Understanding the critical measures for workplace safety is essential for anyone looking to ensure a secure environment in high-risk industries. The certification process involves learning how to effectively manage hazards and utilize safety equipment, preparing individuals for real-world scenarios where accidents can be prevented through proper training.

Proper preparation is key to mastering the required knowledge, and taking the right steps to study and understand safety practices can make all the difference. This section covers the necessary information that candidates need to excel, focusing on key concepts and techniques used to minimize risks in construction and industrial settings.

Safety training plays a crucial role in reducing accidents, and by focusing on the most important concepts, anyone can gain the expertise required to pass the certification assessment and apply it confidently in their work environment.

Workplace Safety Certification Preparation

Mastering the essential principles of safety standards is crucial for those looking to pass the required certification process for securing a workplace environment. This section will help you navigate the key topics and equip you with the necessary knowledge to succeed in safety-related assessments.

Core Concepts for Certification Success

To ensure a strong understanding of the safety measures, it’s important to focus on several key topics that are frequently covered in the certification process. These topics include:

- Identifying hazardous conditions and their prevention

- Proper use of safety equipment

- Procedures for emergency situations

- Responsibilities of workers and supervisors

Common Questions and Pitfalls

Many candidates struggle with certain concepts. To better prepare, consider these common areas where people often make mistakes:

- Incorrect understanding of safety gear usage

- Failure to recognize critical hazards in specific work environments

- Confusion over regulations and their applications

By addressing these potential pitfalls during your study process, you will be well-prepared to demonstrate your proficiency and pass the assessment with confidence.

Understanding Safety Regulations in the Workplace

In any industry where employees face potential hazards, understanding the legal framework and standards that govern safety is essential. Regulations are designed to minimize risks and ensure that workers are protected from common dangers associated with high-risk tasks. These rules are not only important for compliance but also crucial for creating a secure work environment.

Workplace guidelines outline the necessary steps to assess, mitigate, and monitor risks. By following these standards, organizations can ensure their workers are equipped with the knowledge and tools to work safely. Safety requirements often focus on specific tasks and environments, demanding that companies implement strategies tailored to prevent injuries and accidents.

Adherence to these regulations ensures that both employers and employees understand their roles in maintaining a secure environment. Familiarizing yourself with the specifics of these rules is key to avoiding accidents and fostering a culture of safety within any organization.

Key Safety Requirements for Workers

Ensuring worker safety involves a set of crucial guidelines that focus on reducing risks and preventing accidents. These requirements serve as a foundation for maintaining a secure and efficient workplace, especially in environments where hazards are prevalent. By following these standards, workers can perform their tasks confidently, knowing that their safety is prioritized.

Proper training and education are at the core of any safety protocol. Workers must be educated on how to recognize potential hazards and understand the correct usage of safety equipment. Additionally, they must be trained to follow emergency procedures in case of unforeseen events.

Personal protective equipment (PPE) is another critical aspect of safety requirements. Depending on the nature of the work, employees must wear appropriate gear such as helmets, gloves, or harnesses to protect themselves from injury. Ensuring that workers are equipped with the right PPE can significantly reduce the likelihood of accidents.

Finally, maintaining a safe working environment requires constant vigilance and adherence to safety procedures. Regular safety checks, equipment maintenance, and hazard assessments are necessary to identify and address any risks that may arise during daily operations.

Common Mistakes in Safety Certification Assessments

When preparing for a workplace safety certification, candidates often encounter certain challenges that can lead to mistakes during the assessment process. Understanding the common pitfalls can help improve performance and ensure a higher success rate. Recognizing these issues beforehand allows individuals to focus their study efforts and avoid costly errors.

| Common Mistake | Why It Happens | How to Avoid It |

|---|---|---|

| Misunderstanding safety procedures | Confusion over specific guidelines or regulations | Review and study the safety standards carefully, focusing on the correct protocols for each scenario. |

| Overlooking equipment usage | Lack of familiarity with the proper use of safety gear | Ensure practical understanding by practicing with the safety equipment and reviewing its correct application in real situations. |

| Failure to recognize hazards | Not identifying potential dangers in the work environment | Study common workplace hazards and the steps for mitigating them. Focus on hazard identification techniques. |

| Incorrect understanding of roles and responsibilities | Unclear distinction between worker and supervisor duties | Clarify the roles of each individual in safety protocols, making sure you know the responsibilities of all involved. |

Avoiding these common mistakes can significantly improve your chances of passing the certification and applying the safety knowledge effectively in the workplace. Focus on thorough preparation and understanding key concepts to excel in your assessment.

Top Safety Equipment Explained

Ensuring worker safety requires the use of reliable and effective equipment designed to minimize risks in hazardous environments. Understanding the different types of safety gear and how to use them properly is essential for maintaining a secure workplace. The following section highlights some of the most commonly used equipment for preventing injuries in high-risk jobs.

Essential Safety Gear for Workers

The right equipment can make all the difference in preventing accidents. Here are some key items that every worker should be familiar with:

- Harnesses: Used to secure workers to an anchor point, preventing falls from heights.

- Guardrails: Installed along edges to create a barrier that keeps workers from stepping too close to dangerous areas.

- Lifelines: Flexible lines that workers are connected to, providing additional support in case of a slip or misstep.

- Anchor Points: Fixed structures to which safety equipment such as lanyards or harnesses are attached.

- Shock Absorbers: Devices attached to lanyards or lines that reduce the impact of a fall by slowing the descent.

Understanding Proper Use of Equipment

Proper use and maintenance of safety gear are crucial to ensure its effectiveness. Workers should:

- Inspect equipment before each use to check for wear and tear.

- Follow all manufacturer guidelines for fitting and use.

- Ensure that gear is properly adjusted to fit the worker’s body size and job requirements.

By using the right equipment and following safety protocols, workers can significantly reduce the risk of injury while performing tasks in high-risk environments.

How to Pass Workplace Safety Certification Easily

Successfully completing a workplace safety certification can significantly enhance your qualifications and ensure that you are well-prepared to handle risks in hazardous environments. To pass the certification with ease, it’s important to focus on the core concepts and understand the practical applications of safety protocols. This guide will outline some strategies that will help you achieve success in the assessment process.

Focus on Key Safety Concepts

Start by reviewing the most important topics that are frequently covered in the certification process. Key areas to focus on include:

- Risk assessment techniques: Learn how to identify potential hazards and evaluate the severity of different risks.

- Safety equipment usage: Understand the proper usage, maintenance, and inspection of safety gear such as harnesses, ropes, and barriers.

- Emergency response procedures: Familiarize yourself with the steps to take in case of an accident or injury at the workplace.

Study Efficiently and Stay Consistent

Effective study habits can make all the difference. Break down the material into smaller sections and study consistently over time. Use resources such as practice quizzes, online courses, and videos to reinforce your understanding. Regular review is essential to retain critical information and avoid cramming at the last minute.

By focusing on these key areas and maintaining a disciplined study routine, you can pass the certification process confidently and with ease. Remember, understanding the material is more important than memorizing it – focus on practical knowledge that you can apply on the job.

Practical Tips for Safety Certification Success

Achieving success in a safety certification assessment requires more than just knowing the material – it involves adopting strategies that maximize your preparation and performance. This section offers practical advice that can help streamline your study process and improve your chances of passing the certification with confidence.

Effective Study Techniques

Successful preparation begins with understanding how to study efficiently. Here are a few practical tips:

- Set a study schedule: Break down the material into manageable sections and study regularly. Consistency is key to retaining information.

- Practice with quizzes: Take practice quizzes or mock tests to familiarize yourself with the question format and identify areas that need further attention.

- Focus on key topics: Concentrate your efforts on the most critical safety concepts and regulations that are commonly tested in the assessment.

Maximize Your Learning Resources

Utilize various learning tools to enhance your understanding of the subject. These resources can be extremely helpful:

- Online courses: Many online platforms offer interactive lessons that break down complex topics into easy-to-understand modules.

- Videos and demonstrations: Watch videos that show real-life applications of safety protocols to reinforce your theoretical knowledge with practical examples.

- Study groups: Join study groups to discuss concepts with others, exchange insights, and clarify doubts.

By incorporating these strategies into your preparation, you’ll be well-equipped to approach the safety certification assessment with a clear understanding of the material and confidence in your ability to succeed.

Understanding Hazards in Construction

In construction environments, workers face a variety of risks that can lead to serious injuries or fatalities. One of the most significant dangers involves the potential for workers to lose their balance or stability, often resulting in falls from great heights or uneven surfaces. Recognizing and understanding these hazards is essential for ensuring the safety and well-being of all personnel on site.

There are several key factors that contribute to risks in construction environments. The following are common scenarios that pose a danger to workers:

- Unprotected edges: Open edges or incomplete structures without guardrails or barriers increase the risk of accidental falls.

- Slippery surfaces: Wet, icy, or greasy surfaces can cause workers to lose their footing, especially in areas with high foot traffic.

- Improperly secured ladders: Ladders that are not firmly placed or used incorrectly can lead to dangerous falls from height.

- Cluttered work areas: Obstacles, tools, and materials left on the ground can create tripping hazards and increase the likelihood of slips or falls.

- Faulty scaffolding: Inadequately assembled or maintained scaffolding can collapse or shift, putting workers at great risk of injury.

Understanding these hazards is just the first step in creating a safer work environment. It’s crucial that construction workers are trained to identify, prevent, and respond to these dangers appropriately, ensuring that proper precautions are always in place.

Types of Safety Systems for Workers

In high-risk environments, it is essential to implement various systems designed to prevent accidents and minimize injury in case of a slip or misstep. These systems are designed to support workers, helping them stay safe while performing tasks at elevated heights or in precarious positions. Below are some common types of safety systems that are used to safeguard workers from dangerous situations.

Personal Fall Arrest Systems

Personal safety systems are designed to catch workers if they lose their balance or stability while working at heights. These systems typically include the following components:

- Harness: A device worn by the worker that is connected to an anchor point, designed to distribute the forces in case of a fall.

- Lanyard: A flexible line that connects the worker’s harness to an anchor point, allowing some movement but restricting a fall.

- Anchor Point: A secure attachment point, such as a beam or a structural component, to which the lanyard or harness is connected.

Guardrail Systems

Guardrails are barriers installed along edges to prevent workers from accidentally stepping or falling off. They are commonly used on rooftops, scaffolds, and other elevated platforms. Key features of guardrail systems include:

- Top Rail: A horizontal rail that serves as the primary barrier and is typically set at a height that prevents workers from falling over.

- Mid Rail: A secondary barrier placed between the top rail and the walking surface to prevent falls.

- Toeboards: Installed at the bottom of the guardrail to prevent tools, materials, or debris from falling and posing a risk to workers below.

These safety systems are essential for protecting workers from the risks of working at height, ensuring that all possible hazards are addressed with proper equipment and practices.

Importance of Personal Safety Systems

In high-risk environments where workers perform tasks at significant heights or near hazardous areas, personal safety systems play a critical role in ensuring their well-being. These systems are specifically designed to provide immediate safety in case of accidents, minimizing the likelihood of severe injury or fatalities. The proper use of these systems can mean the difference between life and death, especially in situations where other protective measures may not be sufficient.

Personal safety systems are essential because they help workers remain safe even if they lose their balance or make a misstep. These systems are engineered to reduce the impact of a fall by distributing forces across the body and limiting the distance a person can drop. By using these devices, workers can have more confidence while performing tasks that involve significant risk.

Key Elements of Personal Safety Systems

Personal safety systems consist of several components that work together to ensure maximum protection. Understanding these parts is crucial for effective use:

| Component | Description |

|---|---|

| Harness | A wearable device that secures the worker, connecting them to the safety system and reducing the impact during a fall. |

| Lanyard | A flexible rope or cable that links the harness to a secure anchor point, allowing for movement while preventing free falls. |

| Anchor Point | A fixed point that provides a stable attachment for the lanyard or harness, ensuring the worker’s safety in case of a fall. |

By using a well-designed personal safety system, workers can significantly reduce the risk of injury from falls. Proper training and regular equipment inspection are also vital to ensuring the system performs as intended. These systems are not just optional; they are a vital part of any safety program aimed at protecting workers from serious accidents on the job.

Proper Ladder and Scaffold Safety

Working at height requires strict safety measures to prevent accidents and injuries. Ladders and scaffolds are essential tools for workers who need to access elevated areas, but if not used correctly, they can become significant hazards. It’s crucial to follow established guidelines and implement the right practices to ensure these tools provide secure and stable access to high places without compromising worker safety.

Ladder Safety Guidelines

When using ladders, there are several key factors to consider to ensure they are both safe and effective. Here are some important safety tips:

- Inspect Before Use: Always check the ladder for any signs of damage, such as cracks or loose rungs, before use.

- Set on Stable Ground: Ensure that the ladder is placed on level, stable ground to prevent it from tipping over.

- Maintain 3 Points of Contact: When climbing, always maintain three points of contact with the ladder–two hands and one foot, or two feet and one hand.

- Never Overreach: Keep your body centered on the ladder and avoid leaning too far to one side, as this could cause a loss of balance.

- Use the Right Ladder: Select a ladder that is appropriate for the task and height required, ensuring it can support the weight of the worker and any tools or materials.

Scaffold Safety Guidelines

Scaffolding is often used for longer-term elevated work. To ensure safety while using scaffolds, follow these essential practices:

- Ensure Proper Assembly: Only trained personnel should assemble and dismantle scaffolding to ensure it is correctly constructed.

- Guardrails and Toeboards: Always use guardrails, midrails, and toeboards on scaffolding to prevent falls and protect workers from falling objects.

- Check Stability: Before use, check that the scaffold is firmly anchored and that all legs are level.

- Limit Load Capacity: Be aware of the scaffold’s load limits and ensure it is not overloaded with materials or equipment.

- Use Safe Access: Always use proper ladders or stairways for access to scaffolding rather than climbing on the structure itself.

By adhering to these safety guidelines, workers can significantly reduce the risk of accidents and ensure a safer working environment while using ladders and scaffolds. Safety training and regular inspections are vital to maintaining these best practices and ensuring that all tools are used properly.

Role of Safety Training in Fall Prevention

Safety training is a vital element in creating a safe working environment, particularly in industries where employees are exposed to heights or other dangerous conditions. Effective training programs ensure that workers understand the risks associated with their tasks and know how to avoid accidents. Proper education on the correct use of equipment, procedures, and safety measures can drastically reduce the likelihood of injuries, even in high-risk environments.

Training provides workers with the knowledge and skills they need to identify potential hazards before they become serious problems. Through proper instruction, employees learn the importance of using personal safety equipment, setting up work areas securely, and following safe practices at all times. Moreover, regular safety sessions reinforce the importance of these practices and keep workers alert to new techniques or equipment that may improve their safety.

In addition to reducing accidents, safety training also fosters a culture of responsibility and awareness. When workers are equipped with the right information, they are more likely to act proactively in maintaining safety standards, not only for themselves but for their colleagues as well. This creates an overall safer environment and helps in reducing downtime caused by injuries or accidents, which can also have financial benefits for employers.

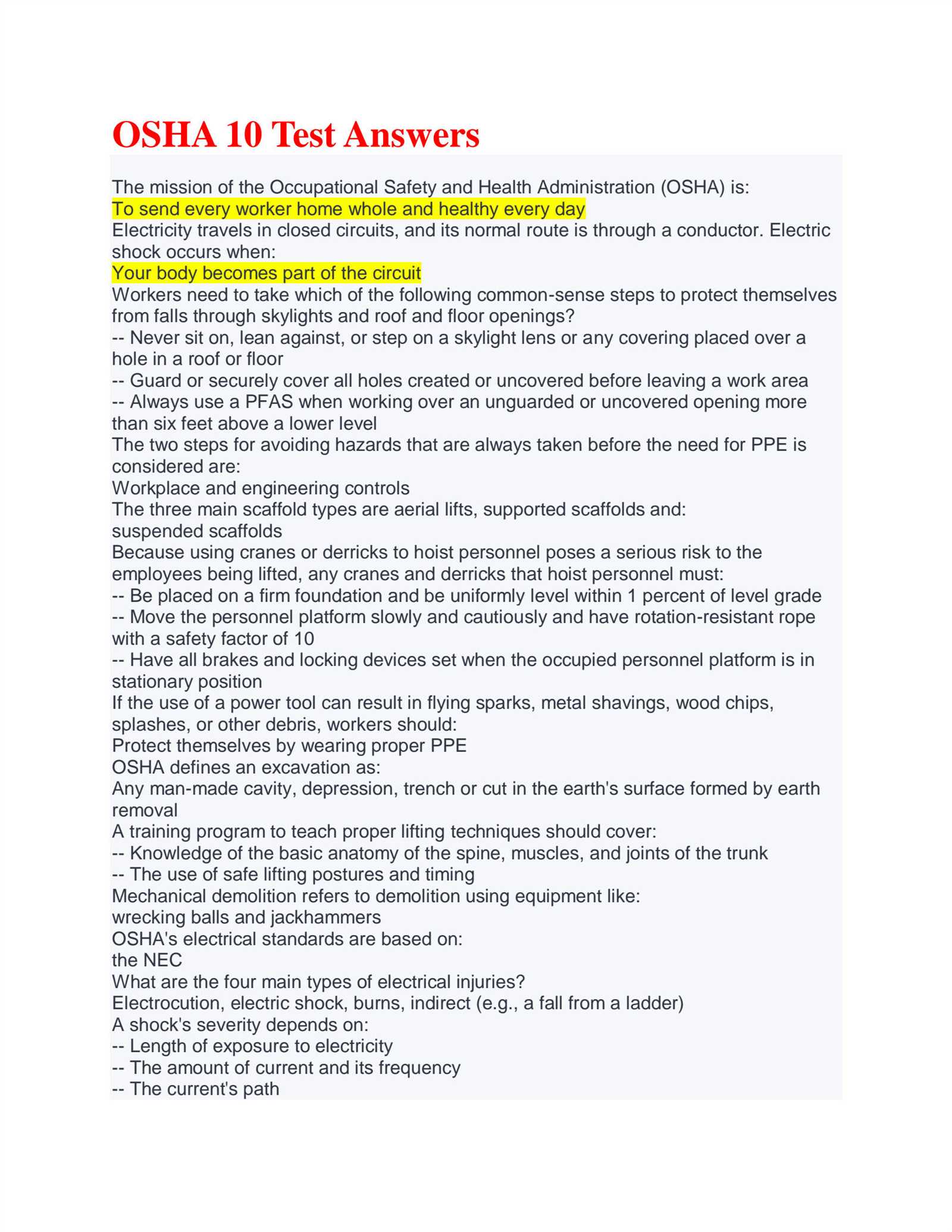

Frequently Asked Questions About Osha 10

There are many common questions regarding safety certification courses, especially for workers in high-risk environments. Understanding the essential details of these training programs can help employees prepare effectively and employers ensure their team is well-equipped to handle potential hazards. This section addresses some of the most frequently asked questions about safety certification courses that are designed to enhance knowledge of safe practices and procedures.

What is Covered in the Training?

Safety training programs generally cover a range of critical topics aimed at reducing workplace hazards. The key areas typically include:

- Risk Assessment: Identifying potential hazards and evaluating the level of risk.

- Correct Use of Safety Equipment: Understanding the proper use and maintenance of safety gear like harnesses, lanyards, and guardrails.

- Emergency Procedures: Learning how to react in case of an emergency, including first aid and evacuation plans.

- Worksite Safety Measures: Establishing protocols for maintaining a safe working environment, including proper signage and barrier placement.

How Long Does the Training Take?

The duration of safety training programs can vary depending on the course type and the delivery format. Most programs are designed to be completed within a few hours or over the span of a couple of days. However, the comprehensive nature of the content ensures that participants are well-prepared to handle the challenges they might face on the job.

Participants can typically expect a combination of online modules and in-person sessions, with opportunities for practical demonstrations and assessments to reinforce the learning process.

Real-Life Fall Protection Scenarios

In real-world workplaces, the risks associated with working at heights or in hazardous conditions are always present. To help reduce accidents, it’s essential to understand how safety measures apply in different scenarios. By examining common situations, workers can gain insights into the types of precautions they should take to minimize risk and ensure their well-being on the job.

Scenario 1: Construction Site – Working on Elevated Platforms

On construction sites, workers often find themselves working on elevated platforms such as scaffolds or roof edges. These areas present significant hazards if safety measures are not followed. In one scenario, a worker is performing tasks on a scaffold without proper restraint systems in place. The risk of a slip or accidental movement is high, leading to a potentially dangerous situation. To avoid this, it’s essential to ensure that proper barriers are in place, and that personal protective equipment such as harnesses and lanyards are securely fastened to designated anchor points.

Scenario 2: Warehouse – Use of Ladders

In warehouse settings, employees regularly use ladders to reach high shelves. A worker is tasked with retrieving items from an upper storage rack. Without proper safety equipment, this seemingly routine task can result in a fall. In this case, using a sturdy, properly placed ladder, and employing a safety harness or other equipment to prevent sudden shifts or slips, significantly reduces the chances of injury. It’s also crucial that workers are trained in proper ladder usage and aware of their surroundings to avoid unnecessary risks.

Certification and Career Benefits

Obtaining a certification in workplace safety can significantly enhance an individual’s career prospects. By demonstrating knowledge of safety protocols and risk mitigation strategies, workers not only increase their competence but also contribute to a safer working environment. This certification, which focuses on safety procedures and the proper use of safety equipment, is recognized across various industries, making it a valuable asset for employees and employers alike.

Enhanced Job Opportunities

One of the primary benefits of earning this certification is improved job opportunities. Many companies require their employees to undergo safety training as part of their onboarding process, especially in industries such as construction, manufacturing, and warehousing. Those who hold this certification are often prioritized for roles that involve higher risk or specialized safety equipment, as it demonstrates a commitment to both safety and professionalism.

Increased Earning Potential

Certification in workplace safety can also lead to increased earning potential. Employees with specialized knowledge in safety protocols may be eligible for higher-paying positions due to their ability to reduce risk and prevent accidents. Employers value workers who can not only perform their tasks efficiently but also help to ensure the safety of their colleagues, making these certifications a worthwhile investment for career growth.

Building a Reputation as a Safety Leader

Holding a safety certification can also position individuals as leaders in workplace safety initiatives. With an understanding of key safety regulations and best practices, certified workers can serve as role models for their peers, promoting safety awareness and ensuring compliance with industry standards. This can lead to leadership opportunities and long-term career advancement.

How to Study for Safety Certification

Preparing for a safety certification assessment involves understanding key concepts related to workplace safety standards, hazard identification, and risk management. Effective study strategies can help you grasp essential guidelines and equip you with the necessary skills to pass the certification successfully. A focused approach can also ensure that you retain the information needed to apply it effectively in real-world scenarios.

Study Plan and Resources

Creating a structured study plan is crucial to cover all the relevant material in a timely manner. Break down the topics into manageable sections and allocate time for each. Use a variety of resources, such as manuals, online courses, and practice quizzes, to reinforce your knowledge. Here’s an outline of key study topics:

| Topic | Description |

|---|---|

| Workplace Safety Guidelines | Understanding general workplace safety regulations and guidelines. |

| Risk Assessment | Identifying and assessing potential hazards in various work environments. |

| Safety Equipment | Learning about personal protective gear and its correct usage. |

| Emergency Procedures | Recognizing emergency response protocols and evacuation plans. |

Practical Application and Quizzes

Incorporating practice quizzes into your study routine can help reinforce key concepts and improve your test-taking skills. Many online platforms offer mock tests that simulate the real certification process. These quizzes can help you become familiar with the question format and identify areas that require further study. Additionally, consider reviewing case studies or real-life examples of safety measures in practice, as they can offer valuable insights and practical knowledge.

Consistency and Focus

Consistency is vital when preparing for a certification. Set aside regular study times and stick to your schedule. Stay focused by minimizing distractions and reviewing the material daily. With proper preparation and commitment, you will be well-equipped to succeed in your certification assessment.