In today’s workplace, understanding safety protocols and proper handling of hazardous materials is crucial. To ensure the health and well-being of employees, comprehensive training is required. This certification is essential for those working with chemicals, hazardous substances, and other dangerous materials. By mastering key concepts and safety procedures, individuals can reduce the risk of accidents and contribute to a safer working environment.

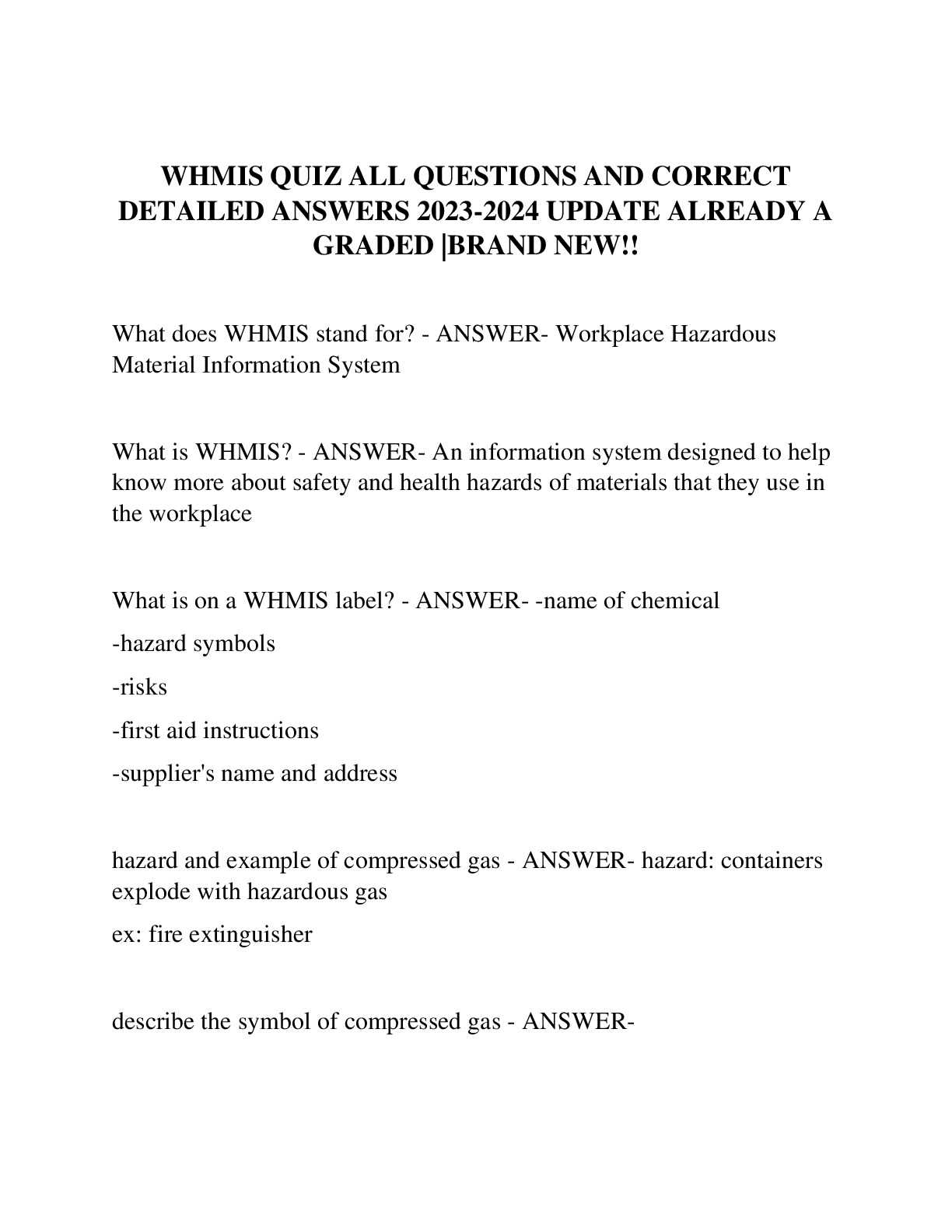

As part of the certification process, individuals must demonstrate their knowledge of safety labels, hazard symbols, and safe handling practices. The preparation involves studying various materials, including guidelines, safety data sheets, and regulations. Being well-versed in these areas is essential to pass the assessment and meet the standards set by workplace safety authorities.

Understanding the key principles and applying them correctly can make a significant difference in passing the certification. It requires focus, practical knowledge, and the ability to recognize potential hazards before they cause harm. The following guide will help you navigate the preparation process and achieve the necessary qualifications for workplace safety.

Workplace Safety Certification and Key Concepts

Gaining a thorough understanding of workplace safety and handling hazardous materials is vital for those working in environments where chemicals and dangerous substances are present. To pass the required certification, candidates must demonstrate their knowledge of safety protocols, symbols, and proper handling practices. This section will highlight the core ideas and concepts essential for achieving success in the certification process.

Core Knowledge Areas for Certification

- Identification of Hazardous Materials: Understanding the types of substances that pose risks and their effects.

- Label Interpretation: Recognizing and correctly interpreting safety labels, including hazard symbols.

- Safety Data Sheets: Familiarity with key information on material safety data sheets, such as risks, handling procedures, and emergency actions.

- Risk Assessment: Ability to assess potential hazards in the workplace and apply appropriate safety measures.

- Personal Protective Equipment (PPE): Knowledge of necessary equipment to safely handle materials.

Commonly Tested Concepts

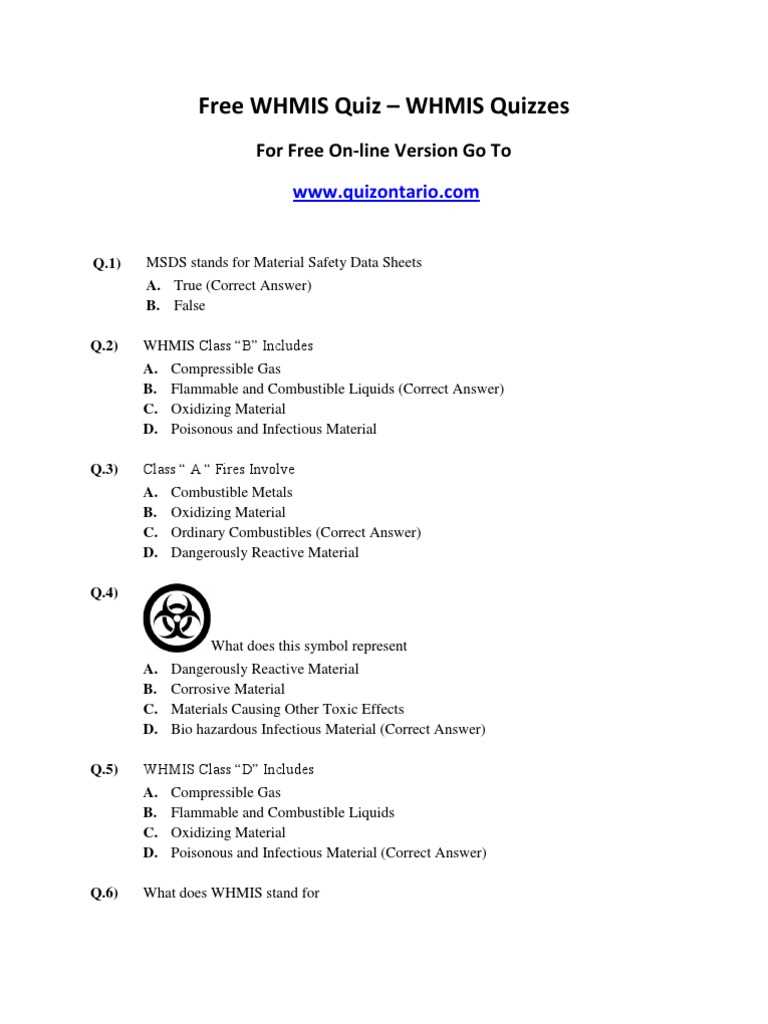

- Hazard Classification: Understanding the different categories of hazards, such as physical, health, and environmental risks.

- Labeling Systems: Recognition of standardized labels that provide critical safety information.

- Workplace Emergency Procedures: Knowledge of emergency response actions, including first aid, evacuation, and containment of hazardous materials.

- Safety Compliance: Understanding regulations and legal requirements that govern safety practices in various industries.

Mastering these fundamental concepts will not only help individuals pass the required assessment but also ensure a safe and productive working environment. Practical knowledge of safety procedures, along with a clear understanding of hazard symbols and classification, is essential for minimizing risks in the workplace.

Understanding Workplace Safety Certification Structure

To successfully obtain certification for working with hazardous materials, individuals must first become familiar with the structure and requirements of the assessment process. The certification is designed to test a wide range of knowledge related to safety practices, material handling, and hazard recognition. Understanding the format of the test is crucial to approach it with confidence and increase your chances of success.

Assessment Format and Components

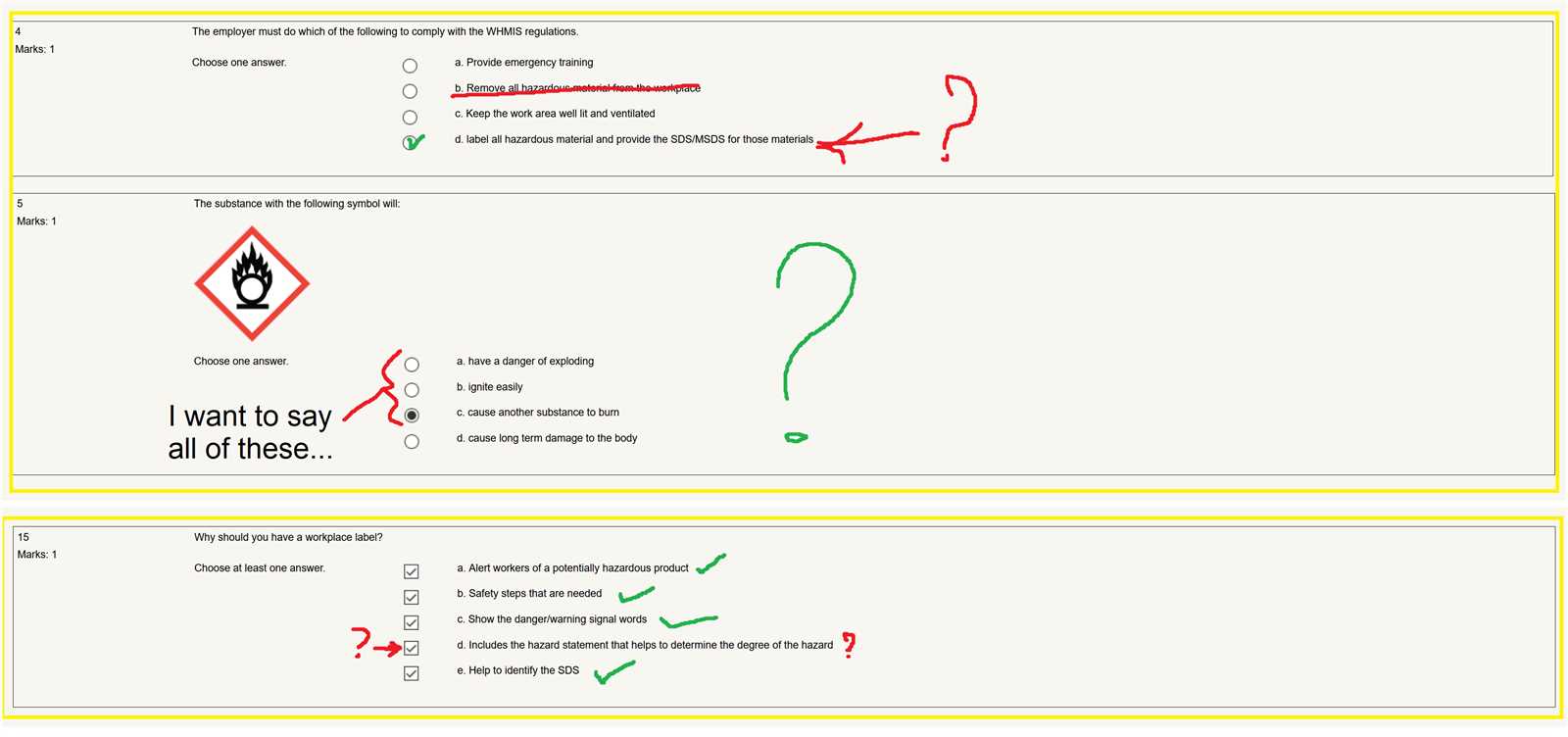

- Multiple Choice Questions: These questions assess knowledge of key safety concepts, regulations, and hazard identification. Candidates will be asked to select the most accurate answer from a set of options.

- Scenario-Based Questions: In these questions, you will be presented with hypothetical situations requiring you to apply safety procedures and make appropriate decisions based on the information provided.

- Label and Symbol Identification: Candidates will be asked to identify and interpret various safety labels and symbols that represent potential hazards in the workplace.

Time Limits and Passing Criteria

The certification process usually has a time limit, with most assessments allowing a set number of minutes to answer all questions. To pass, candidates must meet a minimum score threshold, which typically requires a strong understanding of safety protocols, regulations, and hazard prevention methods. Focusing on key areas such as material identification, safety procedures, and risk management will help ensure success.

By becoming familiar with the structure and expectations of the assessment, individuals can better prepare and approach the certification process with a clear strategy, ensuring they meet all necessary safety standards and pass with confidence.

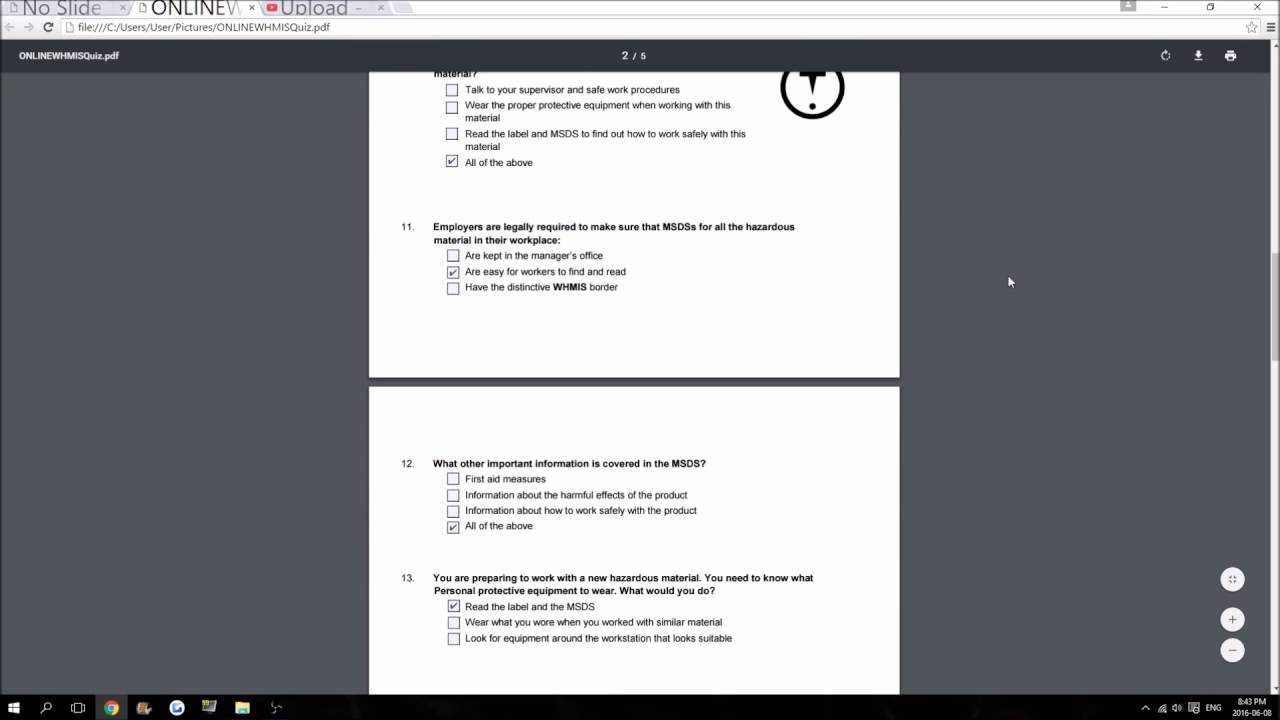

Commonly Asked Workplace Safety Questions

During the certification process, candidates are often faced with questions that test their understanding of workplace safety, material handling, and hazard identification. These questions are designed to evaluate how well individuals can apply safety principles to real-world situations. Being prepared for the most common types of questions will help you approach the assessment with greater confidence and success.

Some questions frequently focus on the identification of hazardous materials, the correct use of personal protective equipment (PPE), and the interpretation of safety symbols and labels. Others may ask about emergency procedures, such as what to do in case of a chemical spill or how to properly store dangerous substances. Understanding these topics in detail is key to passing the certification.

To help you prepare, it’s important to review common topics like hazard classifications, the proper handling and storage of chemicals, and the identification of potential risks in various work environments. Additionally, being familiar with safety data sheets and emergency response protocols will increase your ability to answer questions accurately.

Preparation Tips for Workplace Safety Success

Proper preparation is key to succeeding in any safety certification, especially when it involves handling hazardous materials and understanding workplace safety protocols. To achieve the required certification, it’s essential to not only review important topics but also to practice applying the knowledge in real-world scenarios. These tips will help you focus your efforts and improve your chances of success.

Study Strategies for Effective Learning

- Review Key Concepts: Focus on understanding hazard classifications, safety labels, and handling procedures for different substances.

- Use Practice Questions: Test your knowledge with sample questions to familiarize yourself with the types of questions you may face during the assessment.

- Create Study Notes: Summarize essential safety procedures, symbols, and regulations in your own words to reinforce your understanding.

- Join Study Groups: Collaborating with others can help reinforce concepts through discussion and shared knowledge.

Familiarizing Yourself with Safety Materials

- Understand Safety Data Sheets: Review sample sheets to learn how to identify key information about hazardous materials, including risks and first-aid procedures.

- Learn the Labeling System: Be sure to recognize different safety symbols and what they signify in terms of risks and protective measures.

- Know Emergency Procedures: Review proper actions in the event of an accident or chemical spill, including the use of personal protective equipment and emergency response protocols.

By following these preparation tips, you can approach the certification process with a solid understanding of safety protocols and hazard prevention, ensuring your success and the safety of those around you in the workplace.

Study Materials for Workplace Safety Certification

Preparing for a workplace safety certification requires access to high-quality study materials that cover all the essential topics, from hazard recognition to emergency response. By reviewing the right resources, candidates can enhance their understanding of safety procedures and material handling. The following study materials will provide a solid foundation for anyone looking to achieve success in their certification process.

Essential Resources for Effective Preparation

- Safety Data Sheets (SDS): These documents provide detailed information on the handling, storage, and risks associated with hazardous materials. Familiarizing yourself with these will ensure you can identify key safety information.

- Regulatory Guidelines: Understanding the local and national regulations that govern workplace safety is crucial. Review the relevant legal standards to ensure compliance.

- Practice Tests: Taking practice tests will help you become familiar with the format of the assessment and identify areas where additional review is needed.

- Safety Label Guides: Study guides that explain the different symbols and labels used in the workplace can help you understand potential risks quickly.

Recommended Study Materials Table

| Material Type | Description | Purpose |

|---|---|---|

| Safety Data Sheets | Documents detailing risks, handling procedures, and emergency actions for hazardous materials. | Learn how to safely handle materials and respond to emergencies. |

| Regulatory Guidelines | Government-issued documents outlining safety laws and best practices. | Ensure compliance with workplace safety standards and regulations. |

| Practice Tests | Sample questions designed to test your knowledge of safety procedures. | Prepare for the assessment by simulating the test environment. |

| Safety Label Guides | Visual resources explaining the meaning of various hazard symbols. | Quickly identify risks and follow correct safety protocols in the workplace. |

By utilizing these study materials, you can ensure that you are fully prepared for the certification process. The right resources will help you grasp the key concepts, build your confidence, and ultimately succeed in maintaining a safe working environment.

How to Interpret Safety Labels

Understanding safety labels is a crucial aspect of ensuring safe handling and storage of hazardous materials in the workplace. These labels provide essential information about potential risks, required precautions, and emergency response actions. Being able to quickly and accurately interpret these labels helps protect both workers and the environment from harm. This section explains how to effectively read and understand the key elements found on safety labels.

Key Components of a Safety Label

- Signal Words: These indicate the level of hazard. “Danger” is used for more severe risks, while “Warning” is for less severe, but still significant, hazards.

- Hazard Pictograms: Symbols that represent specific types of hazards. These icons help workers quickly identify the nature of the risk, such as toxicity, flammability, or corrosiveness.

- Precautionary Statements: Instructions on how to handle, store, and dispose of the material safely, along with protective equipment recommendations.

- First Aid Measures: Information on how to respond in case of exposure, including specific steps for medical attention in case of accidental contact or ingestion.

How to Read a Safety Label Effectively

- Identify the Signal Word: Start by identifying the signal word to understand the urgency of the hazard.

- Examine the Pictograms: Look for the hazard symbols to gain a quick understanding of the type of risk associated with the material.

- Read the Precautionary Statements: Follow the instructions on how to safely handle and use the material, including necessary precautions and recommended personal protective equipment (PPE).

- Review First Aid Measures: Be aware of the proper response actions in case of an emergency, such as skin contact, inhalation, or ingestion of the material.

By becoming familiar with these key components, workers can enhance their safety awareness and make informed decisions when working with hazardous substances. Understanding safety labels ensures that risks are minimized, and proper safety protocols are followed in the workplace.

Workplace Hazard Symbols Explained

Hazard symbols are critical tools used in the workplace to communicate potential risks associated with materials or activities. These symbols provide a clear visual representation of the type of hazard present, enabling workers to quickly assess the risks and take appropriate precautions. Understanding these symbols is essential for maintaining a safe work environment and ensuring that necessary protective measures are followed.

Common Hazard Symbols and Their Meanings

- Flame: Indicates that the substance is flammable or self-heating. This symbol is used for materials that can catch fire easily.

- Exclamation Mark: Represents a less severe hazard, such as skin or eye irritation, or a respiratory issue. This symbol indicates a general irritant.

- Skull and Crossbones: Signals that the material is toxic or fatal when inhaled, ingested, or absorbed through the skin.

- Corrosion: Used for materials that can cause severe damage to skin, eyes, or other materials upon contact.

- Health Hazard: Indicates substances that may cause serious health effects, such as cancer, respiratory issues, or reproductive harm.

How to Interpret Hazard Symbols in the Workplace

Each hazard symbol is designed to convey essential information about a specific risk, but it is crucial to also consider the context in which the symbol is used. Workers should always refer to safety data sheets and precautionary measures to fully understand the necessary actions for safe handling. Whether dealing with toxic chemicals, corrosive substances, or flammable materials, proper training and awareness of these symbols can significantly reduce the risk of accidents.

By understanding the various hazard symbols, workers can enhance their ability to identify risks in their environment and follow appropriate safety protocols to minimize harm and ensure a safer workplace for everyone.

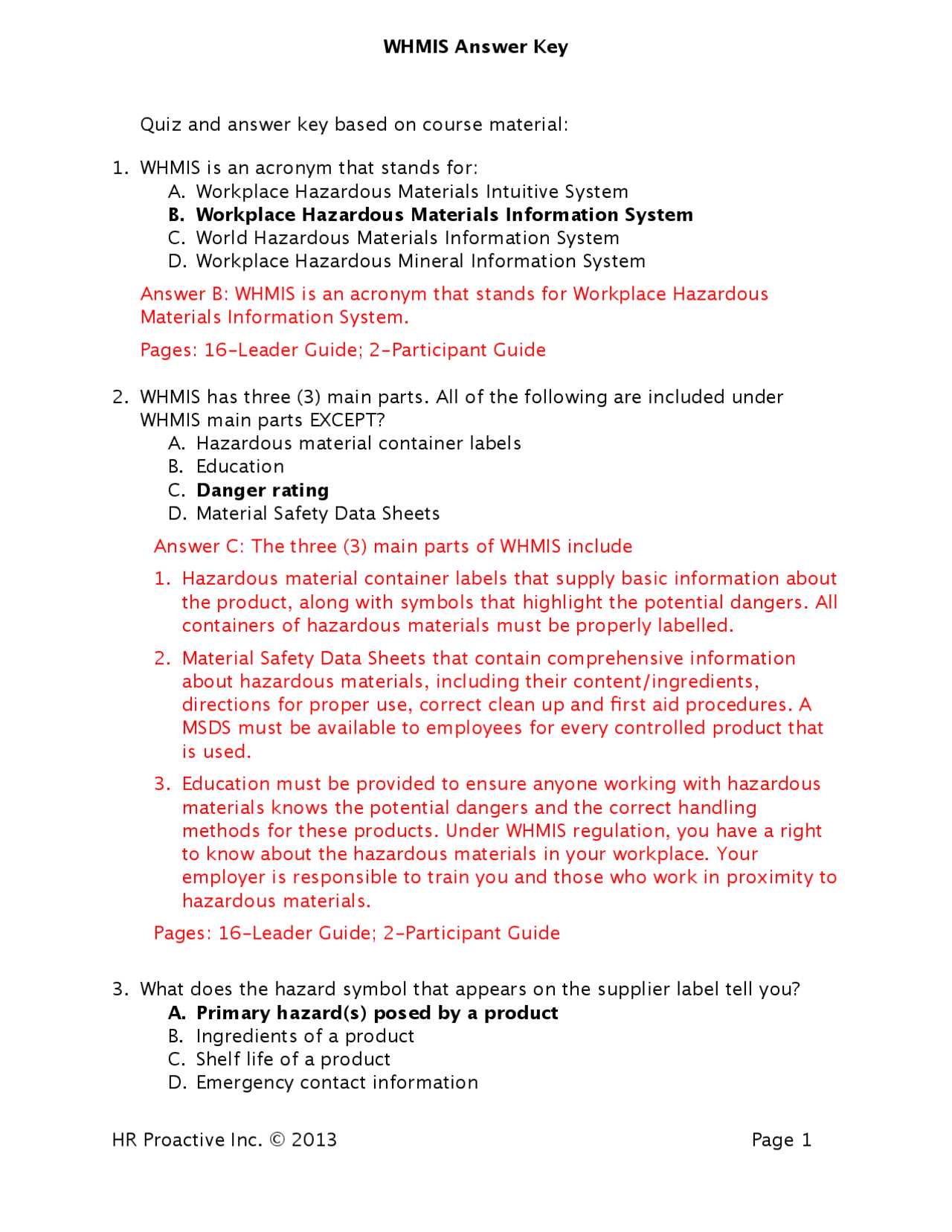

Safety Data Sheet Overview

Safety data sheets (SDS) are essential documents that provide detailed information about hazardous materials used in the workplace. These sheets contain crucial details on how to safely handle, store, and dispose of chemicals or substances, as well as what to do in case of exposure or accidents. The SDS ensures that workers and emergency responders have the information needed to protect themselves from potential harm.

Key Sections of a Safety Data Sheet

- Identification: This section provides the name of the substance, manufacturer contact information, and recommended uses.

- Hazard Identification: Lists the potential hazards associated with the substance, including toxicity, flammability, or environmental impact.

- Composition/Information on Ingredients: Details the chemical composition of the substance and any hazardous components it contains.

- First Aid Measures: Provides instructions on what actions to take in case of accidental exposure, such as inhalation, skin contact, or ingestion.

- Fire-Fighting Measures: Describes the proper methods and equipment for safely fighting a fire involving the substance.

How to Use the Safety Data Sheet

Before working with any hazardous materials, it’s important to carefully review the SDS. Understanding the risks and knowing the emergency procedures can help minimize harm in case of an accident. Always make sure that the SDS is readily accessible in the workplace and that workers are trained on how to interpret and apply the information it contains. This ensures a safer working environment and better preparedness in the event of an emergency.

Top Resources for Safety Training Preparation

Preparing for safety training involves utilizing a variety of resources that help individuals understand the key concepts and protocols associated with handling hazardous materials. These materials provide essential knowledge and practical tips to ensure workers can recognize, assess, and manage risks effectively. From online platforms to official guidelines, there are numerous tools available to assist in building a solid understanding of safety procedures in the workplace.

Online Courses and Platforms

- Interactive Learning Platforms: Websites offering self-paced courses provide detailed lessons on safety standards, hazard identification, and emergency response. These platforms often include quizzes and certifications to ensure knowledge retention.

- Webinars and Online Workshops: Participate in live sessions or recorded workshops led by experts in workplace safety. These interactive formats allow for real-time questions and personalized feedback.

- Mobile Apps: Some mobile applications offer convenient on-the-go access to safety training modules and reference materials, perfect for workers with busy schedules.

Printed Guides and Official Documents

- Safety Data Sheets (SDS): A critical resource in understanding the risks of specific substances, providing comprehensive safety information including handling, storage, and first aid procedures.

- Regulatory Guidelines: National and regional authorities often publish detailed safety guidelines and best practices that align with legal requirements for hazardous materials management.

- Printed Handbooks: Many organizations provide handbooks that summarize key safety concepts, regulatory requirements, and emergency protocols for easy reference in the workplace.

By utilizing these resources, individuals can significantly improve their understanding of safety practices and enhance their preparedness for dealing with hazardous materials effectively. A combination of digital and physical materials offers flexibility and comprehensive training for a variety of learning preferences.

Handling Chemical Hazards at Work

Managing chemical risks in the workplace is a critical aspect of ensuring the safety and well-being of employees. Proper handling, storage, and disposal of hazardous substances are essential practices for minimizing exposure and preventing accidents. Understanding the specific dangers posed by chemicals and knowing how to respond in emergencies can significantly reduce health risks and workplace incidents.

Key Safety Measures for Handling Chemicals

- Use of Personal Protective Equipment (PPE): Always wear the required PPE such as gloves, goggles, aprons, or respirators to protect against chemical exposure.

- Proper Ventilation: Ensure that areas where chemicals are handled are well-ventilated to prevent the buildup of harmful fumes or vapors.

- Safe Storage Practices: Store chemicals according to their specific needs–flammable substances in flameproof cabinets, corrosive chemicals in sealed containers, and toxic materials in designated safety zones.

Understanding Safety Data Sheets (SDS)

Safety Data Sheets are an essential tool for understanding the risks associated with specific chemicals. These sheets provide detailed information on the properties of the substance, proper handling instructions, emergency procedures, and disposal guidelines. Below is a sample table that outlines key sections typically found in an SDS.

| Section | Description |

|---|---|

| Identification | Provides the chemical’s name, manufacturer contact information, and intended use. |

| Hazard Identification | Details the potential risks, such as toxicity, flammability, and health hazards. |

| First Aid Measures | Describes actions to take in case of exposure or accidental injury. |

| Fire-Fighting Measures | Outlines appropriate techniques and equipment to use in case of a chemical fire. |

By following these guidelines and referring to the SDS, workers can better manage chemical hazards and minimize exposure to dangerous substances in the workplace. Proper training and awareness are essential components of any successful safety program.

Best Practices for Safety Training

Effective safety training is a vital part of any workplace, ensuring employees are equipped with the knowledge and skills necessary to work safely with hazardous materials. The goal is to minimize risks, prevent accidents, and enhance overall workplace safety. Implementing best practices in training programs ensures that all workers are well-informed and prepared for any potential dangers they might encounter on the job.

Engaging and Comprehensive Training Programs

- Interactive Learning: Encourage active participation through practical exercises, role-playing scenarios, and interactive modules. This helps learners retain crucial safety procedures.

- Regular Refresher Courses: Safety training should not be a one-time event. Periodic refresher courses keep workers up to date on the latest safety practices and regulatory changes.

- Clear and Accessible Materials: Use clear, easy-to-understand training materials, including visual aids like posters, videos, and charts, to cater to different learning styles.

Tailored Training to Job Roles

- Job-Specific Modules: Customize training content to address the specific risks associated with different roles. For example, employees working in chemical handling should receive targeted instruction on safe chemical practices.

- Scenario-Based Learning: Incorporate real-life case studies and scenario-based training that reflects actual challenges workers might face on the job.

- Hands-On Practice: Whenever possible, provide hands-on training to allow employees to practice using protective equipment, handling hazardous materials, and responding to emergencies in a controlled environment.

By following these best practices, employers can create a training environment that not only meets legal requirements but also fosters a culture of safety and awareness in the workplace. Well-trained employees are better equipped to protect themselves and their colleagues from potential hazards, ensuring a safer and more productive working environment.

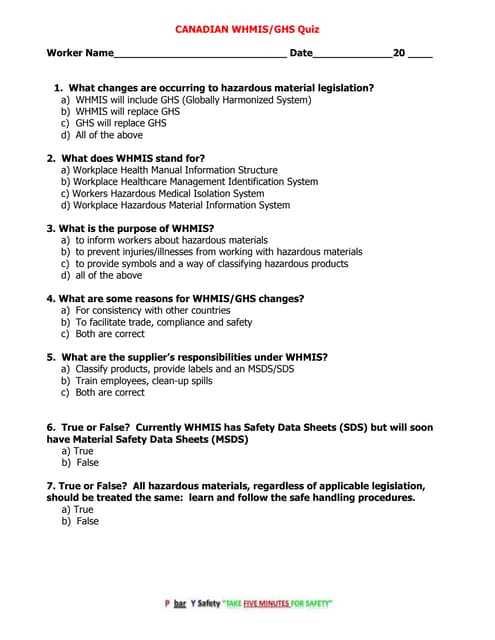

Regulations and Legal Requirements

Workplace safety standards are governed by a set of regulations that ensure the proper handling, labeling, and training concerning hazardous materials. These rules are designed to protect employees from potential health risks associated with exposure to dangerous substances. Adhering to these regulations is not only essential for maintaining a safe work environment but is also a legal requirement for employers. Understanding the legal framework helps both employers and employees comply with safety standards and avoid penalties.

Key Regulatory Bodies and Compliance

- Occupational Health and Safety (OHS) Regulations: These regulations outline the responsibilities of employers to ensure workplace safety, including proper training, labeling, and handling of hazardous materials.

- Labor Laws and Worker Protection Acts: These laws ensure that workers have the right to a safe working environment and are protected from unsafe practices that could lead to exposure to harmful chemicals or substances.

- Local and National Standards: Depending on the region, additional specific regulations may apply, such as national safety programs or regional workplace safety laws.

Employer and Employee Responsibilities

- Employer Responsibilities: Employers are required to provide proper training, hazard communication systems, and necessary protective equipment. They must also ensure that safety data sheets (SDS) are readily accessible to all employees handling hazardous materials.

- Employee Responsibilities: Employees must adhere to safety guidelines, use the provided protective equipment, and report any unsafe conditions or incidents to their supervisors.

By understanding and complying with these legal requirements, organizations can foster a safer work environment, reduce the risk of accidents, and ensure that they are meeting their legal obligations. Compliance not only protects workers but also enhances the overall efficiency and reputation of the organization.

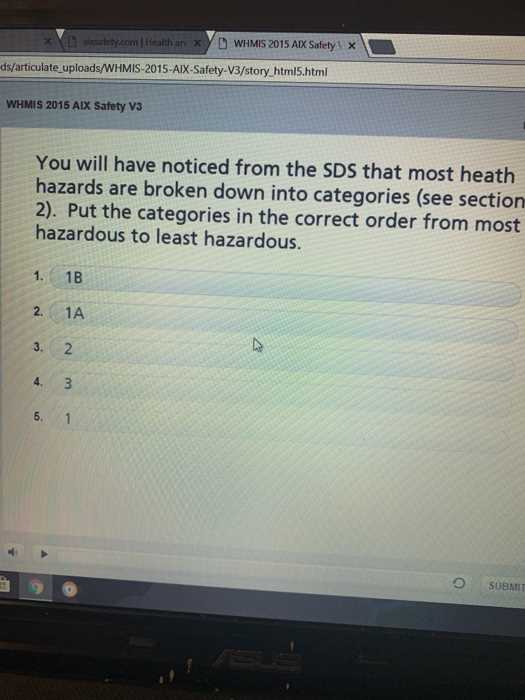

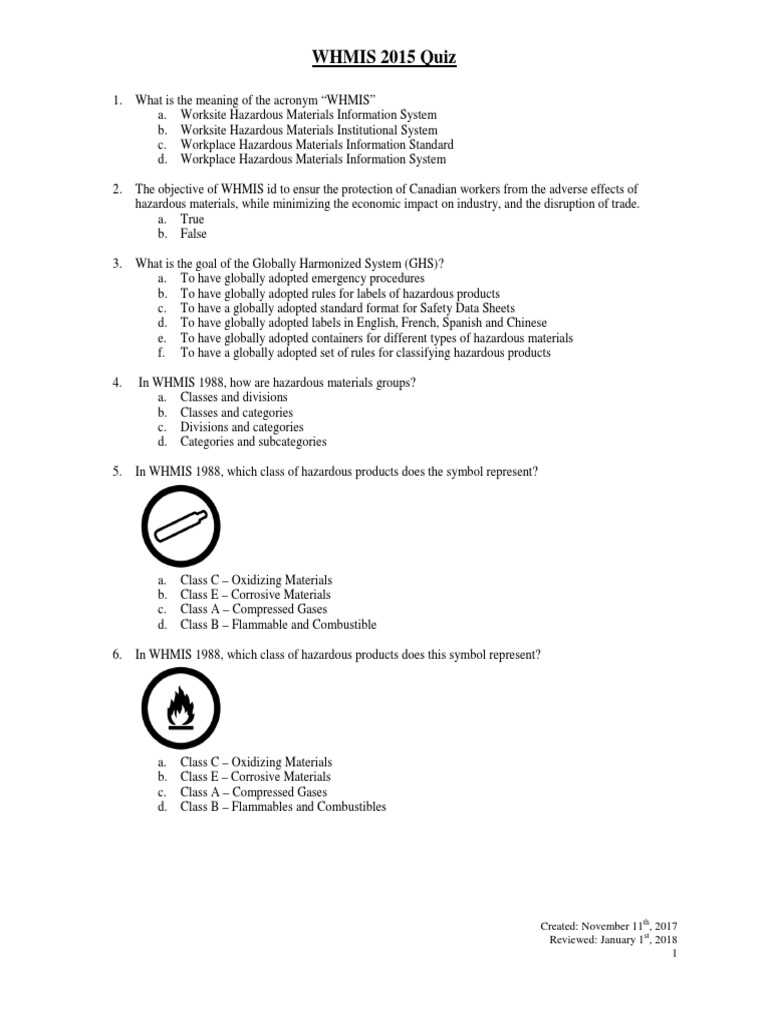

Key Differences in 1988 and 2015 Safety Standards

The evolution of safety regulations has led to significant changes in the way hazardous materials are managed and communicated in the workplace. The transition from the 1988 version of safety standards to the 2015 update introduced important changes in labeling, classification, and training requirements. These changes aim to improve clarity, enhance global compatibility, and provide better protection for workers. Understanding the differences between these two versions is essential for compliance and ensuring safety practices are up to date.

Labeling System Changes

- Symbol Updates: In the 2015 update, hazard symbols were standardized globally. The new system uses pictograms that are easily recognized and understood across borders, replacing some of the older symbols from the 1988 version.

- Label Information: Labels now include more detailed information, such as the supplier’s contact information, the product’s safety measures, and specific hazard warnings. This is a more comprehensive approach compared to the previous label format.

Classification and Training Revisions

- New Hazard Categories: The 2015 version introduced additional hazard classes, providing a more precise classification of chemicals based on their physical and health hazards. This improvement allows for better risk assessment and management.

- Training Requirements: The 2015 update also emphasizes the need for ongoing and updated training, requiring that workers are regularly informed about changes in classification and safety procedures related to hazardous materials.

By understanding these key differences, employers can ensure their practices meet current standards, helping to protect their workforce and remain compliant with the law. Regular training and updating of safety materials are essential to adapt to these changes and maintain a safe working environment.

What to Expect on the Safety Standards Test

When preparing for a test focused on workplace safety and hazardous materials handling, it’s important to understand the types of questions and the areas covered. The test typically assesses your knowledge of safety regulations, hazard identification, proper labeling, and emergency procedures. Knowing what to expect can help you approach the test confidently and ensure you are fully prepared.

Topics Covered in the Test

- Hazard Classification: You will be tested on identifying different categories of hazardous materials, understanding their risks, and knowing the proper precautions to take when handling them.

- Labeling and Symbols: The test will include questions on the various safety symbols, pictograms, and labels used to indicate the presence of dangerous substances, and what each symbol represents.

- Safety Measures: Questions may focus on the necessary protective equipment, first aid measures, and emergency procedures to follow in case of exposure or accidents involving hazardous materials.

- Regulatory Knowledge: You will need to demonstrate an understanding of the regulations governing workplace safety and the roles and responsibilities of employers and employees in maintaining a safe working environment.

Test Format and Tips

- Multiple Choice and True/False: The test is often composed of multiple-choice questions and true/false statements designed to assess your understanding of the key concepts.

- Practical Application: You may be asked to apply your knowledge to hypothetical scenarios, such as how to handle a chemical spill or identify hazardous materials in a workplace.

- Preparation: To succeed, review study materials, practice identifying safety symbols, and familiarize yourself with the regulations that govern hazardous material management.

By focusing on these areas, you can be well-prepared to demonstrate your knowledge and pass the test with confidence. Understanding both the theoretical and practical aspects of safety standards will ensure you are equipped to handle workplace hazards effectively.

Exam Strategy for Safety Standard Questions

Approaching a test on workplace safety and hazardous material handling requires a well-thought-out strategy. With a clear plan in place, you can tackle the questions more effectively, manage your time wisely, and increase your chances of success. By focusing on key areas, understanding the structure, and applying efficient test-taking techniques, you will be better prepared to handle even the most challenging questions.

Time Management and Focus

- Read Questions Carefully: Before answering, make sure to carefully read each question. Pay attention to key phrases that indicate what is being asked, such as “best” or “most important.”

- Prioritize Easy Questions: Start by answering questions you are most confident about. This will build momentum and ensure you’re not wasting time on difficult questions early on.

- Allocate Time Wisely: Keep an eye on the clock and allocate time based on the number of questions. If you find yourself spending too much time on one, move on and return to it later if necessary.

Effective Answering Techniques

- Eliminate Incorrect Options: For multiple-choice questions, rule out obviously incorrect answers first. This increases your odds of choosing the correct one even if you’re unsure.

- Use Your Knowledge of Safety Standards: Many questions will be based on established safety protocols. If you’re not sure about a specific scenario, think about the most common safety practices in hazardous material management.

- Double-Check Your Work: If time allows, review your answers before submitting the test. Look for errors in understanding or misinterpreted questions, and make corrections where necessary.

By following these strategies, you can approach the test with confidence and maximize your chances of success. A clear focus on the essentials, along with careful attention to detail, will help you navigate the questions effectively and perform your best.

How to Improve Your Safety Knowledge

To enhance your understanding of workplace safety standards and hazardous material handling, it’s important to focus on both theoretical learning and practical application. Gaining a deeper knowledge will not only help you stay compliant but also ensure a safer environment for everyone. Consistent study, hands-on experience, and utilizing various resources are key to mastering essential safety protocols.

Study the Core Principles

- Review Safety Guidelines: Regularly go over the core safety protocols and guidelines. Familiarize yourself with the most common safety procedures for handling chemicals and dangerous materials.

- Understand Key Terms: Focus on learning the key terms and classifications used in safety regulations. This knowledge will help you quickly identify and manage potential risks in the workplace.

- Use Available Resources: Take advantage of manuals, online courses, and training materials that provide in-depth explanations of safety standards and hazard management.

Engage with Practical Training

- Participate in Workshops: Attend workshops or training sessions to get hands-on experience with the equipment and materials commonly used in hazardous environments. Real-world practice is invaluable for reinforcing your theoretical knowledge.

- Ask for Mentorship: Seek guidance from experienced professionals in your workplace. They can provide practical insights and answer questions you might have about specific safety procedures.

- Practice Safety Drills: Participate in mock safety drills to practice your response in emergency situations. This can help you develop quick decision-making skills and improve your overall safety awareness.

By continually refining your knowledge and staying up to date with new safety standards and regulations, you can improve your competence in managing workplace hazards effectively and ensure a safe working environment for everyone.

Common Mistakes in Safety Assessments

While preparing for safety assessments, many individuals make certain mistakes that can hinder their understanding and ability to apply key concepts effectively. These errors often stem from lack of focus, misinterpretation of guidelines, or insufficient practice. Understanding and avoiding these common pitfalls can significantly improve both knowledge retention and performance in safety training evaluations.

Misunderstanding Hazardous Material Classifications

- Overlooking Proper Labeling: Failing to correctly identify hazardous materials and their corresponding labels is a common mistake. Each chemical or substance has specific symbols and classifications that must be memorized to ensure safe handling and storage.

- Confusing Risk Factors: Sometimes individuals misjudge the level of risk associated with certain chemicals or materials. Properly assessing the danger and understanding its impact on health and the environment is critical for safety.

- Not Recognizing Safety Features: Ignoring safety features such as ventilation requirements or protective equipment needed when handling hazardous materials can lead to dangerous situations.

Failure to Follow Procedures

- Skipping Safety Protocols: Some individuals assume they can skip steps in the safety procedure, such as checking labels or wearing the necessary personal protective equipment (PPE). This neglect increases the risk of accidents.

- Improper Emergency Responses: Not being familiar with emergency response protocols can lead to serious mistakes during critical situations. Practicing correct actions in case of a chemical spill or accident is essential.

- Inconsistent Training: Inadequate review of materials and training resources can cause lapses in memory, resulting in a failure to recall key safety steps when required.

By identifying these common mistakes and actively working to correct them, individuals can enhance their overall safety knowledge and improve their ability to handle hazardous situations confidently and correctly.