In the world of culinary service, understanding best practices for hygiene and safety is crucial to maintaining a healthy environment. Whether you are preparing, storing, or serving items, following industry standards not only ensures quality but also protects public health. This section focuses on key concepts, highlighting the necessary steps to avoid contamination and potential health risks in a professional setting.

Comprehending the fundamental principles behind safe operations is vital. Knowing how to handle products correctly, maintain clean environments, and follow regulations is the foundation of a well-functioning kitchen or service area. Having this knowledge allows workers to make informed decisions that directly contribute to the safety and success of the establishment.

For those looking to achieve certification, it’s important to grasp the core concepts tested in evaluations. By focusing on prevention strategies, hygiene practices, and temperature controls, individuals can demonstrate competence and confidence in their roles, ensuring a safe experience for customers and colleagues alike.

Safer Food Handler Exam Answers

In the realm of culinary safety, achieving proficiency in critical safety principles is essential for all professionals. Understanding the practices that minimize risks and ensure sanitary conditions in every step of food preparation and service is a fundamental skill. To assess this knowledge, individuals are often required to demonstrate their understanding through structured evaluations, which cover a variety of relevant topics.

To succeed in these assessments, it is important to focus on key areas such as personal hygiene, temperature control, and prevention of cross-contamination. A solid grasp of these core principles will not only help candidates pass the test but also prepare them for real-world application in their daily tasks. Emphasis should be placed on identifying the most common hazards and understanding how to mitigate them effectively.

Practicing with sample questions that cover a wide range of potential scenarios can further enhance preparation. Being familiar with the common issues that arise in the workplace, such as proper storage techniques or cleaning protocols, will give individuals the confidence to navigate the assessment and demonstrate their competence.

Understanding Food Safety Standards

Maintaining a high standard of cleanliness and hygiene is essential in every aspect of a kitchen or service environment. Regulations are put in place to ensure that risks are minimized, and safe practices are followed to prevent contamination. These guidelines cover everything from handling raw ingredients to the final steps of serving food, ensuring that safety remains a top priority throughout the entire process.

Key Principles of Hygiene and Safety

Adhering to basic hygiene and sanitation principles is the cornerstone of any professional kitchen. This includes regular handwashing, proper use of protective gear, and maintaining clean workspaces. A strong understanding of these practices helps in creating an environment that is free from harmful bacteria and pathogens.

Temperature Control and Its Importance

Another crucial element of safety standards is temperature control. Both hot and cold items must be stored, cooked, and served at the correct temperatures to avoid the growth of harmful microorganisms. Monitoring temperatures regularly ensures that all products are safe for consumption, preventing foodborne illnesses.

Common Mistakes in Food Handling

In any culinary environment, there are several key areas where mistakes are often made, leading to potential health risks. These errors can occur at any stage of preparation or service, from storing ingredients to serving meals. Recognizing and correcting these mistakes is essential for maintaining a safe and clean environment for both workers and customers.

One of the most frequent issues is improper storage, where items are not kept at the correct temperature or are placed in unsanitary conditions. Another common mistake is cross-contamination, which occurs when harmful bacteria spread from raw ingredients to ready-to-eat items. Additionally, failing to maintain proper personal hygiene, such as not washing hands regularly or wearing appropriate protective gear, is a critical mistake that can easily lead to contamination.

Finally, neglecting to regularly clean and sanitize surfaces and equipment can contribute to the spread of pathogens. Ensuring that all areas are properly cleaned and that tools are disinfected after each use is crucial in preventing harmful buildup. By being mindful of these mistakes and implementing best practices, workers can significantly reduce health risks in the workplace.

Key Principles of Safe Food Practices

Ensuring the well-being of customers and staff relies on the consistent application of essential safety principles. From the initial stages of preparation to the final steps of serving, each action taken in the kitchen should align with established best practices to prevent contamination and maintain hygiene. A deep understanding of these core principles is necessary for anyone working with consumables.

One fundamental aspect is maintaining the proper temperature for ingredients at every stage of handling. This includes keeping perishables cold to prevent bacterial growth and cooking items to the correct internal temperatures. Equally important is the prevention of cross-contamination, which can occur when harmful microorganisms are transferred from raw materials to ready-to-eat items. Proper storage, segregation, and careful handling can mitigate these risks effectively.

Personal hygiene plays a critical role in safe practices. Regular handwashing, wearing appropriate protective gear, and avoiding contact with ready-to-eat items directly with hands are all essential actions. Additionally, ensuring that work surfaces and tools are cleaned and sanitized frequently reduces the potential for harmful bacteria to thrive. By following these key principles, workers can contribute to a safe and healthy environment for everyone involved.

How to Prevent Cross-Contamination

Cross-contamination is one of the leading causes of foodborne illnesses, and it can occur at any point during the handling process. To maintain a safe environment, it’s essential to understand how contaminants can spread and take steps to prevent it. By implementing a few straightforward practices, workers can reduce the risk of transferring harmful microorganisms from one surface, item, or ingredient to another.

The first step in preventing cross-contamination is proper storage. Keep raw ingredients separate from items that are ready to be consumed. This reduces the chance of bacteria from raw meat, for example, contaminating fruits, vegetables, or prepared dishes.

- Store raw meats on the lowest shelves in refrigerators to prevent drips or spills onto other foods.

- Use color-coded cutting boards to designate specific surfaces for different types of ingredients, such as raw meats, vegetables, and dairy.

Next, thorough cleaning is essential. All surfaces and tools must be sanitized regularly to prevent buildup of harmful bacteria. This includes counters, knives, and other utensils used in food preparation.

- Wipe down surfaces before and after every use.

- Sanitize knives, cutting boards, and any other equipment after handling raw ingredients.

Lastly, proper hand hygiene cannot be overlooked. Hands should be washed frequently, especially after handling raw items or touching potentially contaminated surfaces.

- Wash hands with soap and warm water for at least 20 seconds after touching raw ingredients.

- Always dry hands with a clean towel or disposable paper towel to avoid re-contaminating surfaces.

By following these guidelines, the risk of cross-contamination can be significantly minimized, ensuring a safer environment for everyone involved.

Personal Hygiene Guidelines for Handlers

Maintaining high standards of cleanliness and hygiene is essential for anyone working in an environment where consumables are prepared, handled, or served. Proper personal care not only prevents contamination but also ensures that harmful bacteria and viruses do not transfer from the worker to the items being handled. Adhering to strict hygiene protocols is a critical component of safety in every aspect of the workplace.

Frequent handwashing is one of the most important practices. Hands should be washed with soap and warm water for at least 20 seconds, especially after touching raw ingredients, using the restroom, or handling waste. It is essential to ensure that hands are completely dry afterward using a clean towel or disposable paper towel to avoid transferring contaminants.

Protective clothing such as gloves, aprons, and hairnets also play a vital role in preventing contamination. Gloves should be changed regularly, particularly when switching tasks or handling different items. Aprons should be kept clean and free from contaminants, and hair should be properly covered to avoid hair from falling into the work area.

When to avoid working is another important aspect of personal hygiene. Workers should refrain from handling items if they are ill or showing signs of a contagious condition. This includes symptoms like coughing, sneezing, or having open wounds. In such cases, workers should stay home to prevent the spread of germs.

By following these hygiene guidelines, workers contribute significantly to creating a safe and sanitary environment for both their colleagues and customers.

Temperature Control and Food Safety

Proper temperature control is essential in maintaining a safe environment where consumables are prepared and served. Temperature influences the growth of harmful microorganisms that can cause illness. Keeping ingredients and prepared items at the correct temperatures prevents bacteria from thriving and ensures that meals are safe for consumption.

There are two key temperature zones to be aware of: the danger zone and the safe zone. The danger zone is the temperature range where bacteria multiply rapidly, typically between 40°F (4°C) and 140°F (60°C). Keeping items out of this range significantly reduces the risk of contamination.

- Keep refrigerated items below 40°F (4°C) to prevent bacterial growth.

- Hot foods should be maintained at temperatures above 140°F (60°C) to keep them safe.

Additionally, it’s crucial to monitor internal temperatures when cooking, as certain items require specific cooking temperatures to kill harmful pathogens.

- Cook poultry to an internal temperature of at least 165°F (74°C).

- Cook ground meats to at least 160°F (71°C).

- Cook seafood to a minimum of 145°F (63°C).

By consistently monitoring and controlling temperature, workers can ensure that the environment remains free from harmful bacteria, making it safe for all individuals involved.

Importance of Proper Food Storage

Effective storage techniques play a critical role in maintaining the safety and quality of ingredients and prepared items. Proper storage helps preserve freshness, prevent spoilage, and protect against contamination, ensuring that everything remains safe for consumption. Without the right methods, harmful bacteria can thrive, leading to potential health risks.

Temperature and Storage Zones

Temperature control is a fundamental aspect of proper storage. Items that require refrigeration should be kept at or below 40°F (4°C) to slow bacterial growth. On the other hand, hot items should be stored at temperatures above 140°F (60°C) to prevent the development of harmful pathogens. Properly labeling storage units with clear temperature guidelines ensures that items remain in the correct conditions.

Segregation and Organization

Another key aspect is the proper organization of storage spaces. Raw ingredients, especially meats and seafood, should always be stored separately from ready-to-eat items to prevent cross-contamination. Using color-coded containers or clear labels can help workers easily identify and segregate items according to their storage requirements.

By following these practices, workers can greatly reduce the risk of contamination, spoilage, and potential foodborne illnesses, ensuring a safe environment for both staff and customers.

Identifying Common Foodborne Illnesses

Understanding and recognizing the signs of common illnesses caused by contaminated items is crucial for preventing outbreaks. These illnesses can range from mild discomfort to severe health complications, and knowing how to identify them early on is essential in maintaining a safe environment. The most common types of illnesses stem from bacteria, viruses, or parasites that contaminate ingredients during preparation or handling.

Symptoms of Common Illnesses

Common symptoms of contamination often include nausea, vomiting, diarrhea, and stomach cramps. Some illnesses may also cause fever, dehydration, or headaches, which can indicate more severe conditions. It’s essential to monitor these symptoms and take appropriate action to prevent the spread of the illness.

- Salmonella: Causes fever, diarrhea, and abdominal cramps, typically after consuming undercooked poultry or eggs.

- E. coli: Leads to severe stomach cramps, diarrhea, and vomiting, often linked to raw or undercooked beef.

- Norovirus: Highly contagious, causing vomiting, diarrhea, and stomach pain, frequently associated with contaminated water or produce.

Prevention Methods

Preventing these illnesses involves proper hygiene practices, temperature control, and safe ingredient handling. Ensuring that all items are stored at the correct temperature, thoroughly cooked, and separated during preparation can significantly reduce the risk of contamination.

- Ensure that all meats are cooked to the recommended internal temperatures.

- Wash hands and surfaces frequently to prevent cross-contamination.

- Avoid consuming raw or undercooked items that are particularly prone to contamination.

By recognizing the symptoms of common illnesses and following safe practices, workers can help protect themselves and others from the dangers of contaminated items.

Best Practices for Cleaning and Sanitizing

Maintaining cleanliness and hygiene in preparation areas is essential for preventing contamination and ensuring the safety of consumables. Proper cleaning and sanitizing go hand-in-hand to eliminate dirt, bacteria, and other harmful microorganisms. Effective practices can significantly reduce the risk of illness and promote a safer environment for everyone involved in handling consumables.

The first step in any cleaning process is to remove visible dirt and debris. This can be done using hot water and detergent to scrub surfaces, tools, and equipment. Once the area is visibly clean, sanitizing agents should be applied to kill any remaining harmful pathogens that may not be visible to the eye.

Key practices for effective cleaning and sanitizing include:

- Ensure that cleaning agents are appropriate for the surfaces being cleaned, and follow the manufacturer’s instructions for proper dilution and use.

- Sanitize all high-touch areas, such as countertops, handles, and kitchen equipment, to eliminate any remaining harmful microorganisms.

- Regularly clean and sanitize floors, storage areas, and waste disposal bins to avoid cross-contamination.

- Maintain separate cleaning tools for different areas to prevent cross-contamination between preparation, waste, and storage zones.

- Properly train staff on the importance of frequent and thorough cleaning to ensure consistency and reliability in hygiene practices.

By integrating these best practices into everyday routines, facilities can minimize the risk of contamination and create a healthier environment for staff and customers alike.

Legal Requirements for Food Handlers

There are several legal regulations and standards in place to ensure that individuals working in environments where consumables are prepared and served maintain high levels of hygiene and safety. These laws are designed to protect consumers from potential health risks and to promote a clean and safe working environment. Complying with these legal requirements is essential for businesses to operate legally and effectively.

These regulations cover a wide range of practices, including proper sanitation, temperature control, and health screening for workers. It is important for employees to understand their responsibilities, as failing to comply with these laws can result in penalties, fines, or even the closure of the establishment.

| Regulation | Description | Requirement |

|---|---|---|

| Health and Hygiene Standards | Ensures employees maintain proper hygiene to avoid contamination. | Employees must wash hands regularly, wear protective gear, and be free from illness. |

| Temperature Control | Regulates the proper storage and cooking temperatures of ingredients. | Items must be stored at the right temperatures to prevent bacterial growth. |

| Training and Certification | Ensures that employees are trained in safe practices. | Staff must undergo training and certification to work in high-risk areas. |

| Inspection and Compliance | Ensures regular inspection of the premises and compliance with regulations. | Businesses must pass health inspections and comply with local food safety laws. |

Understanding these legal obligations is critical for maintaining a safe and lawful working environment. Businesses must ensure their employees are well-informed and that they adhere to the necessary hygiene and safety standards to prevent violations and promote consumer trust.

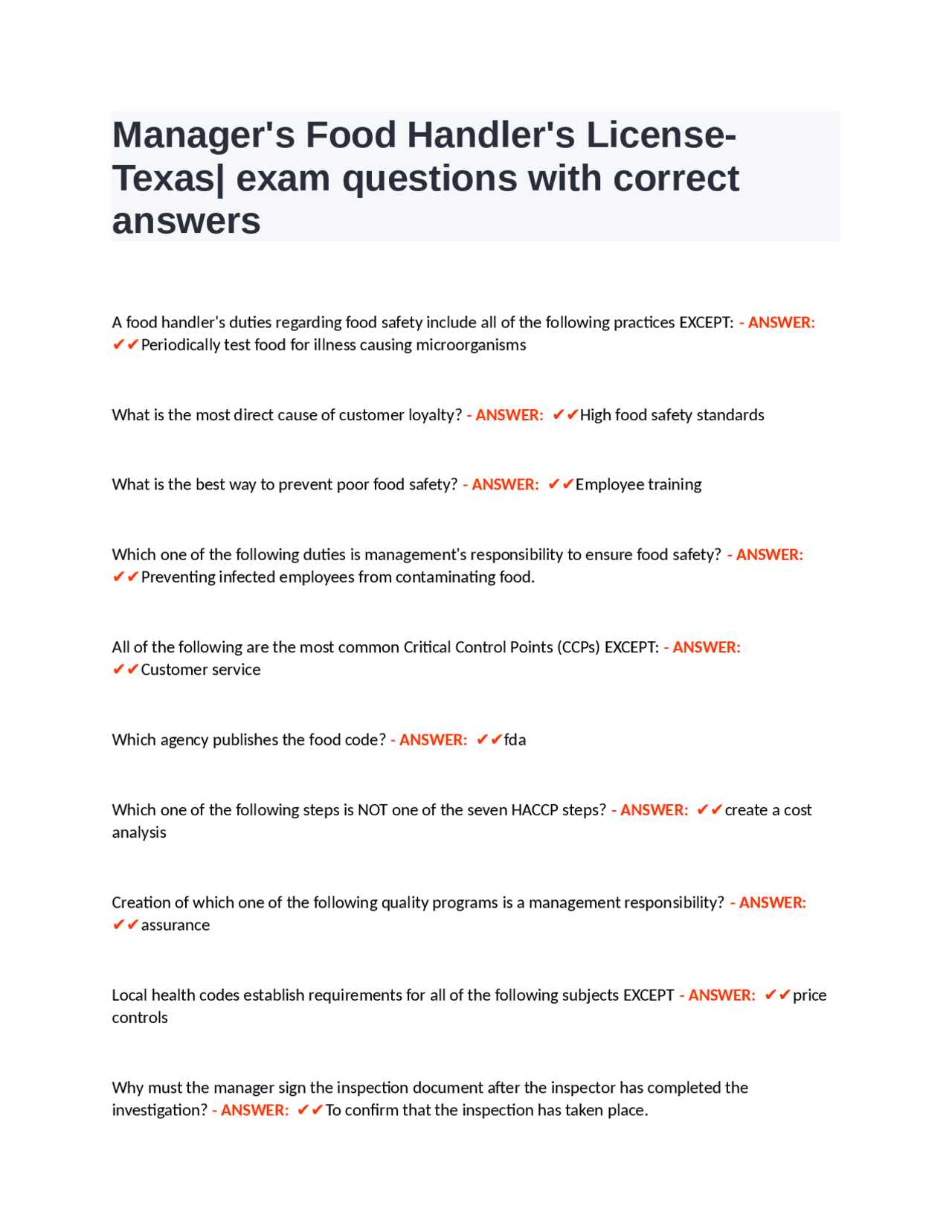

Understanding Food Handling Certifications

Certifications for individuals working with consumables are essential for ensuring that proper safety protocols are followed. These qualifications demonstrate that workers have the necessary knowledge and skills to handle items safely and hygienically. Various types of certifications exist, each targeting specific aspects of safe practices, from temperature control to preventing contamination. Understanding these certifications and their requirements is vital for anyone seeking to work in environments where safety standards are paramount.

Types of Certifications

There are different certification programs tailored to specific roles and responsibilities. Some focus on general sanitation practices, while others may concentrate on specialized areas like handling hazardous materials or managing allergens. The most recognized certifications are typically offered by national or local regulatory agencies, ensuring that they meet industry standards.

- Basic Safety Certification: This is often the first level of certification, covering general hygiene, cleaning procedures, and safe handling techniques.

- Advanced Safety Certification: A more in-depth program that includes training on foodborne illnesses, cross-contamination, and risk management.

- Specialized Certifications: These may focus on specific practices such as allergen management or handling specific types of consumables.

Benefits of Certification

Obtaining a certification not only ensures compliance with regulations but also demonstrates a commitment to high safety standards. It can increase job opportunities and improve overall workplace safety. For businesses, having certified employees is a sign of professionalism and can help reduce the risk of contamination and potential legal issues.

By understanding the different types of certifications and their relevance, workers and employers can make informed decisions that contribute to a safer, more reliable environment.

How to Pass the Safer Food Exam

Successfully completing a certification assessment in safe practices is an important step for anyone working in environments where consumables are prepared, served, or stored. The process can seem daunting, but with proper preparation and understanding of key principles, achieving a passing score is very attainable. This section will provide practical tips and strategies to help you prepare effectively and increase your chances of success.

One of the first things to focus on is familiarizing yourself with the key topics that will be tested. These often include hygiene protocols, preventing contamination, proper temperature control, and safe storage methods. Understanding these areas is crucial, as they form the foundation of safe practices in any setting. It is important to study the material thoroughly, paying attention to both theoretical knowledge and practical applications.

Here are some tips to help you succeed:

- Study the Core Principles: Ensure you understand the basics of sanitation, personal hygiene, and food safety regulations. The more familiar you are with these concepts, the more confident you will be during the assessment.

- Take Practice Tests: Many preparation programs offer practice assessments. Completing these can help you identify areas where you may need further study and become more comfortable with the format of the actual test.

- Stay Calm and Focused: During the actual assessment, it’s important to remain calm and read each question carefully. Time management is key, so pace yourself and make sure to address each section of the test thoroughly.

By following these strategies, you’ll be better prepared to demonstrate your knowledge and successfully pass the certification process. With preparation and focus, you can confidently navigate the assessment and take the next step in ensuring a safe environment for all involved.

Exam Preparation Tips and Strategies

Preparing for a certification assessment that evaluates your knowledge of safe practices requires focused effort and strategic planning. The key to success lies in understanding the main concepts and developing an effective study routine. With the right approach, you can boost your confidence and increase your chances of performing well on the test. This section will explore valuable preparation strategies and tips to help you achieve your goal.

First, it is crucial to break down the study material into manageable sections. By focusing on one topic at a time, you will ensure a deeper understanding of the material. Take time to review the most important areas, such as hygiene standards, contamination prevention, and safe handling practices. These core topics form the foundation of the certification and will likely make up a significant portion of the assessment.

Here are some proven strategies to help you prepare:

- Create a Study Schedule: Plan a study schedule that allows for consistent review. Set aside specific times each day to focus on different topics, ensuring that you cover everything before the assessment date.

- Use Active Learning Techniques: Instead of just reading the material, engage with it actively. Take notes, create flashcards, and quiz yourself regularly to reinforce key concepts.

- Focus on Practice Questions: Completing practice questions is one of the most effective ways to prepare. This will familiarize you with the format of the test and help you identify areas where you may need to improve.

- Review the Test Guidelines: Familiarize yourself with the assessment format, including the types of questions (multiple choice, true/false, etc.) and the time constraints. Knowing what to expect can reduce test anxiety.

By applying these preparation strategies, you will be able to approach the assessment with confidence and demonstrate your knowledge effectively. Consistent study, practice, and understanding of key concepts are the foundation of successful certification completion.

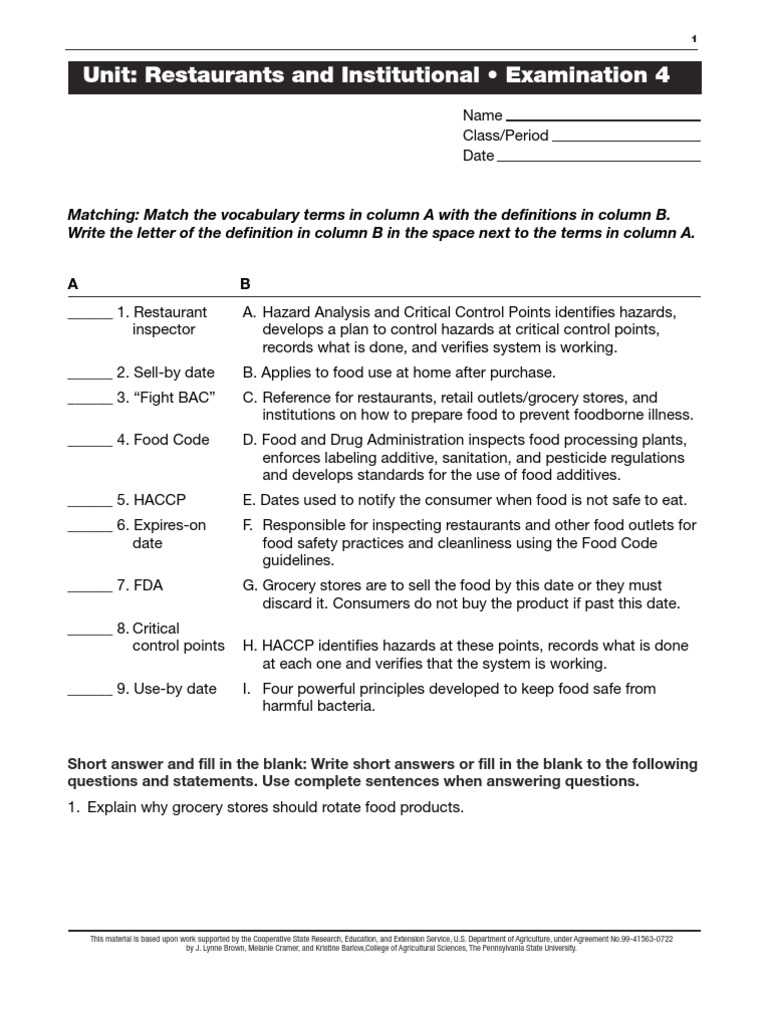

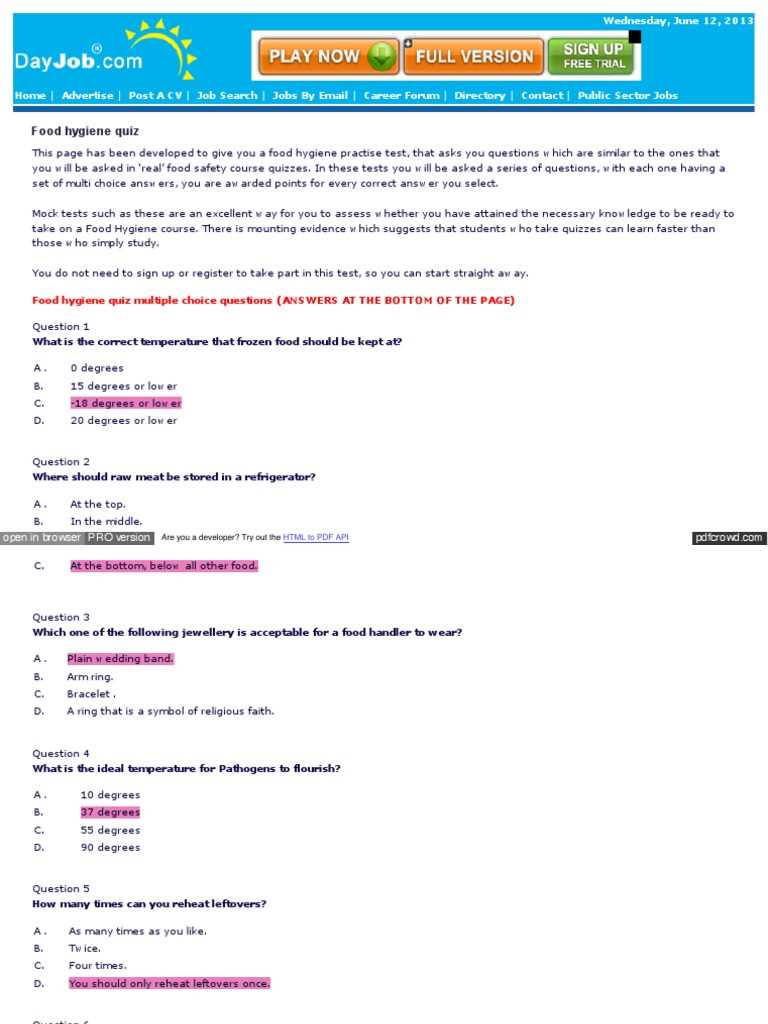

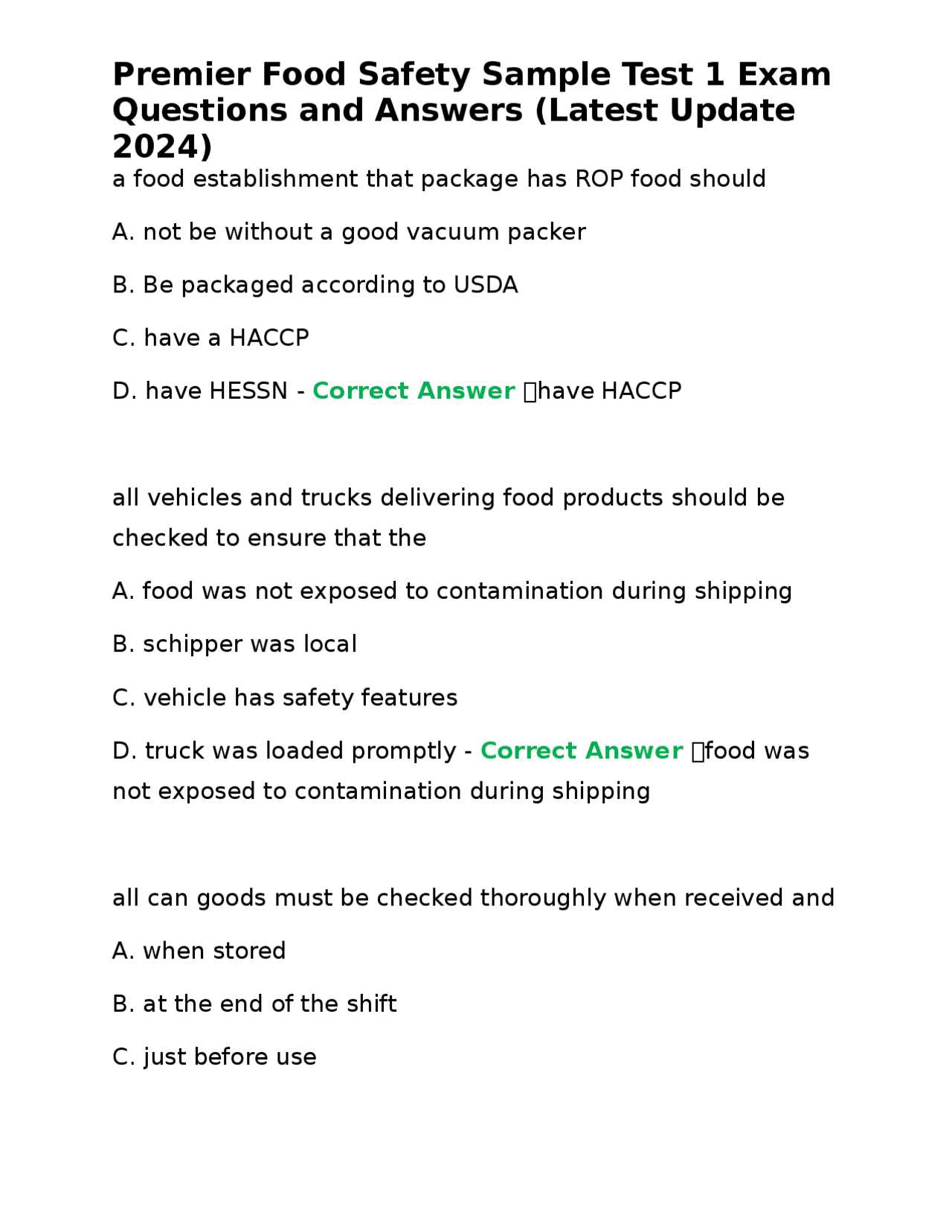

Test Questions You May Encounter

As you prepare for the certification assessment, it is helpful to familiarize yourself with the types of questions you may face. Understanding the format and style of questions will help you feel more confident and reduce test-day anxiety. The questions will primarily focus on essential concepts related to maintaining hygiene, preventing contamination, and adhering to safety protocols. In this section, we will explore common topics and provide examples of the types of questions you might encounter.

Below is a table with sample questions that you may see on the assessment. These examples cover a range of essential topics and demonstrate the focus areas of the certification process:

| Question | Answer Choices |

|---|---|

| What is the proper temperature for storing perishable items? |

|

| What is the best method for preventing cross-contamination? |

|

| How often should food contact surfaces be cleaned and sanitized? |

|

| Which of the following is a common symptom of foodborne illness? |

|

These sample questions are designed to test your knowledge of safety procedures and regulations. While the actual test may vary, the key areas of focus will remain consistent, including hygiene, contamination prevention, proper storage, and safe handling practices. Review these examples and practice answering similar questions to enhance your preparation.

How to Maintain Certification After Passing

Achieving certification in a safety-related field is a significant accomplishment, but it doesn’t end with passing the assessment. To ensure that your certification remains valid, it is essential to stay up-to-date with industry standards and maintain the knowledge required to perform duties effectively. This section outlines the steps you should take to preserve your certification and continue demonstrating proficiency in your role.

Maintaining certification typically involves the following key actions:

- Renewal Process: Most certifications require renewal every few years. Ensure you know the specific renewal timeline for your certification and begin the process well before it expires.

- Continuous Education: Engage in ongoing training to stay informed about new regulations, best practices, and emerging trends in the industry. Many certification bodies offer courses, workshops, and seminars to help you meet these requirements.

- Compliance with Standards: Stay informed about changes in local and national safety standards. Regularly review relevant materials to ensure you are following the latest guidelines.

- Practice and Application: Apply the principles learned during your certification regularly. Staying hands-on will help you reinforce your knowledge and skills, ensuring that you are always prepared for inspections or audits.

- Record Keeping: Maintain accurate records of any training sessions, courses, or updates you complete. These records may be required when renewing your certification or during compliance checks.

By taking these proactive steps, you can ensure that your certification remains valid and that you are always up-to-date on the best practices for maintaining a safe and compliant environment. Remember, certification is not just a one-time achievement; it is an ongoing commitment to excellence and responsibility in your field.