Understanding the essential practices for maintaining a safe environment is crucial for everyone working with consumables. This section focuses on key principles that ensure hygiene, prevent contamination, and promote health standards. By mastering these core concepts, individuals can contribute to a safer workplace while meeting industry requirements.

Proper procedures for handling materials, avoiding hazards, and maintaining cleanliness are vital. These practices not only prevent potential risks but also help in complying with regulatory standards. As part of the training process, understanding these principles will prepare individuals for certification and compliance checks.

Knowledge of common pitfalls and how to avoid them can make a significant difference in achieving a successful outcome. This guide offers insights into the most important elements of safe practices, equipping you with the tools needed to excel in your certification process.

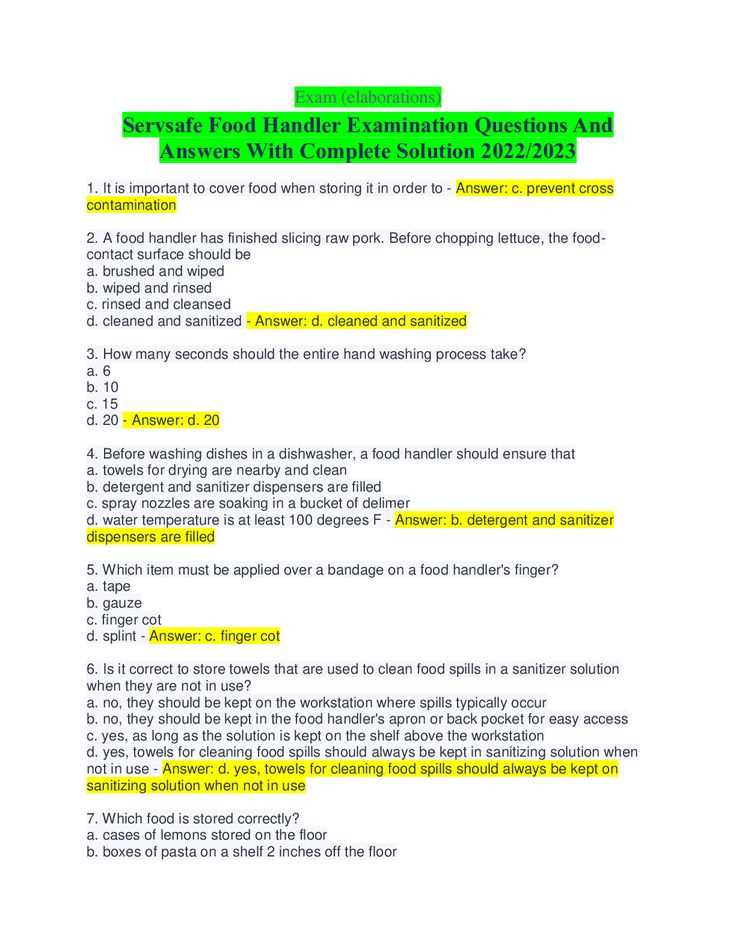

Food Handler Exam Lesson 9 Answers

This section covers the key principles and practices necessary for passing the crucial assessment of safe workplace practices. It focuses on important concepts related to hygiene, contamination prevention, and health regulations, which are central to ensuring safety in environments handling consumables. Mastering these concepts is essential for passing the certification process and maintaining compliance with industry standards.

By thoroughly reviewing these key topics, candidates can better prepare for the questions that typically appear in the final evaluation. Below are some of the core concepts that will be addressed in the review process:

- Correct hygiene practices to minimize health risks

- Techniques for avoiding contamination and cross-contamination

- Proper storage and handling of materials

- Maintaining temperature control for safety

- Understanding allergen management in various environments

In the following sections, you’ll find detailed explanations of each topic, along with useful tips for navigating the assessment effectively. Review these key areas to ensure you are fully prepared for the final test.

- Understanding key health and safety practices

- Identifying common hazards and contamination risks

- Mastering the proper use of protective equipment

- Reviewing essential storage guidelines for safety

- Exploring the importance of temperature regulation

Preparing for the certification process involves not only memorizing specific facts but also understanding the underlying principles that ensure safety in the workplace. The following sections will help you refine your knowledge and increase your confidence in passing the certification assessment.

Key Topics Covered in Lesson 9

This section delves into the essential concepts that ensure safety and hygiene in environments where consumables are handled. These topics form the backbone of maintaining high standards and preventing health risks. Understanding each concept thoroughly will prepare you for real-world situations and help you pass any relevant evaluations.

The main areas of focus include:

- Proper sanitation techniques to minimize risks

- Prevention of contamination through correct practices

- Safe storage and handling of products to avoid spoilage

- Temperature control to preserve safety and quality

- Understanding allergens and managing them effectively

- Using protective equipment to reduce exposure to hazards

In the upcoming sections, each of these critical areas will be explored in detail, providing you with the knowledge needed to ensure a safe and compliant environment. Mastery of these topics is crucial not only for certification but for creating a secure working atmosphere.

- Hygiene standards for all workers in critical roles

- Key risks in environments that deal with consumables

- Identifying and managing potential contamination sources

- Understanding the significance of temperature in safety

- Guidelines for effective allergen control

Familiarizing yourself with these core principles will give you a solid foundation for achieving certification and applying best practices in any related field.

Understanding Safety Principles

Ensuring the highest standards of cleanliness and care is vital in any environment where consumables are involved. This section focuses on the fundamental practices that contribute to a safe and healthy atmosphere. By adhering to these principles, workers can significantly reduce the risk of contamination and promote well-being across all stages of preparation and service.

Hygiene practices form the foundation of safety in any setting. Workers must maintain clean hands, surfaces, and equipment to prevent the spread of harmful microorganisms. Regular cleaning and sanitizing are essential, especially in areas that come into direct contact with consumables.

Temperature management is another critical aspect of safety. Properly storing and cooking products at the right temperatures helps preserve their quality and prevents the growth of harmful bacteria. Consistently monitoring temperatures ensures that health standards are met, and spoilage risks are minimized.

By following these core safety principles, you create a safer environment for everyone involved, from workers to consumers. Understanding these practices is essential for maintaining compliance with health regulations and ensuring the well-being of all parties.

Importance of Proper Hygiene Practices

Maintaining cleanliness in any environment is crucial to preventing contamination and ensuring the safety of all individuals involved. Proper hygiene practices help to reduce the spread of harmful bacteria and other pathogens that can lead to illnesses. These practices must be followed consistently to uphold health standards and avoid any potential risks.

Key hygiene practices include regular hand washing, cleaning work surfaces, and ensuring that protective gear is properly worn. These simple but effective actions can prevent the transfer of harmful microorganisms from one surface to another, significantly reducing the chances of contamination.

| Hygiene Practice | Importance | Frequency |

|---|---|---|

| Hand washing | Prevents the spread of harmful bacteria | Before and after handling materials |

| Cleaning surfaces | Reduces contamination risk | Regularly throughout the day |

| Wearing protective gear | Minimizes exposure to potential hazards | Whenever handling materials |

| Proper disposal of waste | Prevents accumulation of harmful substances | As needed |

By understanding the importance of hygiene, individuals contribute to a healthier, safer environment. Regular adherence to these practices is essential to maintaining high standards of safety and compliance in any workplace.

Common Illnesses and Prevention

In environments where consumables are handled, understanding the most common illnesses and their prevention is essential for maintaining a safe and healthy space. Various pathogens can cause illnesses that are often transmitted through improper handling, storage, or preparation. Recognizing these risks and taking preventive measures significantly lowers the chances of outbreaks.

Some of the most common illnesses caused by improper practices include bacterial infections like salmonella and E. coli, as well as viral infections such as norovirus. By understanding how these pathogens spread and the methods for preventing contamination, workers can help ensure a safe environment for all.

| Illness | Cause | Prevention |

|---|---|---|

| Salmonella | Improperly cooked or contaminated poultry | Cook to proper temperature, avoid cross-contamination |

| E. coli | Undercooked ground meats, unclean water | Ensure thorough cooking, wash hands and surfaces |

| Norovirus | Contaminated food or surfaces | Frequent hand washing, sanitizing surfaces |

| Campylobacter | Raw or undercooked meat, especially poultry | Cook meat thoroughly, avoid cross-contact |

By following proper guidelines for cleaning, cooking, and handling, the risk of these illnesses can be minimized. Implementing these preventive measures ensures the safety of both workers and consumers, promoting a healthier environment overall.

Food Handling Techniques Explained

Proper handling techniques are essential to maintain safety and prevent contamination in environments where consumables are prepared and served. These methods ensure that materials are handled in a way that preserves their quality and minimizes the risk of harmful bacteria or other pathogens. Understanding and implementing these techniques is critical for creating a safe and compliant environment.

Some of the key techniques for safe handling include:

- Proper handwashing – Always wash hands thoroughly before handling materials and after any potential contamination.

- Correct storage practices – Store materials at the right temperature to prevent spoilage and growth of bacteria.

- Separation of raw and ready-to-eat items – Keep raw items separate to avoid cross-contamination.

- Use of protective equipment – Wear gloves, aprons, and masks as necessary to prevent direct contact with materials.

- Maintaining cleanliness of surfaces – Regularly sanitize countertops, utensils, and equipment to reduce contamination risks.

These techniques play a significant role in maintaining a safe and healthy environment. By consistently applying these practices, individuals can effectively reduce the risk of foodborne illnesses and ensure that proper hygiene standards are met.

In addition to these basic practices, there are advanced handling techniques that are essential for higher-risk materials and situations. Training and continuous education on these methods are important for workers to stay updated and compliant with safety standards.

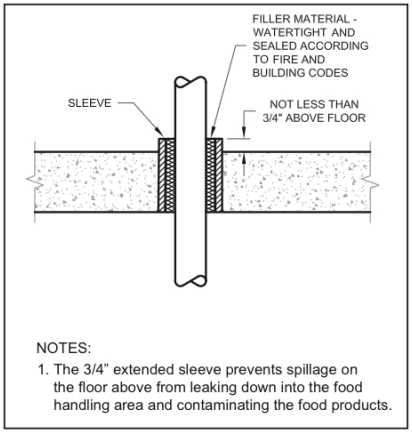

Critical Points for Safe Storage

Proper storage is crucial for maintaining safety and preventing contamination in environments where consumables are handled. Ensuring that materials are kept in the right conditions helps prevent spoilage, bacterial growth, and cross-contamination. Understanding the critical points for safe storage is essential to uphold hygiene standards and protect public health.

One of the most important factors in safe storage is temperature control. Keeping materials at the correct temperatures slows down the growth of harmful microorganisms and ensures their safety. For example, perishable items should be stored in refrigerators or freezers, while dry goods should be kept in a cool, dry place.

Another key point is proper organization. Keeping different types of materials separated, particularly raw and ready-to-eat items, reduces the risk of contamination. Using labeled storage containers and maintaining clear inventory systems ensures that materials are used within their safe shelf life.

Regular checks for expiration dates and signs of spoilage are also essential. Discarding any items that have gone bad or are past their expiration date helps prevent the spread of illness and maintains the overall safety of the environment.

Temperature Control in Food Safety

Temperature regulation is a fundamental aspect of maintaining a safe environment when handling consumables. Proper temperature control slows down or halts the growth of harmful microorganisms, preventing potential health risks. It is essential to store, cook, and serve items at the correct temperatures to ensure they remain safe for consumption.

Hot items should be kept at temperatures above 140°F (60°C) to prevent bacteria from multiplying, while cold items must be stored at or below 41°F (5°C) to inhibit growth. These temperature ranges are critical in maintaining the safety and quality of materials throughout their lifecycle.

Monitoring temperatures consistently is essential. Using reliable thermometers and regularly checking storage and cooking areas ensures compliance with safety standards. Additionally, staff must be trained to understand the importance of these regulations and the potential consequences of neglecting them.

By maintaining strict temperature controls, businesses can minimize the risk of contamination and ensure that materials are safe for consumption. Regular audits and continuous monitoring are key components in upholding these standards over time.

Personal Protective Equipment Requirements

Ensuring safety in environments where consumables are prepared and handled requires the use of appropriate protective gear. Personal protective equipment (PPE) serves as a barrier between potential contaminants and workers, reducing the risk of exposure to harmful substances and maintaining hygiene standards. The proper use of PPE is crucial for protecting both the individual and the materials being handled.

Common types of protective equipment include gloves, aprons, face masks, and hair coverings. Each item serves a specific purpose, such as preventing direct contact with materials, containing airborne particles, or keeping personal hygiene intact. It is essential that workers understand the proper usage and disposal of PPE to maximize its effectiveness.

Training in the proper use and maintenance of protective gear is vital for compliance with health and safety regulations. PPE should be worn at all appropriate times, especially when handling sensitive or potentially hazardous materials. Regular inspections of gear, along with prompt replacement when damaged, ensure that it continues to provide effective protection.

Contamination and Cross-Contamination

Contamination occurs when harmful microorganisms or substances are introduced into consumable materials, posing a risk to health. It can happen through direct contact or environmental factors, making it essential to understand how contamination occurs and the measures to prevent it. Cross-contamination, a specific type of contamination, happens when harmful agents are transferred from one item to another, often through improper handling or inadequate sanitation practices.

Cross-contamination is especially dangerous because it can easily spread pathogens from raw items to those that are ready to eat. This can happen through shared utensils, cutting boards, or surfaces that have not been properly sanitized. It’s crucial to segregate items based on their risk and ensure that high-risk items are kept separate from those that are less vulnerable to contamination.

Preventing contamination involves several key practices, including proper cleaning and sanitizing of surfaces, using different tools for raw and ready-to-eat materials, and ensuring that all workers follow strict hygiene protocols. Regular training and adherence to safety standards significantly reduce the chances of contamination and help maintain a safe environment for both workers and consumers.

Allergen Management in Food Handling

Effective management of allergens is essential to ensure the safety of individuals with specific sensitivities. When handling materials, it is crucial to prevent exposure to allergens that could cause severe reactions. This involves identifying, labeling, and properly storing items to reduce the risk of accidental exposure. Understanding the potential sources of allergens and how they can spread is vital for maintaining a safe environment.

One of the primary methods of allergen control is proper labeling. Clearly identifying allergenic ingredients in materials allows workers and consumers to make informed decisions and avoid potentially harmful exposure. Additionally, cross-contact prevention techniques should be implemented, such as using dedicated equipment for allergen-containing materials and sanitizing surfaces between uses.

Training staff to recognize and handle allergens safely is another important aspect. Workers should be aware of the procedures for managing allergic reactions, including how to respond to an emergency. By prioritizing allergen management, businesses can create a safer environment for everyone and comply with health and safety regulations.

Employee Training and Safety Protocols

Ensuring that employees are properly trained is fundamental to maintaining a safe working environment. Proper training not only equips staff with the necessary knowledge and skills to handle materials safely but also fosters a culture of responsibility. Well-defined safety protocols are crucial to minimize the risk of accidents, injuries, or contamination.

Training Programs

A comprehensive training program should cover essential safety practices, emergency response procedures, and hygiene standards. Employees need to understand the potential hazards they may encounter and how to address them effectively. Regular refresher courses and updates on new safety guidelines ensure that the team remains well-informed and prepared.

Importance of Safety Protocols

Clear and consistent safety protocols must be implemented to guide employees in their daily tasks. These protocols include proper personal protective equipment (PPE) usage, correct handling techniques, and sanitation measures. When followed correctly, these protocols reduce the chances of contamination, accidents, and health risks. It is crucial that every team member is aware of and adheres to these safety guidelines to ensure a secure environment for all involved.

How to Pass Your Certification Test

Successfully passing a certification test requires thorough preparation and a clear understanding of the subject matter. The process involves studying the key principles of safety, hygiene, and proper procedures to ensure that all practices are followed correctly. The more familiar you are with the materials and regulations, the more confident you’ll feel during the test.

One of the most effective ways to prepare is to review practice questions and test materials. These resources help familiarize you with the types of questions you will encounter, and they highlight the most important topics. Focus on key concepts, such as safety protocols, risk prevention, and proper handling techniques. Understanding these principles is essential for passing the test and applying them in real-world situations.

Another helpful strategy is to participate in training programs or review courses. These programs often offer detailed explanations of complex topics and allow you to ask questions about any areas where you may need more clarity. Remember that passing this test not only demonstrates your knowledge but also your commitment to maintaining a safe and hygienic environment.

Review of Key Concepts

In this section, we will revisit the fundamental principles covered in the previous module. These concepts form the foundation for creating and maintaining a safe and hygienic environment in any setting where materials are handled. By reviewing these critical areas, you can ensure you understand the key practices and procedures needed to prevent hazards and ensure safety.

Key Principles of Hygiene

Maintaining cleanliness and hygiene is essential for preventing contamination and ensuring a safe working environment. This includes understanding how to properly sanitize surfaces, handle equipment, and protect yourself from exposure to harmful agents.

| Concept | Action |

|---|---|

| Personal Hygiene | Regular hand washing, wearing clean clothing, and using protective gear. |

| Surface Sanitation | Proper cleaning of work areas, tools, and equipment to prevent cross-contact. |

| Waste Management | Safe disposal of waste materials to prevent contamination. |

Risk Prevention and Control

Identifying potential risks and knowing how to control them is vital for maintaining safety. This involves understanding how to handle materials safely, avoid cross-contact, and reduce the risk of exposure to harmful substances. Knowing when and how to implement control measures is crucial in keeping a safe environment for all involved.

Questions You Should Expect

When preparing for your certification assessment, it’s important to familiarize yourself with the types of questions that may appear. These questions are designed to test your understanding of essential principles and practices, focusing on safety, hygiene, and risk prevention. Knowing what to expect can help you focus on the most critical areas and ensure you are ready for the test.

Types of Questions

Questions typically cover a variety of topics related to the safe handling of materials, personal protection, sanitation, and risk management. Below are some common question types you might encounter:

- Multiple Choice: These questions assess your knowledge of key concepts by asking you to choose the correct answer from several options.

- True/False: You will need to determine whether a statement about safety procedures or hygiene practices is correct or incorrect.

- Scenario-Based: These questions present a real-world situation and ask you to choose the best course of action based on safety and hygiene standards.

Key Areas to Focus On

While the specific questions will vary, the following topics are commonly tested:

- Personal Hygiene: Proper handwashing, use of protective equipment, and maintaining cleanliness in the workspace.

- Sanitation Practices: Cleaning and disinfecting surfaces, tools, and equipment to prevent contamination.

- Risk Prevention: Identifying hazards and implementing control measures to minimize risks in the environment.

- Temperature Control: Understanding the safe temperature ranges for storing and handling materials to prevent spoilage or contamination.

By focusing on these key areas, you will be better equipped to answer the questions and demonstrate your understanding of safe practices.

Common Mistakes in Food Handling Exams

Many individuals make common errors during certification assessments, which can negatively impact their performance. These mistakes often stem from a lack of understanding or oversight of critical principles. By being aware of these frequent pitfalls, you can avoid them and improve your chances of success. Below are some of the most common mistakes made during assessments and tips on how to prevent them.

1. Neglecting Personal Hygiene Standards

One of the most frequent mistakes is overlooking the importance of personal cleanliness. This includes improper handwashing, failure to wear protective gear, or neglecting to maintain clean clothing and tools. To avoid this error, always adhere to proper hygiene practices and be sure to emphasize the significance of cleanliness in your daily routine.

2. Misunderstanding Temperature Guidelines

Another common mistake is misinterpreting or forgetting the correct temperature requirements for storing and handling materials. Whether it’s keeping items within safe temperature ranges or understanding how long items can safely remain at certain temperatures, having a clear grasp of temperature control is essential for passing the test.

3. Failing to Identify Hazards

Inability to identify potential risks is another major mistake. You must be able to recognize common hazards, such as contamination sources, allergens, or equipment malfunctions. Understanding how to mitigate these risks is critical and should be a focus during your study sessions.

4. Overlooking Cleaning and Sanitizing Procedures

Many individuals fail to properly emphasize the importance of sanitizing equipment, surfaces, and utensils. It’s crucial to understand the proper procedures for maintaining a sanitized environment. Failing to follow cleaning protocols could lead to contamination, which is why it’s vital to focus on these areas during your preparation.

5. Incomplete Knowledge of Regulations

Not being fully aware of regulations and guidelines is another mistake. It’s important to have a comprehensive understanding of the standards set by governing bodies to ensure that your practices align with legal requirements. Be sure to study these regulations and familiarize yourself with common policies.

By addressing these common mistakes, you can approach your certification with confidence and improve your understanding of safe practices.

Test-Taking Tips for Food Handler Exams

Successfully passing a certification test requires not only knowledge but also the right strategies. In order to perform well, it’s essential to approach the test with confidence and clarity. Below are some practical tips to help you navigate the process and achieve a high score.

1. Prepare in Advance

- Study Regularly: Begin studying well ahead of the test date. Review key concepts and regulations regularly to reinforce your understanding.

- Use Practice Questions: Practice answering sample questions to familiarize yourself with the format and types of questions that will appear on the test.

- Understand the Key Topics: Focus on understanding the fundamental principles that are likely to be tested. These include safety protocols, hazard identification, and proper procedures.

2. Test-Taking Strategies

- Read Questions Carefully: Pay close attention to the wording of each question. Misinterpreting questions can lead to unnecessary mistakes.

- Manage Your Time: Allocate time for each section of the test. Don’t spend too long on one question, and ensure you leave enough time to review your answers.

- Eliminate Wrong Answers: If you’re unsure about an answer, try eliminating the clearly incorrect options first. This increases your chances of selecting the correct response.

- Stay Calm and Focused: Test anxiety can affect performance. Practice deep breathing and stay focused to remain calm during the test.

By following these strategies, you can boost your confidence and improve your performance, ensuring that you are well-prepared for the certification assessment.

How Lesson 9 Impacts Certification

Mastering the material in this section is essential for achieving certification in safety practices related to the industry. The concepts covered are not only foundational but also directly relevant to the final assessment, influencing both the test results and the practical application of knowledge. Understanding the core principles ensures that individuals can demonstrate the competence required for certification and apply these practices effectively in real-world scenarios.

Lesson 9 provides valuable insights into crucial procedures, highlighting areas where knowledge and attention to detail can prevent mishaps and ensure the health and safety of everyone involved. The skills gained here contribute significantly to one’s ability to meet certification standards, making it a vital step in the learning journey.

In summary, mastering the concepts taught in this section enhances your preparedness for the assessment and solidifies your qualifications, ensuring that you meet the necessary requirements for certification in your field.