For anyone looking to work with modern cooling systems, it’s crucial to have a solid understanding of the latest industry standards and techniques. In this guide, we will help you navigate the essential knowledge needed for professionals seeking to prove their expertise in handling advanced refrigerants and systems. Whether you’re just starting or preparing to validate your skills, understanding the key concepts is the first step toward success.

Achieving proficiency in this area requires more than just basic technical knowledge. It involves mastering a range of topics, from safety protocols to the intricate details of system maintenance. By familiarizing yourself with the core principles and gaining hands-on experience, you will be well-prepared for any challenge in the field.

Preparation is the foundation for success in this field. A structured approach to studying and testing your knowledge will ensure that you are ready to face real-world challenges with confidence. In this article, we’ll break down the most important topics, offer valuable tips, and provide insight into the best practices for staying ahead in the industry.

Universal R 410A Certification Exam Answers

For those seeking to demonstrate their expertise in advanced refrigeration systems, it is essential to be prepared for various assessment challenges. This section will explore key insights and practical approaches to handling the test. Understanding the subject matter thoroughly will not only increase your chances of success but also enhance your ability to perform effectively in the field.

Key Topics to Focus On

During the evaluation, there are several critical areas to concentrate on. These include the properties of refrigerants, system safety, and the various methods for troubleshooting common issues. By focusing on these areas, you ensure a deeper understanding and greater proficiency when faced with the assessment.

Effective Strategies for Success

To succeed, candidates should take a methodical approach. Begin by reviewing the fundamental concepts, and then tackle practice questions to gauge your understanding. Focus on time management and prioritizing areas where you feel least confident.

| Topic | Recommended Focus |

|---|---|

| Refrigerant Properties | Understanding the chemical and physical characteristics of cooling agents |

| System Maintenance | Learning routine procedures for system upkeep and efficiency |

| Safety Protocols | Familiarizing yourself with proper handling, storage, and leak prevention |

| Troubleshooting | Developing skills for diagnosing and resolving system issues |

Overview of the R 410A Certification

The process of validating your knowledge and skills in the field of refrigeration systems is essential for professionals who want to excel in handling modern cooling technologies. This qualification proves that you understand the key principles required for safe and efficient operation, including the handling and maintenance of specific refrigerants used in advanced systems. By mastering the fundamentals, individuals can demonstrate their ability to manage complex tasks and meet industry standards.

Importance of Certification

Having a recognized qualification in this field not only enhances your career prospects but also ensures that you are equipped to meet the growing demand for skilled professionals. This recognition is crucial for those who wish to work with the latest technologies and maintain the safety and efficiency of high-performance systems. In addition, it reflects your commitment to following industry best practices and meeting regulatory requirements.

What’s Covered in the Qualification

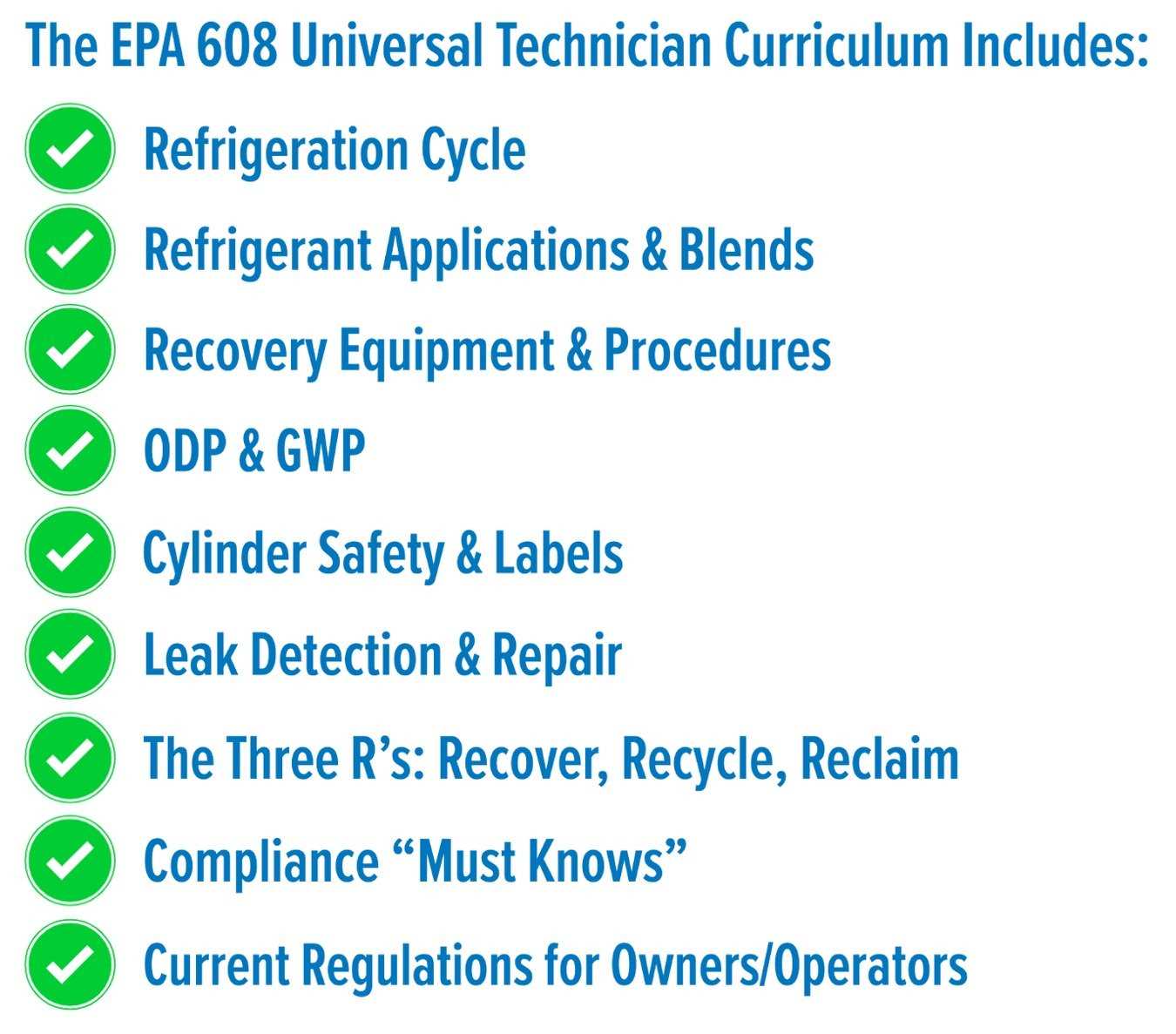

During the assessment process, candidates are tested on various aspects of refrigeration, from the technical specifications of different systems to the safety protocols necessary for working with cooling agents. The scope of this qualification covers key topics such as system diagnostics, maintenance techniques, and compliance with environmental standards. A strong grasp of these areas is essential to succeed in real-world scenarios.

Why R 410A Certification is Important

Gaining proficiency in handling advanced refrigerants and cooling systems is essential for professionals in the field of HVAC. Obtaining a recognized qualification ensures that you possess the necessary skills and knowledge to work safely and efficiently with modern refrigeration technologies. This certification not only demonstrates your technical expertise but also enhances your credibility in the industry.

Here are some reasons why obtaining this qualification is crucial:

- Compliance with Industry Standards: Professionals are required to meet regulatory standards, ensuring safe practices when working with refrigerants.

- Increased Job Opportunities: Having this qualification opens doors to more career prospects, as employers seek certified technicians to handle complex systems.

- Improved Safety Awareness: Understanding proper procedures reduces the risks associated with working with potentially hazardous materials, protecting both workers and the environment.

- Enhanced Earning Potential: Technicians with recognized credentials are often able to command higher wages and secure more prestigious roles in the industry.

For those looking to advance in this field, obtaining this qualification is a crucial step toward ensuring long-term success and professional growth. The knowledge gained will not only prepare you for industry challenges but also improve your overall effectiveness in system management and maintenance.

Exam Format and Structure Explained

Understanding the format and structure of the assessment is a key part of preparing for any professional qualification. This section will guide you through the essential components of the test, so you can approach it with confidence and clarity. By familiarizing yourself with the types of questions and the overall layout, you can develop an effective strategy for tackling each section.

Types of Questions

The assessment typically includes a mix of multiple-choice questions and scenario-based problems. Multiple-choice questions test your theoretical understanding, while scenario questions assess your ability to apply that knowledge to real-world situations. It’s important to focus on both technical knowledge and practical problem-solving skills to succeed.

Structure of the Assessment

The structure of the test is designed to assess a wide range of competencies, ensuring that you are equipped with the necessary skills for the job. The test is divided into sections, each focusing on different aspects of refrigeration systems. Below is a breakdown of the structure:

| Section | Content Focus | Question Type |

|---|---|---|

| Refrigerant Properties | Understanding different refrigerants and their applications | Multiple-choice, True/False |

| System Maintenance | Procedures for maintaining and servicing systems | Scenario-based, Multiple-choice |

| Safety Protocols | Best practices for handling refrigerants safely | Multiple-choice, Matching |

| Troubleshooting | Diagnosing and fixing system issues | Scenario-based, Multiple-choice |

Being familiar with the structure will help you manage your time effectively and prioritize your study efforts based on the sections that matter most. The key to success is thorough preparation and a clear understanding of the areas that will be evaluated.

Key Topics Covered in the Exam

When preparing for an assessment in the field of refrigeration and cooling systems, it is crucial to understand the primary areas of focus. The test evaluates a range of topics, ensuring that candidates are well-versed in both theoretical knowledge and practical application. Mastering these key subjects will ensure you are fully prepared to handle real-world challenges in the industry.

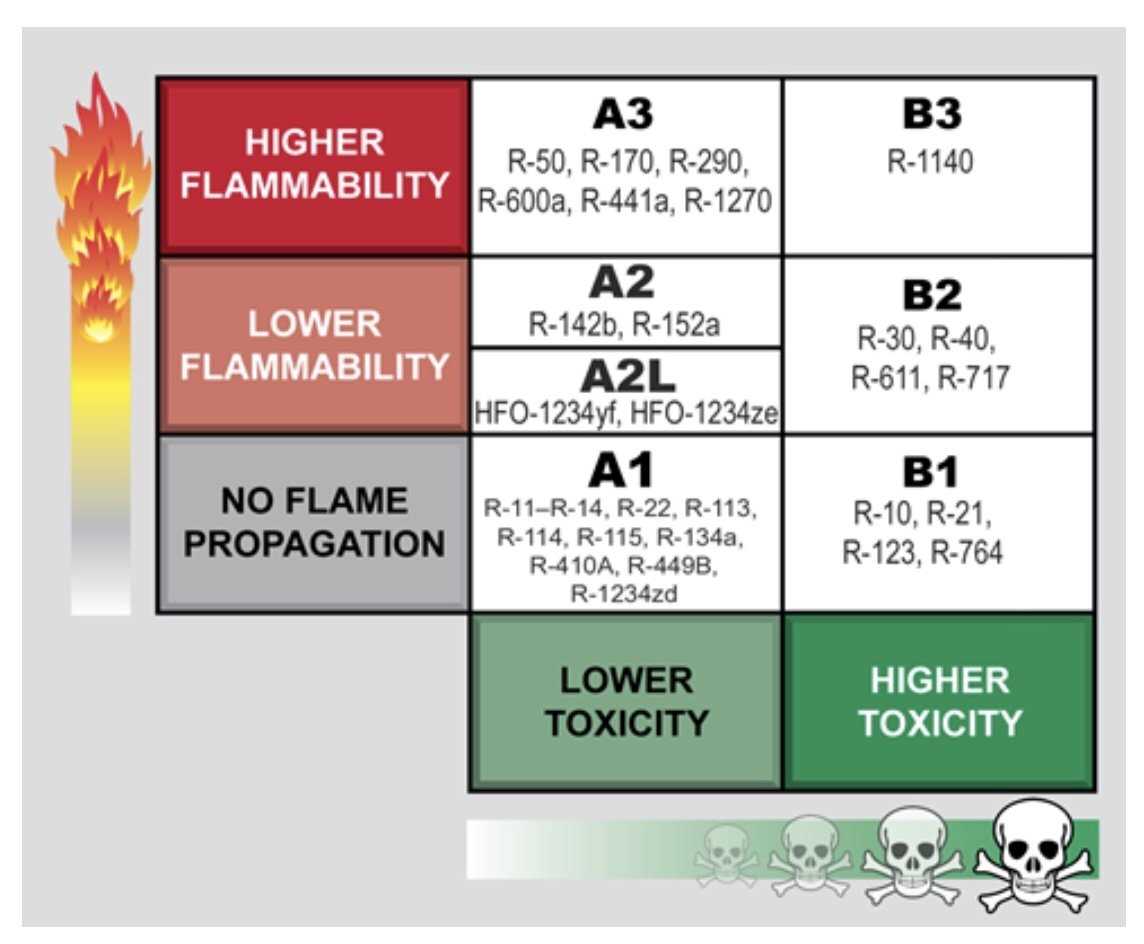

Refrigerant Properties and Applications

One of the core topics covered in the evaluation is the study of refrigerants. Candidates are expected to understand the various types of cooling agents, their chemical properties, and how they interact with different systems. This section also covers the applications of these refrigerants in a variety of environments, ensuring that professionals can select the appropriate substance for each task.

System Design, Maintenance, and Troubleshooting

Another important area of focus is system maintenance and troubleshooting. The ability to design, repair, and maintain cooling systems is a critical skill in the industry. This part of the test evaluates your understanding of proper installation techniques, routine maintenance procedures, and methods for diagnosing and resolving common system issues. A solid grasp of these topics is essential for keeping systems running smoothly and efficiently.

How to Prepare for the R 410A Exam

Preparation is key to performing well in any professional assessment. To succeed, you must familiarize yourself with the core topics and understand the practical applications of the knowledge you’ve gained. This section will outline effective strategies to help you prepare thoroughly, ensuring that you are ready for the challenges the test will present.

Study the Key Areas

To maximize your chances of success, focus on the most relevant topics. Below are some of the key areas you should concentrate on:

- Refrigerant Characteristics: Understand the properties, handling, and safety of various refrigerants used in modern systems.

- System Troubleshooting: Learn how to diagnose and resolve common issues that may arise in refrigeration systems.

- Safety Standards: Familiarize yourself with industry safety protocols to ensure compliance and avoid hazards.

- Maintenance Procedures: Study the correct maintenance and servicing techniques to keep systems functioning optimally.

Use Practice Materials

Engage with practice questions and mock tests to familiarize yourself with the test format and improve your time management. This will help reinforce your knowledge and build confidence for the real assessment. Additionally, consider using textbooks, online resources, and training workshops to gain a deeper understanding of complex concepts.

By taking a structured approach to your preparation, you can feel confident and well-equipped when the time comes to take the test.

Common Mistakes to Avoid During the Exam

During any professional assessment, it’s easy to fall into certain traps that can negatively impact your performance. These mistakes, whether related to time management, understanding the questions, or overlooking key details, can all lead to unnecessary errors. By being aware of these common pitfalls, you can approach the test with greater confidence and reduce the risk of making avoidable mistakes.

Common Pitfalls to Watch Out For

- Rushing Through Questions: It’s important not to rush through the questions, as this can lead to careless mistakes. Take the time to read each question carefully and consider all options before selecting your answer.

- Neglecting to Review Answers: If time permits, always review your answers before submitting. It’s easy to miss small details or make simple errors that can be caught on a second read-through.

- Overlooking Safety Procedures: Safety protocols are often a significant portion of the test. Failing to pay close attention to safety standards and proper handling techniques can result in incorrect answers, particularly in scenario-based questions.

- Not Managing Time Properly: Allocate time for each section and stick to it. Spending too much time on a single question can prevent you from completing the rest of the test. Prioritize questions you find easiest and return to the more difficult ones if you have time left.

- Ignoring Practical Application: Some questions may test your ability to apply knowledge in real-world scenarios. Ensure that you understand not just theoretical concepts but also how to implement them practically in the field.

How to Avoid These Mistakes

- Practice Time Management: Before the test, practice under timed conditions to get used to the pace of the assessment.

- Familiarize Yourself with Common Scenarios: Study past scenarios and common issues that might arise in real-world refrigeration systems.

- Stay Calm and Focused: Avoid panic and take deep breaths. Staying calm helps you think more clearly and make better decisions.

By avoiding these common mistakes, you can ensure a smoother testing experience and increase your chances of success.

Study Resources for R 410A Certification

Effective preparation for any professional qualification requires the right resources. The best materials help reinforce key concepts, enhance your understanding, and provide real-world application examples. This section will guide you through various study tools and resources that can assist you in mastering the essential topics and skills required for success in your assessment.

Books and Manuals

Comprehensive study guides and manuals are essential for in-depth learning. These resources cover everything from theoretical knowledge to practical tips, often with detailed explanations and illustrations. Consider the following types of materials:

- Technical Reference Guides: These guides provide detailed descriptions of refrigeration systems, safety protocols, and industry standards.

- Practice Test Books: Books with practice tests and multiple-choice questions are great for testing your knowledge and preparing for the format of the assessment.

- Manufacturer Manuals: Reviewing manuals from manufacturers of cooling systems can offer practical insights into system setup, maintenance, and troubleshooting.

Online Courses and Videos

Many platforms offer online courses designed specifically for refrigeration and system management professionals. These courses often include video tutorials, interactive quizzes, and guided exercises. Some platforms to explore include:

- Online Training Platforms: Websites like Coursera, Udemy, and LinkedIn Learning offer specialized courses in refrigeration systems.

- YouTube Channels: Channels dedicated to HVAC training can be a great way to see real-life examples of system installations and repairs.

- Webinars and Workshops: Participate in live webinars or workshops conducted by industry professionals to stay up to date with the latest techniques and regulations.

Combining these resources with hands-on practice will help ensure that you’re fully prepared for your assessment, giving you the confidence to tackle any challenge that comes your way.

Top Tips for Passing the Certification

Achieving success in any professional qualification requires more than just basic knowledge. To truly excel, you must approach the preparation process with a strategic mindset. In this section, we’ll share practical tips to help you improve your performance and pass with confidence. These strategies focus on optimizing your study methods, enhancing your understanding, and managing your time effectively during the assessment.

1. Master the Fundamentals

Before diving into complex scenarios, ensure you have a solid understanding of the fundamental concepts. Focus on key areas such as refrigeration systems, safety protocols, and troubleshooting. A strong foundation in these basics will make it easier to tackle more advanced questions later on.

2. Practice Regularly

Frequent practice with mock tests and practice questions will help reinforce your knowledge and familiarize you with the format of the assessment. The more you practice, the more confident and efficient you’ll become when answering questions under timed conditions.

3. Stay Organized

Create a structured study schedule that breaks down topics into manageable sections. This will help you stay on track and ensure you cover everything needed for the assessment. Stick to your schedule, and avoid cramming the night before the test.

4. Review Safety Standards

Pay particular attention to safety protocols, as they are often a major component of the assessment. Understanding and applying safety standards not only ensures compliance but also improves your chances of success in practical scenario-based questions.

5. Take Breaks and Rest

Don’t overlook the importance of rest. Regular breaks during study sessions help prevent burnout and improve focus. Ensure you get plenty of rest the night before the assessment to be fully alert and ready to perform your best.

By following these tips and maintaining a disciplined study routine, you will be well-prepared and positioned for success when it’s time to take the test.

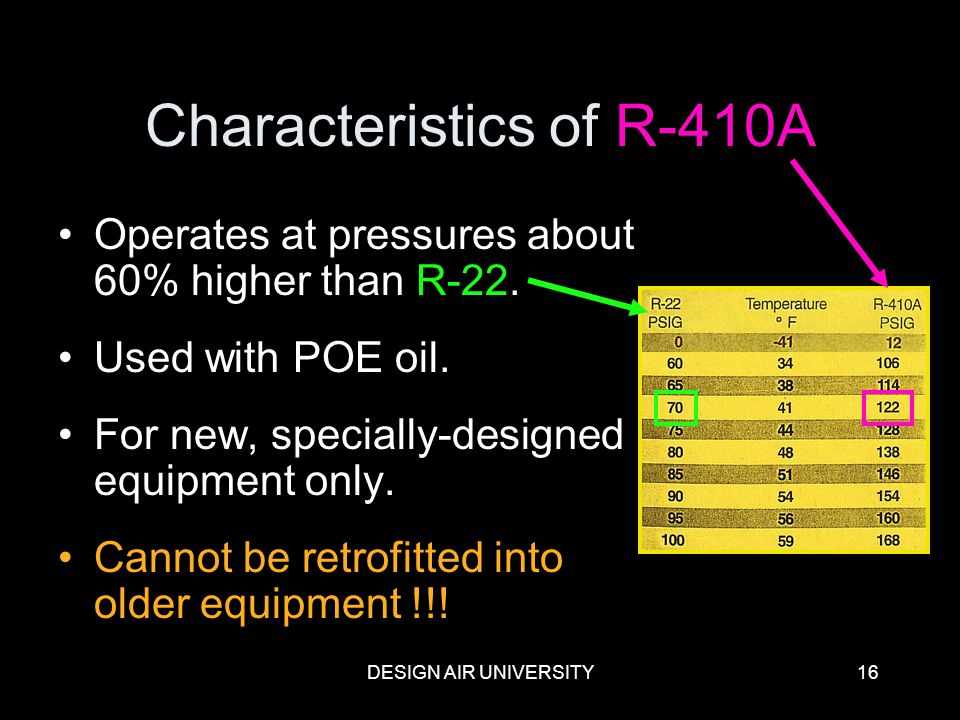

Understanding R 410A Refrigerant Basics

Refrigerants play a crucial role in modern cooling and heating systems, and understanding their properties is essential for anyone working with HVAC systems. This section will cover the fundamentals of a widely used refrigerant, focusing on its composition, applications, and key characteristics. Understanding these basics will not only help in system design and maintenance but also ensure that safety standards are met in everyday use.

Key Characteristics of the Refrigerant

This particular refrigerant is known for its efficiency and environmentally-friendly properties compared to older alternatives. It has a high cooling capacity, which makes it ideal for use in air conditioning units and heat pumps. Below is a table outlining some of the important physical and chemical properties that define this substance:

| Property | Value |

|---|---|

| Global Warming Potential (GWP) | 2088 |

| Ozone Depletion Potential (ODP) | 0 |

| Critical Temperature | 72.1°C |

| Boiling Point | -48.5°C |

| Chemical Formula | C5H10 |

Applications and Uses

Due to its high efficiency and low environmental impact, this refrigerant is commonly used in residential and commercial cooling systems. It is frequently found in modern air conditioners, heat pumps, and refrigeration equipment. Because of its ability to work effectively under a wide range of temperatures and pressures, it has become a standard choice for system designers and technicians looking for reliable performance.

Proper handling, storage, and disposal are essential to prevent any negative impact on the environment and ensure system longevity. Technicians must be familiar with safety procedures to avoid mishandling this refrigerant during installation or maintenance.

Importance of Safety in Refrigeration Systems

Refrigeration systems are essential for maintaining controlled temperatures in a variety of applications, from home appliances to large industrial setups. However, like any mechanical system, they can pose risks if not properly handled. Safety in refrigeration systems is a critical aspect that cannot be overlooked. Proper understanding of the associated risks, along with following safety guidelines, ensures both efficient operation and protection for the technician, the environment, and the system itself.

Common Hazards in Refrigeration Systems

Refrigeration units involve pressurized gases, electrical components, and complex moving parts, all of which present potential hazards. The most common risks include:

- Leaks of refrigerant: Escaping gases can be hazardous to health and the environment, especially if not handled with care.

- Electrical hazards: Faulty wiring or improper grounding can lead to shocks or fires.

- Overheating: Ineffective cooling or blocked air flow may cause components to overheat and malfunction.

- Mechanical failure: Malfunctions in compressors or fans can lead to system breakdowns and potential injuries during maintenance.

Best Practices for Ensuring Safety

To minimize these risks, it’s crucial for professionals to adhere to a set of safety best practices, including:

- Use personal protective equipment (PPE): Always wear appropriate safety gear, such as gloves, goggles, and insulated footwear, when handling refrigeration systems.

- Proper training and certification: Ensure all technicians are adequately trained in handling refrigerants and electrical components safely.

- Regular maintenance: Perform routine checks to identify any potential issues before they escalate into dangerous problems.

- Ventilation: Make sure the work area is well-ventilated to prevent the accumulation of gases and maintain air quality.

By following these safety guidelines, refrigeration professionals can significantly reduce risks and ensure that their systems remain efficient, reliable, and safe for long-term use.

What to Expect During the R 410A Test

When preparing for a professional assessment in the field of refrigeration and air conditioning, it’s essential to understand what the process involves. The test is designed to evaluate your knowledge of safe practices, technical expertise, and ability to work with specific refrigerants. Here, we will explore what you can expect during the assessment, including the format, the types of questions, and the skills that will be evaluated.

Typically, the assessment will consist of two key components: a theoretical part and a practical part. The theoretical section will focus on understanding the chemical properties of refrigerants, safety guidelines, and the general operation of HVAC systems. The practical portion will require you to demonstrate hands-on skills, such as handling equipment and troubleshooting common issues.

During the theoretical portion, expect to answer questions on:

- The role of refrigerants in cooling systems

- Environmental impacts and regulations

- System maintenance and troubleshooting methods

- Safety protocols for handling refrigerants

On the practical side, you will likely be asked to perform tasks such as:

- Correctly identifying and addressing refrigerant leaks

- Conducting safety checks on refrigeration equipment

- Demonstrating effective system charging procedures

Being well-prepared for both theoretical and practical components will help ensure a successful outcome. By reviewing the key concepts and practicing hands-on skills, you can approach the test with confidence and demonstrate your expertise in handling refrigeration systems.

Recommended Books and Materials for Preparation

To effectively prepare for the assessment in the refrigeration field, it is crucial to have access to the right study materials. Books, online resources, and manuals designed for professionals working with HVAC systems provide valuable insights and detailed explanations of concepts. Below are some recommended resources that can help enhance your understanding and boost your confidence before the test.

Essential Books for Study

- The HVAC R Technician’s Guide: This book provides comprehensive coverage of refrigeration systems, including the principles of operation, maintenance, and safety protocols.

- Refrigeration and Air Conditioning Technology: A widely respected textbook that covers both theoretical concepts and practical techniques, ideal for both beginners and advanced learners.

- The Complete HVAC/R Service Handbook: This resource offers a hands-on approach, with real-world examples of troubleshooting, system diagnostics, and detailed information about refrigerants.

Additional Resources for Thorough Preparation

- Online Courses and Tutorials: Platforms like Coursera, Udemy, and LinkedIn Learning offer courses focusing on refrigeration systems, including specific refrigerants and their applications.

- Manufacturer’s Manuals: Always refer to manuals from equipment manufacturers. These provide technical details and guidelines specific to various HVAC systems, which will be important during the practical part of the assessment.

- Practice Tests: Mock tests or quizzes found online can help you familiarize yourself with the types of questions and scenarios you may encounter during the assessment.

Using a variety of study materials will ensure a well-rounded understanding of both the theoretical and practical aspects of refrigeration systems. Combine books, online resources, and hands-on practice to maximize your preparation and increase your chances of success.

Practice Questions for R 410A Exam

One of the most effective ways to prepare for any certification related to refrigeration systems is to familiarize yourself with potential questions that might appear. Practicing questions will help you test your knowledge, identify areas where you may need further review, and build confidence before taking the actual assessment. Below are some practice questions designed to test your understanding of key concepts in refrigerant handling, system components, and safety protocols.

Sample Questions

- What is the primary function of a compressor in a refrigeration system?

- A. To circulate the refrigerant

- B. To cool the refrigerant

- C. To compress the refrigerant for heat exchange

- D. To release refrigerant into the environment

- Which of the following safety precautions should be followed when handling refrigerants?

- A. Always wear gloves and safety goggles

- B. Work in an enclosed space to avoid ventilation

- C. Use refrigerants near open flames for testing

- D. Keep refrigerant containers open to release pressure

- What is the importance of understanding refrigerant pressure-temperature (P-T) charts?

- A. To monitor system energy efficiency

- B. To determine appropriate refrigerant charge levels

- C. To adjust the system’s power output

- D. To troubleshoot compressor malfunctions

Answer Key

- Q1: C. To compress the refrigerant for heat exchange

- Q2: A. Always wear gloves and safety goggles

- Q3: B. To determine appropriate refrigerant charge levels

By practicing these types of questions, you can strengthen your understanding of critical concepts and ensure you’re well-prepared for any challenges you may face in the assessment. Always remember to review your responses and understand why each correct answer is right to improve your knowledge further.

Exam Registration and Requirements

Before taking any professional assessment in the field of refrigeration and HVAC, it is important to understand the registration process and requirements to ensure you meet all the necessary criteria. Proper preparation includes knowing the prerequisites for enrollment, understanding the necessary qualifications, and submitting required documentation on time. This section outlines the essential steps involved in registering for the examination and provides an overview of the eligibility requirements.

Eligibility Requirements

- Age Requirement: Candidates must be at least 18 years old to apply.

- Experience: A certain number of hours working in the field may be required. Typically, applicants need to demonstrate experience with refrigerants, system installation, and troubleshooting.

- Educational Background: Although formal education is not always mandatory, it is recommended to have foundational knowledge in HVAC systems or related fields.

- Training: Some assessments may require proof of prior training in handling refrigerants or HVAC systems, either through formal courses or on-the-job experience.

Registration Process

Once you meet the eligibility criteria, you can begin the registration process. This typically involves the following steps:

- Fill out the Registration Form: The first step is to complete the registration form, which can usually be found on the official website of the certifying body.

- Submit Required Documents: You may need to provide documents such as proof of work experience, training certifications, and identification.

- Pay the Registration Fee: Most assessments require a fee for registration. This can often be paid online via credit card or through other accepted methods.

- Confirm Your Enrollment: Once all steps are completed, you will receive confirmation of your registration. Keep this for reference as it may include important dates and instructions.

It is crucial to ensure that all required documents are submitted accurately and on time to avoid delays in the registration process. Each certification body may have slightly different requirements, so it is advisable to check their official guidelines to ensure compliance.

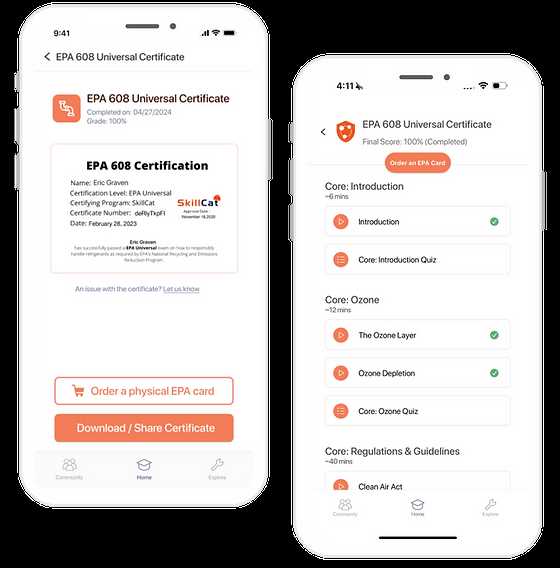

Next Steps After Passing the Certification

Once you have successfully completed the assessment and received your professional credentials, it’s important to understand what comes next in your career journey. This achievement opens up new opportunities in the field and may require additional steps to fully leverage your skills and knowledge. In this section, we will explore the key actions you should take after obtaining your qualification.

Updating Your Professional Profile

After passing the assessment, one of the first things you should do is update your professional profile. This includes adding your new qualifications to your resume, online job platforms, and any professional networks you are part of. Ensuring that your credentials are visible helps you stand out to potential employers and clients.

- Resume Update: Include your newly acquired skills and qualifications in the education or certifications section of your resume.

- LinkedIn Profile: Add your credential to your LinkedIn profile to make it visible to recruiters and other industry professionals.

- Job Portals: Make sure your qualifications are reflected on any job portals where you have a profile, such as Indeed, Glassdoor, or others relevant to your field.

Seeking New Opportunities

Passing the assessment demonstrates your competence and can open doors to new job opportunities. Here are a few steps to help you capitalize on your achievement:

- Apply for Relevant Positions: Start applying for positions that align with your newly acquired skill set. Many companies seek professionals with advanced knowledge in refrigerants and system management.

- Explore Freelance Opportunities: If you prefer more flexibility, consider offering your services as a contractor or consultant in refrigeration-related tasks.

- Network with Industry Professionals: Attend industry events, workshops, and conferences to meet others in the field. Networking can often lead to job referrals or new opportunities.

With your certification in hand, you are now better equipped to take on more advanced roles in the industry. Stay informed about new technologies, safety regulations, and industry best practices to keep advancing your career.