study Techniques

- Review Key Concepts: Focus on the fundamental principles of safety, hygiene, and sanitation. These topics are the foundation of the test.

- Use Flashcards: Flashcards are great for memorizing definitions, terms, and concepts that are likely to appear on the test.

- Take Practice Quizzes: Use online resources or study guides to test your knowledge under timed conditions.

Test-Taking Strategies

- Read Questions Carefully: Make sure you understand what each question is asking before selecting an answer.

- Don’t Rush: Pace yourself throughout the assessment. Rushing can lead to mistakes.

- Eliminate Incorrect Answers: If unsure about an answer, try eliminating the obviously incorrect options to improve your chances.

By using these tips, you can optimize your preparation and boost your chances of passing the certification test. Approaching the assessment with the right mindset and preparation will increase your confidence and lead to a successful outcome.