Ensuring that personal protective equipment (PPE) is properly maintained is essential for the safety and effectiveness of firefighters. A key part of this process involves understanding and adhering to the regulations that govern the care and inspection of protective clothing and gear. Firefighters must be well-versed in these procedures to prevent equipment failure and ensure they are prepared for any emergency situation.

In this section, we will explore the steps required to become proficient in PPE care and certification. By following the established standards, firefighters can guarantee that their gear is up to code, properly cleaned, and functioning as intended. Understanding these protocols not only enhances safety but also boosts a firefighter’s readiness and confidence on the job.

Preparing for certification requires dedication, but the rewards are clear: reduced risk of accidents, compliance with industry standards, and the peace of mind that comes from knowing the equipment is in optimal condition. The process involves studying key maintenance techniques, recognizing when gear needs repair, and following best practices to extend the lifespan of essential protective equipment.

Firefighter Gear Maintenance Certification Overview

Certification in personal protective equipment (PPE) maintenance is a crucial step for ensuring the safety and efficiency of firefighting operations. The process is designed to verify that individuals understand the proper care, cleaning, and inspection protocols for protective gear. This knowledge not only guarantees compliance with industry standards but also plays a vital role in the protection of firefighters during hazardous situations.

Key Focus Areas

Understanding the maintenance procedures of firefighter gear requires familiarity with several important areas. These include:

- Inspection protocols: Regular checks to ensure gear remains free from damage and is fully functional.

- Cleaning standards: Methods to properly clean and decontaminate equipment to extend its lifespan and ensure safety.

- Repair guidelines: Recognizing when gear is in need of repairs and how to address issues effectively.

- Compliance with regulations: Adhering to legal and safety standards to maintain certification and operational readiness.

Benefits of Certification

Achieving proficiency in maintaining firefighter gear offers numerous benefits:

- Improved Safety: Properly maintained equipment reduces the risk of malfunction during critical operations.

- Enhanced Efficiency: Firefighters are better prepared to perform their duties with reliable and safe gear.

- Regulatory Compliance: Staying up to date with the latest standards ensures that teams meet industry and legal requirements.

By thoroughly understanding these areas, firefighters not only enhance their personal safety but also contribute to the overall effectiveness of their teams. Proper preparation and certification are essential in making sure the equipment remains reliable under the toughest conditions.

What is PPE Maintenance Certification

Certification in protective gear maintenance is a process that ensures individuals are knowledgeable about the proper care, inspection, and repair of firefighting equipment. This certification validates that firefighters and safety officers understand the necessary procedures to maintain gear at optimal safety standards, thus minimizing the risks associated with using damaged or improperly maintained protective wear.

Key Components of Certification

The certification process focuses on several critical aspects of gear management:

- Inspection Procedures: Proper techniques for identifying wear, damage, or contamination in protective clothing and equipment.

- Cleaning and Decontamination: Guidelines for maintaining the cleanliness of gear to prevent health hazards and extend its lifespan.

- Repair and Replacement: Understanding when to repair or replace equipment to ensure continuous safety and functionality.

- Documentation and Compliance: Keeping detailed records of inspections, maintenance, and repairs to meet industry standards and regulations.

Why Certification Matters

Obtaining certification is crucial for several reasons:

- Ensures Gear Longevity: Regular maintenance keeps gear in excellent condition, reducing the frequency of costly replacements.

- Enhances Safety: Well-maintained equipment provides maximum protection, reducing the risk of injury in dangerous situations.

- Meets Legal and Regulatory Standards: Certification ensures compliance with safety regulations, preventing legal and operational risks.

In summary, achieving certification in protective gear maintenance is essential for those responsible for the safety of firefighters. It guarantees that equipment remains functional, safe, and ready for use in emergency situations, providing peace of mind to both personnel and their teams.

Importance of Proper PPE Maintenance

Proper maintenance of personal protective equipment (PPE) is critical to ensuring the safety and effectiveness of those relying on it in hazardous environments. Regular inspection, cleaning, and repair help maintain the gear’s integrity and functionality, reducing the risk of equipment failure during critical moments. Firefighters, emergency responders, and other professionals rely on this gear to protect them from physical harm, environmental dangers, and potential contaminants.

Risks of Neglecting PPE Maintenance

Failure to properly maintain protective gear can lead to various risks, including:

| Risk | Consequences |

|---|---|

| Compromised Protection | Increased vulnerability to burns, cuts, and chemical exposure. |

| Decreased Durability | Shortened lifespan of PPE, leading to more frequent replacements. |

| Inaccurate Performance | PPE may fail to function optimally in high-risk conditions. |

| Legal and Compliance Issues | Failure to meet industry safety standards may result in penalties. |

Benefits of Consistent Maintenance

By regularly maintaining and inspecting PPE, professionals can ensure their gear performs as expected in emergencies. Some of the key benefits include:

- Enhanced Safety: Well-maintained gear offers maximum protection, reducing the risk of injury during critical tasks.

- Cost Savings: Extending the life of PPE reduces the need for costly replacements and repairs.

- Regulatory Compliance: Regular maintenance ensures that equipment meets the necessary safety standards and legal requirements.

In conclusion, maintaining protective gear is not only essential for safety but also for ensuring operational efficiency and compliance with industry regulations. Proper care of PPE is an investment in both personal and team safety in high-risk environments.

Key Topics in PPE Maintenance Certification

The certification process for maintaining firefighting protective gear focuses on several essential areas that ensure the safety and reliability of equipment. To successfully complete this certification, individuals must be well-versed in the procedures for inspecting, cleaning, and repairing personal protective equipment (PPE). Understanding these topics is vital for ensuring that gear performs optimally when needed most, reducing the risk of injury and maintaining compliance with safety regulations.

Essential Knowledge Areas

Here are some key topics covered in the certification process:

| Topic | Description |

|---|---|

| Inspection Procedures | Learning how to identify wear, damage, or contamination in PPE and ensure it remains functional. |

| Cleaning Methods | Understanding the correct techniques for cleaning gear to prevent contamination and extend its lifespan. |

| Repair and Replacement | Knowing when to repair or replace damaged gear to maintain its protective capabilities. |

| Safety Regulations | Familiarity with safety standards and regulatory requirements to ensure equipment meets legal requirements. |

| Record-Keeping | Documenting inspections, maintenance, and repairs to maintain accurate equipment history. |

Understanding Maintenance Standards

In addition to these core areas, it is essential to understand the standards for PPE maintenance that are mandated by regulatory bodies. These standards help ensure that gear is kept in optimal condition and ready for use in emergency situations. Consistent adherence to maintenance protocols reduces the risk of accidents and ensures that protective equipment meets the highest levels of safety and performance.

Mastering these topics will not only help achieve certification but also contribute to a safer working environment, where gear reliability is guaranteed in the most critical situations.

How to Prepare for the Certification

Preparing for a certification in protective gear maintenance requires a structured approach, focusing on key concepts and practical skills. To succeed, individuals must familiarize themselves with the core topics related to PPE care, including inspection, cleaning, and repair procedures. A thorough understanding of these areas ensures not only a passing score but also a deeper knowledge that will improve safety and effectiveness on the job.

Study the Core Concepts

Start by reviewing the primary topics that are typically covered in the certification process. These may include:

- Gear Inspection: Learn how to identify wear and tear, contamination, and other issues that could affect performance.

- Cleaning and Decontamination: Understand the recommended cleaning methods for different types of PPE to ensure longevity and safety.

- Repair Protocols: Study when and how to repair damaged gear to keep it operational and safe.

- Regulatory Guidelines: Familiarize yourself with the standards and legal requirements that govern the maintenance of firefighting gear.

Practical Preparation Tips

In addition to theoretical knowledge, hands-on practice is essential. Here’s how you can prepare practically:

- Practice Inspections: Perform mock inspections of gear to identify defects or wear, using real-life examples whenever possible.

- Work with Equipment: Gain experience handling and maintaining different types of PPE, including cleaning and repair tasks.

- Review Past Materials: Study previous guidelines and manuals to become familiar with the types of questions and scenarios you may encounter.

By focusing on both theoretical knowledge and practical skills, you will be well-prepared to successfully complete the certification process.

Common Questions on PPE Care

When it comes to the care and maintenance of personal protective equipment (PPE), many individuals have common questions regarding the best practices and protocols to follow. Ensuring that gear remains in top condition is essential for the safety and well-being of those who rely on it. Here are some of the frequently asked questions related to PPE care and maintenance.

How often should PPE be inspected?

The frequency of inspections depends on the type of gear and how often it is used. Generally, PPE should be inspected before each use to ensure it is free from damage, wear, or contamination. Regular checks, at least quarterly, are also recommended to maintain optimal functionality.

Can PPE be washed?

Yes, many types of PPE, such as helmets, gloves, and protective clothing, can be washed. However, it is important to follow the manufacturer’s guidelines for washing methods and to use the correct cleaning agents to avoid damaging the material or compromising its protective qualities.

What should I do if my PPE is damaged?

If PPE shows signs of damage, such as tears, burns, or missing components, it should be removed from service immediately. Depending on the damage, repairs may be possible, or the item may need to be replaced. Always refer to the manufacturer’s instructions on how to address such issues.

Is there a specific way to store PPE?

Yes, PPE should be stored in a clean, dry, and cool environment to prevent damage. Avoid exposing it to direct sunlight, extreme temperatures, or chemicals that could degrade the materials. Proper storage helps prolong the life of the gear and ensures it remains ready for use.

Can PPE be repaired?

Many types of PPE can be repaired, but it is important to follow the proper guidelines for each item. Small repairs, such as stitching or patching, can often be done, but if the protective performance is compromised, the gear should be replaced.

Understanding PPE Maintenance Standards

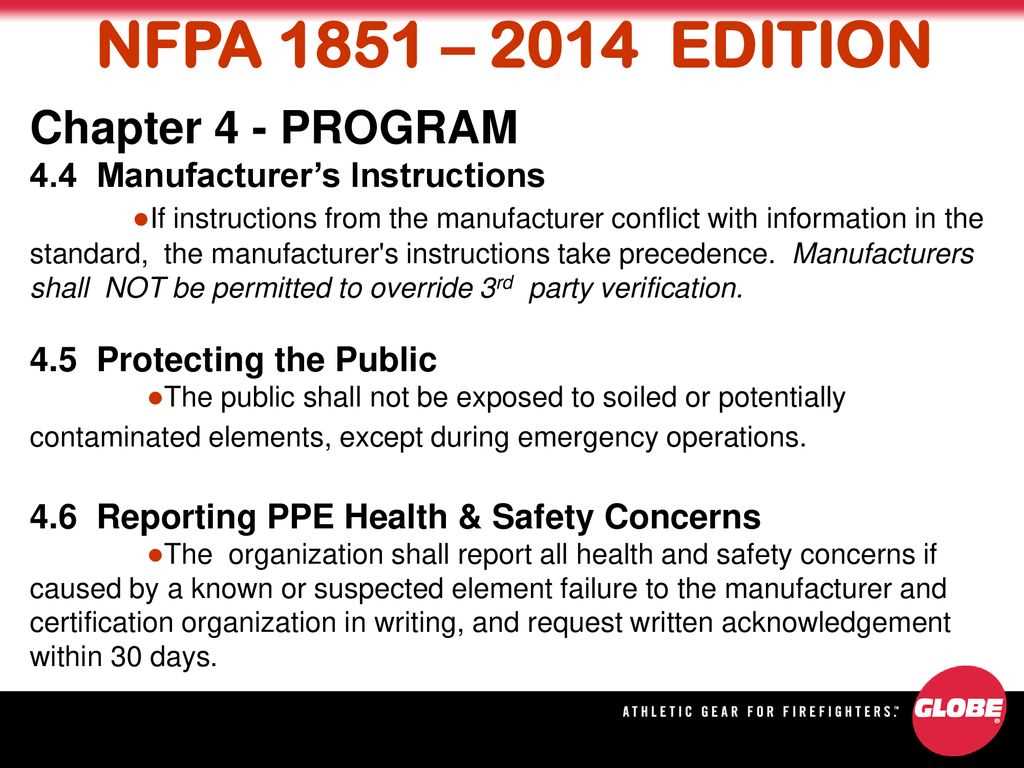

Maintaining protective gear according to established industry standards is crucial to ensuring the safety and effectiveness of the equipment. These standards outline the necessary procedures for inspecting, cleaning, and repairing gear to ensure it meets specific safety requirements. Adhering to these guidelines helps reduce the risk of equipment failure and ensures that the gear provides optimal protection during emergencies.

Understanding and following PPE maintenance standards involves recognizing the key elements that define the proper care of protective equipment. This includes understanding how often to inspect the gear, which methods of cleaning are appropriate, and when the gear needs to be replaced or repaired. Standards also cover the proper storage of PPE to prevent deterioration over time.

Compliance with these standards is not only a matter of safety but also a legal requirement in many industries. Failing to adhere to these protocols can result in non-compliance with safety regulations and could lead to legal liabilities or increased risk of injury.

By ensuring that protective gear is properly maintained and adheres to established standards, organizations can create a safer work environment for employees while extending the life of their protective equipment.

Examining Personal Protective Equipment Procedures

Effective maintenance of personal protective equipment (PPE) is a critical process that ensures the safety and reliability of gear used in hazardous environments. Proper procedures for inspecting, cleaning, and repairing PPE are essential for keeping it in optimal condition. Regular examination of gear not only helps identify potential hazards but also ensures that equipment meets safety standards required for maximum protection.

Inspection Procedures

The first step in maintaining protective gear is conducting thorough inspections. Regular checks should be performed to identify any signs of wear, damage, or contamination. Key areas to inspect include:

- Outer Shell: Look for abrasions, tears, or burn marks that may compromise the material’s integrity.

- Seams and Stitching: Ensure that stitching is intact and seams are not separating, which could lead to weakened areas.

- Reflective Trim: Check that reflective material is not damaged, as it is vital for visibility in low-light conditions.

- Straps and Closures: Examine straps, zippers, and other closures to make sure they function properly and are not broken or frayed.

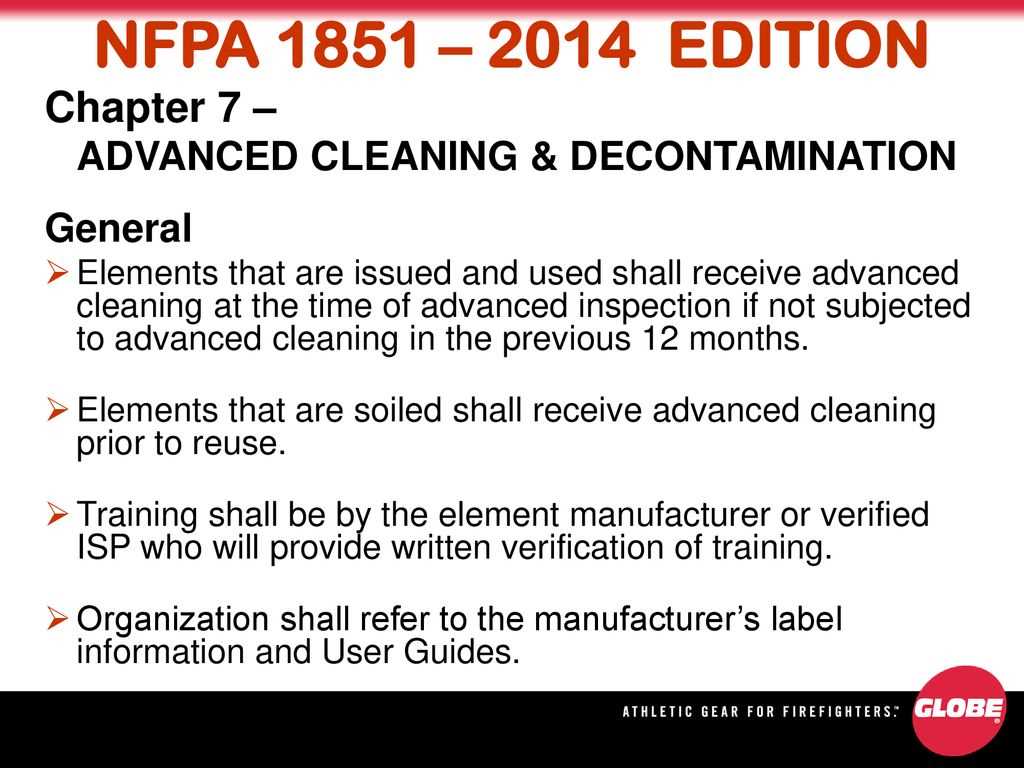

Cleaning and Maintenance Guidelines

Once inspections are complete, cleaning is the next essential procedure. PPE must be cleaned according to the manufacturer’s guidelines to ensure that it remains free from contaminants, while also preventing any damage to the materials. Proper cleaning can extend the life of the gear and help maintain its protective qualities.

- Cleaning Agents: Use only approved cleaning products to avoid damaging the fabric or compromising protective coatings.

- Drying Methods: Allow the gear to air dry away from direct heat sources to prevent material degradation.

- Storage: Store PPE in a clean, dry place to avoid exposure to harmful chemicals, extreme temperatures, or sunlight.

By following these examination and maintenance procedures, you ensure that PPE remains functional, safe, and reliable when needed most, ultimately reducing the risk of injury and maintaining compliance with safety standards.

Common Mistakes During the Certification Process

While preparing for a certification assessment, it’s common for individuals to make mistakes that could negatively impact their performance. These errors often stem from a lack of thorough preparation, misunderstanding key concepts, or rushing through certain sections of the test. Identifying these mistakes in advance can help prevent them and improve your chances of success.

Not Reviewing the Guidelines Thoroughly

One common mistake is not fully reviewing the guidelines or materials before attempting the assessment. Failing to understand the detailed procedures for inspecting, maintaining, or repairing equipment can result in missing key questions or providing incorrect answers. It’s crucial to study the instructions and the standards set by the relevant authorities to ensure a comprehensive understanding of what’s required.

Rushing Through the Questions

Another frequent error is rushing through the questions without taking the time to think through each one carefully. While time management is important, answering questions too quickly without fully understanding them can lead to mistakes. It’s advisable to take a moment to read each question thoroughly and consider all possible answers before making a decision.

Overlooking Practical Application

Many individuals focus solely on theoretical knowledge, neglecting the practical aspects of the subject. This can lead to difficulties when questions involve real-world scenarios or hands-on procedures. It’s essential to practice applying what you’ve learned in realistic situations to ensure that you can both recall information and use it effectively in practice.

Ignoring the Importance of Safety Standards

Failing to prioritize safety standards during the certification process can lead to critical mistakes. The safety and well-being of individuals rely on adherence to established protocols. It’s important to keep safety regulations in mind when answering questions, as these guidelines are often integral to the correct answer.

Avoiding these common mistakes will help you approach the certification process with greater confidence and increase your chances of success. Proper preparation and attention to detail are key to mastering the material and passing the assessment with flying colors.

Steps to Maintain Firefighter Gear

Proper maintenance of firefighter gear is essential for ensuring its effectiveness and durability in high-risk situations. Regular care and inspection can significantly extend the life of the equipment, improve safety, and ensure compliance with safety standards. Following a systematic maintenance routine is crucial to keep protective gear in optimal condition, ready for use in emergencies.

Step 1: Regular Inspection

The first step in maintaining firefighter gear is performing routine inspections. Regular checks help identify any potential weaknesses, wear, or damage that could compromise the safety of the equipment. Inspecting the gear should be done after every use, and special attention should be given to:

- Outer shell: Look for tears, burns, or abrasions that may reduce the protective capabilities.

- Seams and stitching: Ensure that all seams are intact and stitching is secure to prevent fabric from unraveling.

- Reflective trim: Check for damage or discoloration to ensure visibility in low-light environments.

Step 2: Cleaning and Decontamination

Cleaning and decontaminating firefighter gear is essential for maintaining its protective functions. Gear can accumulate harmful substances such as smoke, chemicals, and soot that may affect its integrity. Cleaning should be done following the manufacturer’s instructions to avoid damaging the fabric. The key points in cleaning include:

- Use appropriate cleaning agents: Only use detergents or products recommended for firefighter gear to avoid material degradation.

- Avoid heat drying: Dry gear at room temperature to prevent shrinkage or damage to the fabric and other components.

- Proper storage: Store gear in a clean, dry area to avoid contamination and environmental damage.

By maintaining a regular inspection and cleaning routine, firefighters can ensure that their gear remains effective and safe to use. Proper care is key to protecting those who protect others.

Best Study Resources for the Certification

Preparing for a certification assessment requires the right materials and resources to ensure a comprehensive understanding of the required knowledge. Having access to reliable and well-structured study guides, practice tests, and reference materials can make a significant difference in achieving success. Below are some of the best study resources to help you prepare effectively and with confidence.

Study Guides and Textbooks

One of the most valuable resources for preparing for any certification is a detailed study guide or textbook. These materials typically break down the key concepts, standards, and best practices that are essential for the test. Look for guides that are specifically tailored to the certification you are pursuing. Some popular resources include:

- Official Certification Manuals: These manuals are created by the governing bodies and often provide a thorough overview of the standards and guidelines you will need to understand.

- Comprehensive Textbooks: Books that focus on the technical aspects of the profession and cover both theoretical knowledge and practical applications.

Practice Tests and Quizzes

Practice tests are an excellent way to familiarize yourself with the types of questions you may encounter during the assessment. Taking these tests helps you assess your knowledge and identify areas where you may need further study. Many websites offer free or paid practice tests designed to simulate the real exam environment. Key benefits include:

- Timed Practice Sessions: Simulate exam conditions to improve time management skills and reduce test anxiety.

- Comprehensive Question Banks: Access a wide range of practice questions covering all aspects of the certification.

Online Courses and Tutorials

If you prefer a more structured approach to studying, online courses and tutorials are great resources. These often offer video lessons, quizzes, and interactive content to help reinforce your knowledge. Popular platforms include:

- Interactive Courses: Online learning platforms like Udemy or Coursera offer specialized courses designed for certification preparation.

- Webinars and Workshops: Many professionals and training centers offer live sessions that focus on specific topics related to the certification.

Discussion Forums and Study Groups

Engaging with others who are preparing for the same certification can be incredibly helpful. Study groups and online forums provide opportunities to ask questions, share resources, and learn from others’ experiences. Some popular platforms include:

- Online Forums: Websites such as Reddit or specialized forums allow users to discuss topics, share tips, and find study partners.

- Social Media Groups: Facebook or LinkedIn groups offer a community of individuals who are also working toward the certification.

By utilizing a combination of these study resources, you can approach the certification process with confidence and ensure that you are well-prepared for success.

How to Pass the Certification Test

Successfully passing a certification test requires a focused approach and effective preparation. The key to achieving a high score lies in understanding the material, practicing regularly, and managing your time efficiently during the assessment. By following a few strategic steps, you can enhance your chances of success and ensure you are fully prepared to meet the requirements of the certification.

Step 1: Understand the Requirements

Before diving into study materials, it is important to have a clear understanding of what is expected from the certification test. Familiarize yourself with the key topics, the structure of the test, and the specific standards you need to know. This will help you prioritize your study efforts and focus on the most relevant areas. Some essential steps to take include:

- Review the official guidelines: Ensure you are aware of the testing criteria and any prerequisites for the certification.

- Understand the format: Know whether the test is multiple-choice, practical, or a combination of both, as this will affect how you prepare.

- Identify key knowledge areas: Focus on the most critical topics that are likely to appear in the test, such as safety procedures, gear maintenance, and operational standards.

Step 2: Use Reliable Study Materials

Choosing the right study materials is crucial for effective preparation. High-quality resources will help you absorb the necessary information and reinforce key concepts. Here are some types of resources to consider:

- Official manuals and handbooks: These are often the best resources as they contain the most accurate and up-to-date information related to the certification.

- Practice tests: Taking practice tests allows you to familiarize yourself with the types of questions and conditions you will face during the actual test.

- Online courses and tutorials: Interactive learning platforms can help break down complex topics and provide video lessons for better understanding.

Step 3: Practice and Repetition

Repetition is key when it comes to passing any certification. The more you practice, the more confident you will feel during the test. Consider these tips to ensure you are prepared:

- Take timed practice tests: Simulating test conditions will help you manage your time effectively and reduce anxiety on the actual day.

- Review your mistakes: After completing practice tests, carefully go over incorrect answers and identify areas where you need further improvement.

- Consistent study sessions: Study in short, regular intervals to keep the material fresh and reinforce what you have learned.

By understanding the test format, using reliable study materials, and committing to regular practice, you can greatly increase your chances of passing the certification test. Stay focused and dedicated, and you will be well on your way to success.

Scoring and Results of the Certification Test

Understanding how a certification test is scored is crucial for test-takers as it helps them assess their performance and prepare accordingly. The scoring system is typically designed to evaluate both knowledge and practical application, ensuring that candidates meet the required standards. In this section, we’ll explore how scores are calculated, what to expect from the results, and how to interpret your performance.

How the Test is Scored

The scoring of a certification test is usually based on a combination of correct answers and demonstrated practical knowledge. Some tests use a point-based system, where each correct response or successfully completed task adds to your total score. Other tests may have a weighted scoring system, with more complex or critical topics carrying more points. Here’s a general breakdown of how scoring works:

- Multiple-choice and true/false questions: Typically scored based on correct responses, with incorrect answers resulting in no points or a penalty.

- Practical assessments: Evaluated on the successful completion of tasks according to established standards. Points are awarded for accuracy, safety, and speed.

- Comprehensive sections: In some cases, candidates may be required to demonstrate knowledge across various areas, such as maintenance protocols, safety standards, and operational procedures.

Interpreting Your Results

Once the test is completed, candidates will receive their results, which typically include both a score and an assessment of their performance in different areas. Understanding how to interpret these results is essential for determining next steps and identifying areas for improvement. Results may include:

- Total score: Your overall performance based on the entire test. A passing score is usually set as a minimum threshold that you must meet or exceed.

- Section performance: In some tests, you may receive feedback on specific areas, such as knowledge of safety standards or practical gear maintenance. This helps you identify strong and weak points.

- Pass/fail status: Some tests provide a simple pass/fail result, while others may give a detailed breakdown of how well you performed.

In addition to your score, feedback on areas that need improvement can guide your future study efforts. Whether you pass or need to retake certain sections, understanding your results is an important step toward achieving certification.

Why Follow Safety and Maintenance Guidelines

Adhering to safety and maintenance protocols is essential for ensuring the longevity and reliability of protective gear. These guidelines are designed not only to protect individuals in hazardous situations but also to ensure that equipment functions optimally when needed most. By following established standards, organizations and individuals help maintain safety, reduce risks, and meet compliance requirements.

Ensuring Maximum Protection

One of the primary reasons to follow maintenance and safety protocols is to guarantee that protective equipment continues to offer the highest level of safety. Regular inspections and care help to identify potential weaknesses, damage, or wear and tear that could compromise the gear’s effectiveness. Following established guidelines ensures that:

- Protective gear remains durable: Proper cleaning, repairs, and inspections extend the life of gear.

- Equipment performs as expected: Consistent maintenance ensures functionality during emergency situations.

- Wearers are adequately protected: Well-maintained gear provides optimal protection against environmental hazards and potential injuries.

Compliance and Legal Considerations

Many industries have strict regulations regarding the maintenance of protective gear. Following established safety standards helps ensure that individuals and organizations remain in compliance with these legal requirements. Adhering to these guidelines also reduces the risk of legal liability in the event of accidents or incidents, as it demonstrates a commitment to maintaining high safety standards.

- Meet regulatory standards: Compliance with safety protocols is often mandated by law or industry regulations.

- Avoid legal risks: Proper maintenance reduces the risk of non-compliance penalties and liability claims.

- Protect the organization’s reputation: Ensuring the safety of employees and equipment enhances trust and reliability in the workplace.

By consistently following these guidelines, you not only protect yourself and others but also help create a safer, more reliable environment in which everyone can perform their best.

PPE Features and Requirements

Personal protective equipment (PPE) is essential for safeguarding individuals in high-risk environments, such as firefighting, industrial work, or hazardous materials handling. PPE must be designed with specific features that ensure both safety and comfort while meeting stringent industry standards. These standards not only ensure the durability and functionality of the equipment but also enhance the wearer’s protection against a wide range of potential dangers.

Key Features of High-Quality PPE

When selecting protective gear, certain features are non-negotiable. These characteristics ensure the gear provides optimal protection while maintaining comfort and mobility. Some of the most important features include:

- Durability: Protective clothing and gear must withstand extreme conditions, such as high temperatures, sharp objects, and harsh weather, without compromising the safety of the user.

- Breathability and Comfort: PPE must allow for adequate airflow to prevent overheating and discomfort during prolonged use, while still providing necessary protection.

- Resistance to Hazardous Materials: Gear must be resistant to chemicals, fire, and other environmental hazards, depending on the specific risks of the job.

- Proper Fit: Well-fitting protective equipment ensures maximum coverage and prevents gaps where hazards could potentially cause injury.

Requirements for Compliance

To ensure the highest levels of protection, PPE must meet certain requirements set by safety organizations and regulatory bodies. Compliance with these standards is crucial to ensure the equipment is effective in protecting against identified risks. Key requirements include:

- Certification: PPE must be certified by relevant safety standards to ensure it meets or exceeds minimum performance criteria.

- Regular Inspections: Continuous maintenance and regular inspections are required to ensure that PPE remains in good condition and continues to meet safety standards.

- Training: Proper training on the use and care of PPE is essential for ensuring that users understand how to properly wear, maintain, and inspect their equipment.

- Quality Materials: The use of high-quality materials is essential for PPE to be effective in protecting against various hazards while maintaining comfort and ease of movement.

Meeting these features and requirements ensures that protective gear not only provides effective protection but also supports the comfort and efficiency of the wearer in hazardous environments.

Firefighter Safety and PPE Training

Firefighting is one of the most dangerous professions, requiring individuals to work in life-threatening conditions. The key to ensuring their safety lies in proper training and the effective use of personal protective equipment (PPE). Comprehensive training programs focus on both the technical skills needed for fire suppression and emergency response, as well as the critical importance of PPE in maintaining safety throughout the process.

Essential Aspects of Firefighter Safety

To effectively mitigate the risks associated with firefighting, it is essential to understand both the dangers involved and the role of protective gear in minimizing these risks. Firefighter safety protocols aim to:

- Protect from Heat and Fire: PPE is designed to shield firefighters from extreme temperatures, flame exposure, and the risk of burns.

- Minimize Exposure to Hazardous Materials: Firefighters may encounter hazardous chemicals, smoke, or toxins. PPE is designed to protect against these dangers.

- Prevent Physical Injuries: Firefighting involves navigating through unstable and dangerous environments. Proper gear helps prevent injuries caused by falls, cuts, or abrasions.

- Improve Visibility and Communication: Properly fitted PPE includes reflective materials and communication tools to ensure visibility and effective team coordination during emergencies.

Importance of PPE Training for Firefighters

Training is essential to ensure that firefighters understand how to properly use, maintain, and inspect their protective gear. This includes:

- Correct Gear Usage: Firefighters must be trained on how to properly wear and adjust their PPE for maximum protection and comfort.

- Gear Maintenance: Regular inspections, cleaning, and repairs are critical to keeping the PPE in top working condition and ensuring it continues to meet safety standards.

- Recognizing Gear Deficiencies: Training ensures firefighters can identify when their gear is damaged or no longer provides adequate protection, which is crucial for preventing injuries.

- Simulated Emergency Drills: Training programs often involve simulated fire and rescue scenarios to help firefighters practice using their PPE in real-world conditions, ensuring they are prepared for any situation.

Ongoing education and hands-on practice with PPE are essential for maintaining firefighter safety. Ensuring that all personnel are well-equipped and well-trained contributes to both their well-being and their ability to perform their duties effectively in hazardous environments.

Certification Benefits for Firefighters

Achieving certification in safety and equipment standards provides numerous advantages for firefighters. These certifications not only validate a firefighter’s skills and knowledge but also ensure they adhere to the highest safety protocols. The certification process offers a structured approach to training and ensures that fire services maintain operational excellence. For firefighters, the benefits of being certified extend beyond individual competence to broader team safety and career development.

Improved Safety Standards

Certification ensures that firefighters are thoroughly trained in the latest safety procedures and equipment maintenance practices. This knowledge directly translates to better protection in hazardous environments. Key benefits include:

- Minimized Risk of Injury: Firefighters are taught to recognize hazards and respond appropriately, ensuring their safety when entering dangerous situations.

- Compliance with Industry Standards: Certifications confirm that safety protocols are followed, ensuring that protective gear and techniques are up-to-date and meet all safety requirements.

- Enhanced Protection: Well-maintained equipment that meets certification standards is crucial for safeguarding against injuries from exposure to heat, chemicals, and physical dangers.

Professional Development and Career Advancement

For firefighters, certifications are a valuable asset in terms of career growth. The benefits extend to enhanced skills and professional recognition:

- Job Security: Certified firefighters are often considered more reliable and knowledgeable, making them more competitive in the job market.

- Increased Opportunities: Many fire departments prioritize hiring or promoting firefighters who hold recognized certifications, offering them better career prospects.

- Ongoing Learning: Certification programs often require continuous education, keeping firefighters up-to-date on the latest techniques and safety measures.

In addition to these advantages, certification fosters a culture of safety and preparedness, benefiting not only individual firefighters but also the entire firefighting community.