Ensuring a secure environment while working with vehicles is crucial for both professionals and customers. Various practices and guidelines are put in place to minimize risks and promote well-being in repair shops and other related locations. Understanding the fundamental principles of these safety standards is vital for anyone in the industry, as it directly impacts the overall success and smooth operation of any maintenance task.

To excel in this area, individuals must familiarize themselves with key protocols, potential hazards, and the proper use of protective measures. There are specific tests designed to assess one’s proficiency in these areas, and preparing for such assessments can make a significant difference in improving knowledge and reducing workplace injuries. The path to mastering these concepts involves studying a range of topics that address the diverse risks faced on a daily basis in the field.

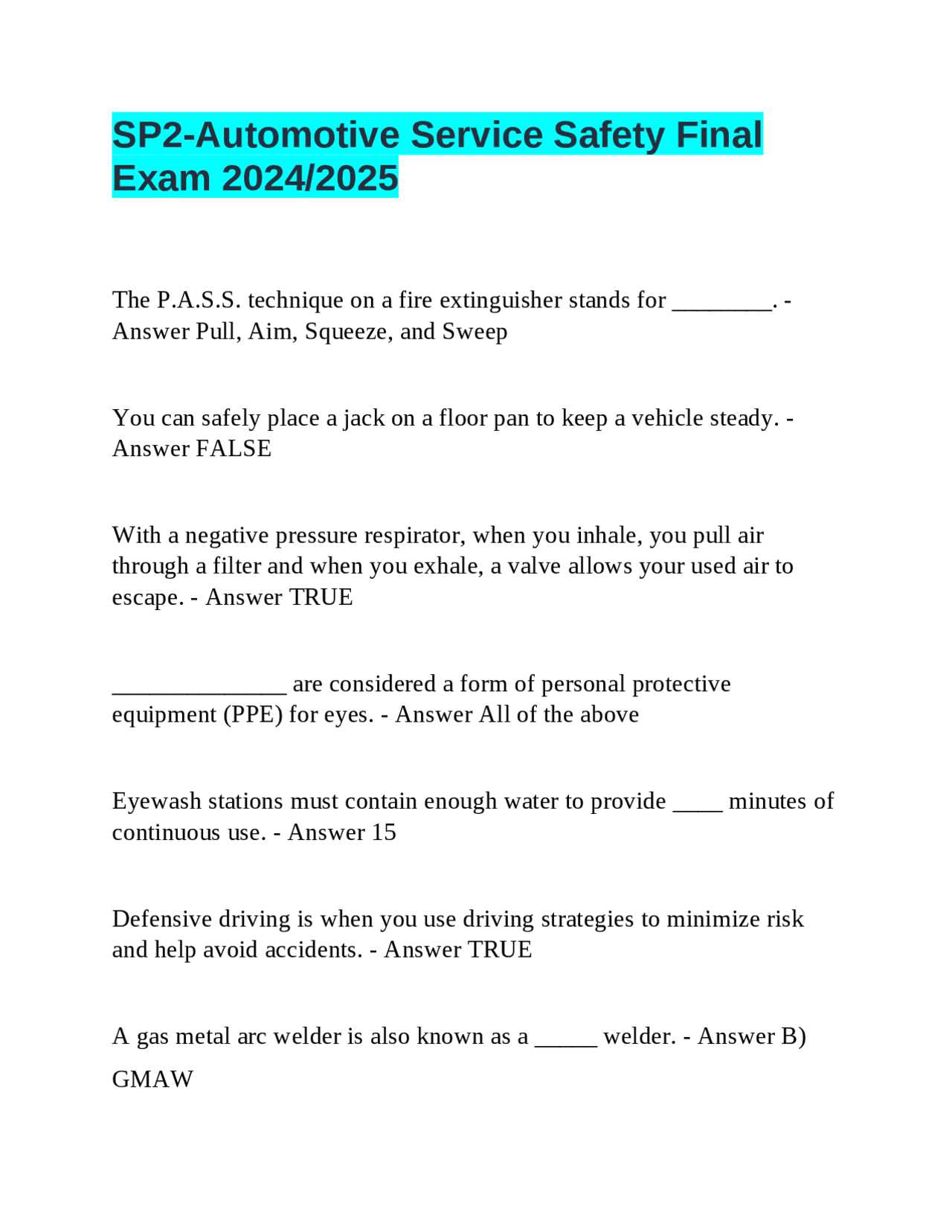

Automotive Service Safety Final Exam Overview

In any industry that involves vehicle maintenance, understanding the proper guidelines and protocols is essential for minimizing risks and ensuring the well-being of everyone involved. The process of becoming proficient in these standards involves completing a series of assessments that test knowledge and readiness to handle various situations. These evaluations are designed to confirm that individuals are fully prepared to follow established practices that promote a secure working environment.

Key Areas of Focus

The assessment covers a wide range of topics, from general workplace hazards to specific tools and machinery safety. It emphasizes the importance of adhering to guidelines that protect both technicians and customers. The core of these evaluations lies in a deep understanding of common risks and how to mitigate them through responsible actions and the use of proper equipment. Familiarity with emergency procedures, proper tool handling, and hazard recognition are fundamental components that candidates must master to demonstrate their competency.

Preparing for the Assessment

To succeed, individuals must dedicate time to studying the relevant materials, including manuals, industry best practices, and safety regulations. Regular practice and mock assessments can help reinforce key concepts and improve test-taking strategies. A strong understanding of each topic ensures that the individual can quickly apply the knowledge in real-world scenarios, reducing the chance of accidents or mistakes. The more thorough the preparation, the higher the likelihood of achieving a passing result and confidently implementing these safety standards in a professional setting.

Key Concepts in Automotive Safety

Understanding the essential principles of risk management is critical in any environment that involves vehicle maintenance and repair. These fundamental concepts help create a structured approach to ensuring well-being and preventing accidents. By familiarizing oneself with these key ideas, individuals are equipped to recognize hazards, adopt preventative measures, and respond effectively in emergency situations.

Hazard Recognition and Risk Assessment

Identifying potential dangers is the first step in creating a secure workspace. This includes being aware of common risks, such as slippery surfaces, electrical hazards, and exposure to toxic substances. Recognizing these threats allows workers to implement appropriate precautions, such as proper ventilation, signage, and the use of protective gear. Risk assessment involves evaluating the likelihood and severity of various hazards, enabling workers to prioritize actions that mitigate the most dangerous scenarios.

Proper Equipment Use and Maintenance

The correct use of tools and machinery is essential to avoid injuries. Ensuring that equipment is well-maintained and operating as intended reduces the chances of malfunction or accidents. Regular inspections and following manufacturer guidelines for tool usage can prevent mishaps and enhance overall efficiency. Training workers to handle tools responsibly, along with reinforcing the importance of regular equipment checks, ensures that everyone in the workspace remains safe and productive.

Understanding SP2 Certification Requirements

Obtaining certification in this field involves meeting specific standards and demonstrating competence in various essential aspects of risk management and equipment handling. The certification process is designed to ensure that individuals possess the necessary knowledge to maintain a secure environment while working with vehicles. It provides recognition for those who have completed required training and proven their ability to apply safety protocols effectively.

Prerequisites for Certification

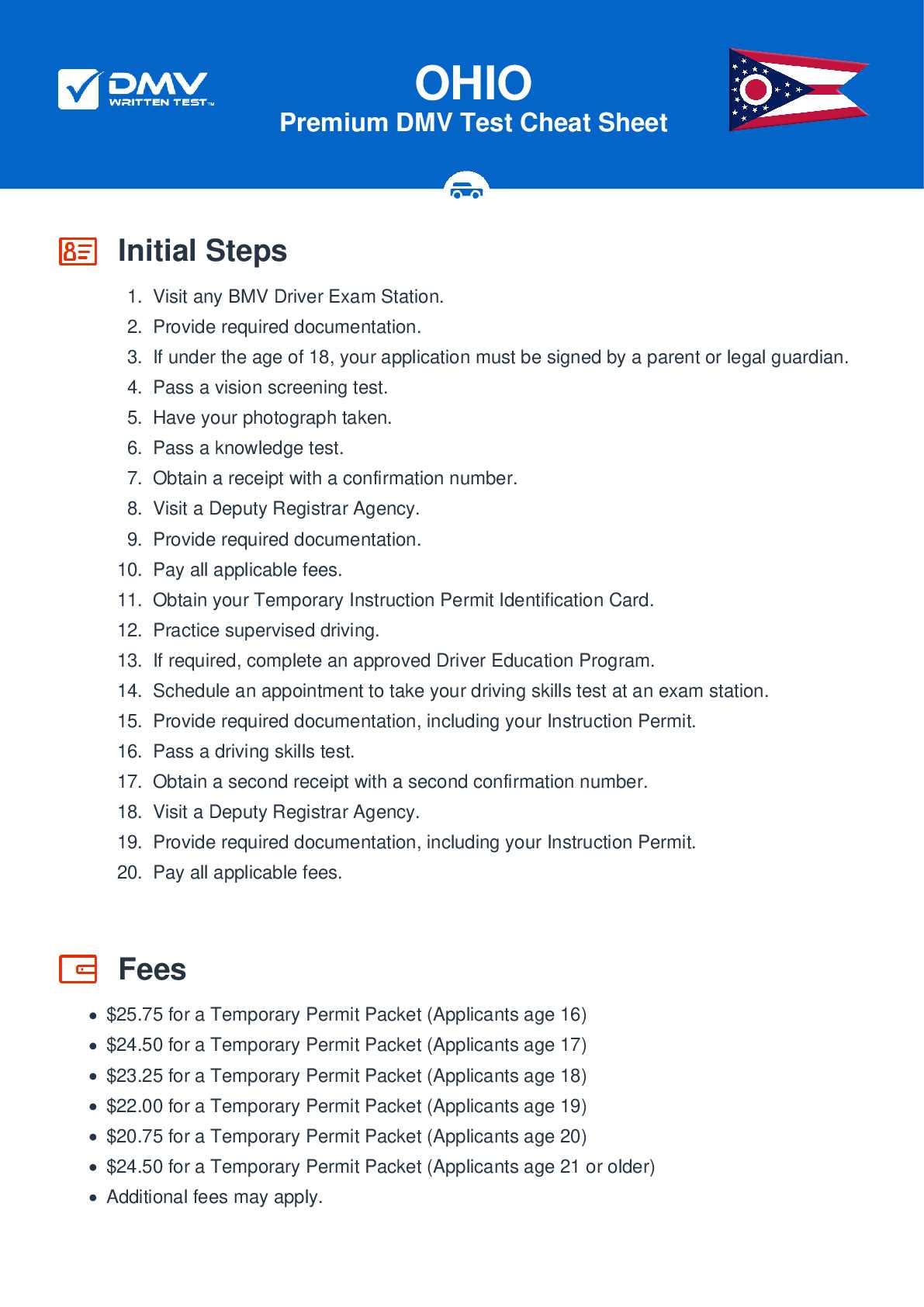

Before attempting certification, candidates must complete a series of courses and training sessions focused on hazard prevention, proper tool usage, and emergency protocols. The training is designed to cover both theoretical knowledge and practical skills. A strong understanding of industry guidelines, along with hands-on experience, is crucial to successfully meeting the requirements. Additionally, candidates must demonstrate the ability to respond quickly and appropriately to various emergency situations.

Key Areas Tested for Certification

The assessment focuses on several critical areas, such as identifying potential hazards, implementing protective measures, and following established safety protocols. Understanding the correct procedures for handling chemicals, machinery, and heavy equipment is essential. Maintaining a clean and organized workspace also plays a vital role in reducing risks. Certification requires a thorough grasp of these concepts, ensuring that individuals are fully prepared to work in a professional setting with minimal risk.

Importance of Safety in Auto Repairs

Ensuring a secure working environment in vehicle maintenance is essential for the well-being of both technicians and customers. A professional repair shop should prioritize the protection of workers from potential hazards that arise from the tools, equipment, and materials used daily. Recognizing and mitigating risks is crucial not only for preventing accidents but also for maintaining a smooth, efficient operation.

- Prevents Workplace Injuries: Implementing protective measures significantly reduces the likelihood of accidents, such as cuts, burns, and falls.

- Enhances Operational Efficiency: Safe work practices contribute to a more organized and productive environment, minimizing downtime caused by accidents.

- Builds Trust with Clients: Customers feel confident knowing that their vehicle is being worked on in a secure environment, which fosters positive relationships and repeat business.

Adhering to safety protocols not only reduces risks but also improves overall performance. Technicians who work in a secure environment are less likely to make errors, leading to higher-quality work and more satisfied customers. Safety measures go beyond physical protection, impacting the overall workflow and success of a repair shop.

Common Exam Topics for SP2

When preparing for the certification assessment, it’s important to focus on the key areas that are commonly covered. These topics not only assess a candidate’s ability to follow proper guidelines but also test their practical knowledge in identifying and managing risks. Understanding these core subjects will help ensure a comprehensive grasp of the requirements, allowing individuals to effectively demonstrate their competence in a professional setting.

Risk Management and Hazard Prevention

One of the most critical areas is understanding how to recognize potential dangers in the work environment. This includes being familiar with common hazards such as electrical risks, exposure to chemicals, and potential injuries from equipment. The ability to assess these risks and take the necessary precautions is essential for minimizing accidents. Effective hazard identification and risk management are key components of the assessment process.

Proper Equipment Handling and Maintenance

The correct use and upkeep of tools and machinery are also important topics that often appear in the evaluation. This includes knowing the proper techniques for using various equipment, as well as understanding the safety measures that should be followed. Regular maintenance and inspection of tools ensure they function safely and efficiently. Demonstrating knowledge of these practices is crucial for passing the certification and maintaining a secure working environment.

Preparing for the Safety Final Exam

Proper preparation for the certification assessment requires a structured approach, focusing on the key principles and procedures that ensure a secure work environment. Gaining a deep understanding of the core concepts, coupled with practical experience, is essential for success. Effective study techniques, along with utilizing the right resources, will help reinforce critical knowledge and boost confidence when it’s time to take the assessment.

The following table outlines some of the essential areas to focus on during your preparation:

| Topic | Description | Recommended Resources |

|---|---|---|

| Hazard Identification | Recognizing potential dangers in the workplace and understanding how to address them. | Safety manuals, online courses, and risk management guides. |

| Proper Tool Usage | Learning the correct handling techniques for different equipment and tools to avoid accidents. | Manufacturer manuals, hands-on practice, instructional videos. |

| Emergency Procedures | Understanding how to respond to various emergency situations efficiently and calmly. | Emergency response drills, safety workshops, guidelines from regulatory bodies. |

| Personal Protective Equipment (PPE) | Familiarizing yourself with the proper protective gear required for different tasks. | Workshops, PPE training sessions, safety regulations documents. |

By focusing on these key areas and utilizing the appropriate resources, you will be well-equipped to tackle the certification and demonstrate your knowledge effectively. Consistent study and hands-on experience are essential for mastering the necessary skills and passing the assessment with confidence.

Best Study Resources for SP2 Test

To succeed in the certification assessment, it’s important to utilize a variety of study materials that cover the essential concepts and practical skills. The right resources can provide a comprehensive understanding of the necessary safety procedures, risk management strategies, and equipment handling techniques. Whether you’re a visual learner, prefer hands-on practice, or like to read in-depth materials, there are plenty of options to help you prepare effectively.

- Online Training Courses: Many platforms offer detailed courses that cover all the critical topics. These courses often include interactive modules and quizzes to test your understanding.

- Safety Guidelines and Manuals: Reviewing official safety manuals and guidelines from trusted industry sources is a great way to ensure you are familiar with the standards and procedures required for certification.

- Practice Tests: Taking practice tests is one of the best ways to assess your knowledge and identify areas for improvement. These mock exams simulate the real assessment environment.

- Instructional Videos: Visual learners will benefit from video tutorials that demonstrate safety protocols, equipment use, and emergency procedures.

- Workshops and Hands-On Training: Attending workshops and practicing in a controlled environment provides the opportunity to apply concepts and receive direct feedback.

By combining these resources, you can enhance your understanding and ensure you are fully prepared for the certification process. A well-rounded approach to studying will allow you to retain information more effectively and approach the assessment with confidence.

Frequently Asked Questions on SP2 Exam

Preparing for the certification assessment can raise several questions. It’s common for individuals to have doubts about the process, requirements, and key areas to focus on. This section aims to address the most frequently asked questions to help candidates feel more confident and well-informed as they approach the evaluation.

- What topics are covered in the assessment? The test typically covers risk management, hazard identification, proper equipment handling, and emergency procedures. It’s important to have a comprehensive understanding of these areas to ensure success.

- How can I prepare for the assessment? A combination of online courses, practice tests, safety manuals, and hands-on training is the most effective way to prepare. Focus on key concepts and practical skills.

- Is there a time limit for the test? Yes, most assessments have a time limit. It’s important to manage your time wisely during the test to ensure you can complete all sections.

- Can I retake the assessment if I fail? Yes, in most cases, you can retake the certification test. However, there may be a waiting period, and you will need to complete additional review before reattempting.

- Are there any prerequisites for taking the assessment? While there are no formal prerequisites, completing training courses and gaining hands-on experience in a relevant field is highly recommended to ensure a thorough understanding of the material.

- What is the passing score? The passing score varies depending on the certification, but most require a score of at least 80% to pass. It’s important to thoroughly review all material to ensure you meet this standard.

By addressing these common concerns, candidates can approach the assessment with greater clarity and preparedness, increasing their chances of success.

Safety Protocols in Automotive Shops

In any workshop or repair facility, following proper protocols is essential to ensuring the health and well-being of everyone involved. From mechanics to visitors, all individuals must be aware of the procedures designed to minimize risks and prevent accidents. Adhering to these standards not only helps maintain a safe working environment but also ensures that all tasks are completed efficiently and without harm.

Proper Equipment Handling

One of the fundamental aspects of safety is the correct usage and maintenance of tools and machinery. Workers should be well-trained in handling equipment such as lifts, power tools, and diagnostic machines. Regular inspection and maintenance of these tools are also vital to ensure they are functioning properly and do not pose any risk to the user. Personal protective equipment (PPE), such as gloves and goggles, should always be worn when handling dangerous equipment to minimize exposure to hazards.

Emergency Procedures and First Aid

Preparedness for emergencies is another crucial protocol. Every shop should have clear and easily accessible emergency procedures, including evacuation routes and first aid kits. All personnel should be trained in basic first aid, CPR, and how to respond to common injuries, such as burns or electrical shocks. In addition, emergency contacts should be posted in visible areas so that help can be summoned immediately if needed. Regular drills should also be conducted to ensure everyone is familiar with these protocols in case of a real emergency.

How to Approach the SP2 Test

Approaching any certification assessment requires a structured and methodical approach. To succeed in the certification process, candidates must prepare not only by understanding key concepts but also by practicing their skills and managing their time efficiently. With a clear plan and focused mindset, you can increase your chances of passing the test on your first attempt.

Understand the Key Topics

Start by familiarizing yourself with the key subjects covered in the assessment. Review the guidelines, manuals, and recommended materials to ensure you understand the core principles. Focus on areas such as risk management, proper tool handling, and emergency procedures. Make a study plan and allocate time to review each topic thoroughly.

Practice with Mock Tests

Taking practice tests is one of the most effective ways to prepare. These mock assessments help you become familiar with the test format and identify areas where you may need further study. By simulating the real testing environment, you can build confidence and reduce any anxiety you may feel on the day of the assessment.

Remember to pace yourself during the test, read each question carefully, and take breaks if needed. A calm and focused approach will allow you to perform at your best.

Critical Safety Procedures in Auto Service

In any repair environment, ensuring the well-being of workers and preventing accidents are of utmost importance. Adhering to essential safety protocols not only protects individuals but also ensures efficient and high-quality work. By implementing the right procedures, technicians can avoid common hazards, reduce the risk of injury, and maintain a smooth workflow.

Below are some of the critical safety procedures that should be followed in any repair facility:

| Safety Procedure | Description |

|---|---|

| Proper Tool Handling | Ensure all tools are used according to the manufacturer’s instructions. Regularly inspect equipment for damage and maintain it properly. |

| Personal Protective Equipment (PPE) | Always wear appropriate PPE such as gloves, goggles, and ear protection. This helps prevent exposure to harmful substances and reduces injury risk. |

| Hazard Identification | Identify potential risks in the workspace, such as flammable materials or electrical hazards, and take steps to mitigate them. |

| Emergency Response Plan | Ensure all workers are trained on emergency procedures, including first aid, CPR, and how to react in case of fire or injury. |

| Proper Ventilation | Ensure workspaces are properly ventilated to avoid inhaling harmful fumes from chemicals, exhaust systems, or other sources. |

| Electrical Safety | Always disconnect power sources before working on electrical systems. Use insulated tools and follow strict protocols when handling electrical components. |

By following these critical procedures, technicians can significantly reduce the risk of injury and create a safer working environment for everyone involved. Regular training and adherence to these practices are essential to maintaining a safe and efficient workspace.

Top Mistakes to Avoid on SP2

While preparing for any assessment, avoiding common pitfalls is key to ensuring success. Certain mistakes, if overlooked, can have a significant impact on your performance. Being aware of these missteps and taking proactive measures can help you avoid unnecessary errors and boost your confidence when facing the test.

Rushing Through Questions

One of the most frequent mistakes is rushing through the questions without fully understanding them. It’s tempting to move quickly, but this approach often leads to misinterpretation. Take the time to read each question carefully and consider all options before choosing your answer. A thoughtful and deliberate approach will increase your chances of success.

Ignoring Key Instructions

Every assessment comes with specific instructions, and failing to follow them can hurt your performance. Whether it’s the format for answering questions or guidelines for selecting multiple options, it’s crucial to pay attention to every detail. Ignoring these instructions could lead to unnecessary mistakes or disqualification of your answers.

By staying calm, focused, and mindful of these common mistakes, you can approach the test with confidence and achieve a successful outcome. Proper preparation and careful attention to the process will ensure that you are well-equipped to handle any challenges that come your way.

Exam Techniques for Automotive Safety

When preparing for an assessment focused on workplace protocols and risk management, employing the right techniques can make a significant difference in your performance. Effective strategies help not only in retaining essential information but also in ensuring that you approach the test with clarity and confidence. Whether you are dealing with practical scenarios or theoretical questions, the following techniques can enhance your success rate.

Start by reviewing all the material thoroughly before the test. Focus on key concepts, important regulations, and critical steps for hazard prevention. Understanding these core ideas will provide a solid foundation for answering any questions that might arise. Once you’re familiar with the material, practice applying it to real-life situations, as many assessments test your ability to think critically under pressure.

During the test, stay calm and focused. Prioritize answering questions you are most confident about, leaving the more challenging ones for later. Carefully read each question and all possible answers, eliminating obviously incorrect options first. Time management is also crucial, so make sure to pace yourself and avoid spending too much time on any single question.

By combining careful preparation with strategic execution during the test, you will increase your chances of performing well and successfully demonstrating your knowledge of important workplace protocols.

What to Do After Passing the SP2

Successfully completing the assessment is a significant achievement, but it’s just one step in the journey. After passing, it’s essential to reflect on the accomplishment and take the right steps to maximize its value. Whether you’re entering a new role or seeking to enhance your existing skills, the next actions you take will shape your career trajectory and ongoing development.

First, ensure you receive your certification or completion acknowledgment. This official documentation is often required by employers as proof of your knowledge in key safety and operational protocols. Keep a copy for your records and share it with relevant parties, such as your employer or industry regulators, if necessary.

Once certified, it’s important to stay updated on the latest regulations and best practices. While you’ve learned foundational principles, the field constantly evolves. Regularly review new training materials, attend refresher courses, or engage in related workshops to stay informed and continue building your expertise.

Additionally, consider applying the knowledge you’ve gained in practical environments. This not only reinforces what you’ve learned but also helps you gain hands-on experience, which is often crucial for long-term success in any role. By actively applying your skills, you demonstrate competence and commitment to safety standards, which will make you a valuable asset in any workplace.

Understanding Hazards in Auto Service

In any hands-on work environment, especially those involving mechanical systems, understanding potential risks is crucial. The workplace is filled with a variety of hazards that can affect both employees and customers. Being aware of these dangers and knowing how to mitigate them ensures that everyone stays protected while the work is being performed.

Common hazards in this type of setting often stem from equipment, chemicals, and working conditions. It’s vital to recognize these threats early and adopt the appropriate precautions to prevent accidents. Below are some common types of hazards to be aware of:

- Physical Hazards: Moving machinery, heavy equipment, and tools can cause physical injuries if not handled properly.

- Chemical Hazards: Exposure to oils, fuels, solvents, and other chemicals can lead to health issues like skin irritation, respiratory problems, or long-term illness.

- Electrical Hazards: Working with electrical systems or faulty wiring can result in shocks, burns, or even fires if proper precautions aren’t followed.

- Fire Hazards: Flammable liquids and gases, combined with improper storage or handling, can lead to catastrophic fires.

By identifying and addressing these hazards, workers can significantly reduce the likelihood of accidents and create a safer working environment. Proper training, safety protocols, and personal protective equipment are key components in managing these risks effectively.

Essential Tools for Auto Safety

Working in environments that involve mechanical work requires more than just skill and knowledge–it also demands the right tools to ensure the protection of everyone involved. Tools designed for safety purposes not only help in performing tasks more efficiently but also prevent potential risks and injuries. Having the right equipment on hand can make a significant difference in maintaining a secure workspace.

Below are some essential tools that help mitigate hazards and ensure proper protective measures:

- Personal Protective Equipment (PPE): Items like gloves, goggles, hearing protection, and steel-toed boots are vital in safeguarding workers from injuries.

- Fire Extinguisher: A must-have in any environment where flammable materials are handled, a fire extinguisher can quickly prevent a small incident from escalating.

- First Aid Kits: Quick access to a well-stocked first aid kit is crucial for addressing minor injuries before they become more serious.

- Proper Ventilation Systems: Ensuring that the workspace is well-ventilated, especially when working with chemicals or gases, reduces the risk of respiratory issues.

- Lockout/Tagout Devices: These tools help prevent accidents when dealing with heavy machinery by ensuring that equipment is properly shut off and cannot be restarted unintentionally.

Investing in these tools and ensuring they are well-maintained is a proactive way to foster a safer working environment. Proper training on their use and the importance of regular safety checks can significantly reduce the likelihood of accidents.

Why Safety Matters in Car Maintenance

When it comes to maintaining vehicles, ensuring that proper precautions are taken is crucial not only for the well-being of individuals working on the cars but also for the integrity of the vehicles themselves. A single misstep in handling equipment or performing a repair can lead to significant accidents, damage, or even long-term vehicle malfunction. By prioritizing correct practices and adhering to established guidelines, risks can be minimized, creating a safer environment for both workers and customers.

Accidents in vehicle maintenance environments are often preventable with the right precautions. Whether dealing with lifting heavy components, using power tools, or handling potentially hazardous fluids, taking the time to understand and follow the correct procedures reduces the chances of injury. Workers who are trained in the proper handling of tools and equipment are less likely to make mistakes that could lead to accidents or unnecessary damage.

Additionally, focusing on safe practices helps ensure that vehicles are not only repaired effectively but also operate safely once they leave the workshop. Improperly handled repairs can lead to undetected issues that compromise the vehicle’s performance or lead to further problems down the road. This makes the emphasis on safety doubly important–both to protect the individual performing the work and to ensure that the customer’s vehicle is in top condition.

In the long run, maintaining a culture of safety helps build trust, not just within the team but also with clients who rely on the quality of the work being done. It is not just about avoiding accidents, but also about providing peace of mind that the work is done correctly and responsibly.

Staying Up-to-Date with Safety Standards

Maintaining a thorough understanding of current protocols and regulations is vital for anyone involved in vehicle repair and maintenance. As the industry evolves, so too do the guidelines and standards that govern safe practices. Staying informed about new developments, regulatory updates, and best practices ensures that both professionals and customers are protected from potential risks. This knowledge is not only crucial for preventing accidents but also for ensuring that all work is completed to the highest standards of quality.

Why Continuous Education is Essential

As regulations change and new safety technology becomes available, ongoing training and education are key to staying compliant. Professionals who commit to regularly updating their knowledge can avoid the pitfalls of outdated methods that could compromise both their well-being and the quality of their work. By attending seminars, enrolling in refresher courses, and participating in industry forums, individuals can stay ahead of the curve and ensure they are always working within the latest guidelines.

How to Stay Informed

There are several practical ways to stay informed about evolving standards and practices. These include:

- Regularly reading industry publications and safety guidelines from authoritative bodies.

- Participating in professional organizations and attending conferences.

- Engaging in online courses or certification programs offered by reputable institutions.

- Networking with other professionals to exchange knowledge and share insights about new trends and requirements.

By making continuous learning a priority, individuals can ensure they are always operating at the highest level of professionalism and are equipped to handle new challenges safely and effectively.