In any environment where people prepare and serve meals, understanding the proper procedures and regulations is crucial. This section covers the key aspects of ensuring that every step in the preparation and distribution of meals meets the highest standards of health and hygiene. Knowledge of these practices is essential for everyone working in the kitchen or serving food to the public.

Whether you’re in a restaurant, catering service, or any other setting, the ability to identify risks and prevent contamination plays a pivotal role in maintaining a safe and clean environment. Mastery of these principles not only helps avoid potential health hazards but also ensures compliance with local regulations, providing peace of mind for both employees and customers.

Preparation for a career in food-related services requires familiarity with various guidelines that are designed to promote well-being. From the correct way to handle ingredients to the procedures for cleaning and sanitizing surfaces, each element is vital. By fully understanding these concepts, you can ensure optimal conditions for both the staff and those they serve.

Food Safety for Handlers Final Exam Answers

Successfully completing a certification in food-related practices requires a deep understanding of critical concepts that ensure public health. This section outlines the most important topics and guidelines that will help anyone working with meals achieve the required proficiency. Knowing these key principles can significantly improve performance and boost confidence when faced with a comprehensive assessment.

Key Concepts to Master

There are several core areas that every professional should be familiar with in order to pass the certification process with ease. The following areas are essential:

- Proper handling and storage of ingredients

- Hygiene standards for personal cleanliness and sanitation

- Temperature controls for both hot and cold items

- Prevention of contamination through cross-contact

- Understanding potential risks and how to minimize them

Preparation Tips

To ensure success, consider the following tips while preparing for the assessment:

- Study the guidelines thoroughly and focus on practical applications.

- Review common health violations and how to avoid them.

- Ensure familiarity with the specific rules and regulations in your area.

- Practice the correct techniques and procedures consistently.

- Take time to understand both the theory and the real-world scenarios you may encounter.

Mastering these concepts will not only help you pass the assessment but will also support you in creating a safe environment for both workers and customers.

Key Concepts in Food Safety Exams

To successfully complete a certification in the food service industry, it is crucial to grasp the fundamental principles that ensure health and well-being. These concepts are not only vital for passing assessments but also for maintaining the highest standards in any establishment that handles meals. Mastery of these areas guarantees a safer environment for both staff and customers.

Critical Areas to Focus On

Several core areas are tested to ensure that individuals understand the risks and best practices involved in meal preparation and service. The following are central topics:

- Correct methods of storing ingredients to prevent contamination

- Hygiene practices for staff to reduce the risk of illness

- Temperature management to avoid spoilage and bacterial growth

- Techniques to avoid cross-contamination between raw and cooked items

- Proper sanitization of kitchen tools and surfaces

Real-World Applications

Understanding the theory behind these principles is just the beginning. In the real world, they must be applied consistently and correctly. Being familiar with practical scenarios and knowing how to handle various situations is just as important as theoretical knowledge. Ensuring that these practices are second nature will help you create a safe environment and pass any relevant tests.

Top Mistakes to Avoid During the Exam

When preparing for an assessment related to meal handling and public health, it’s crucial to avoid common pitfalls that can lead to mistakes or misunderstandings. Being aware of these issues can not only help in achieving success but also ensures that the correct principles are applied in real-life scenarios. Knowing where others often struggle can give you an edge in the process.

Common Errors to Watch Out For

These mistakes are frequently encountered and can negatively impact performance:

- Ignoring key hygiene practices and their importance

- Overlooking critical temperature requirements for ingredients

- Failing to read questions thoroughly before answering

- Rushing through the material without fully understanding key concepts

- Underestimating the role of cleaning and sanitization in preventing illness

Preparation Tips to Prevent Mistakes

To avoid these common errors, consider the following strategies:

- Review the material multiple times to reinforce your understanding.

- Focus on practical applications, as these are often the most relevant.

- Take your time to read through each question carefully during the test.

- Double-check your answers to ensure accuracy before submitting.

- Practice scenarios that simulate real-world challenges and decision-making.

Common Foodborne Illnesses to Know

Understanding the most prevalent illnesses caused by improper handling and preparation of meals is crucial for anyone involved in the service industry. Knowledge of these diseases, how they spread, and how to prevent them is essential in ensuring the well-being of consumers and maintaining a hygienic environment. Familiarizing yourself with these pathogens can help reduce risks and improve practices in any meal-related setting.

Most Common Pathogens to Watch

Several harmful microorganisms are frequently associated with contamination. The following are among the most important to understand:

- Salmonella: Often found in undercooked poultry and eggs, it can lead to severe gastrointestinal illness.

- Norovirus: A highly contagious virus that spreads easily through contaminated water or surfaces.

- Escherichia coli (E. coli): Found in raw meat, especially beef, it can cause serious stomach distress.

- Campylobacter: Commonly found in poultry, it can lead to fever, diarrhea, and stomach cramps.

- Listeria: This bacteria can grow at refrigerator temperatures, often contaminating dairy products and deli meats.

Preventing Illnesses and Reducing Risk

Preventing the spread of these pathogens requires careful attention to hygiene and food preparation standards. Some key steps include:

- Thoroughly cooking meats and eggs to the correct internal temperature.

- Practicing good handwashing habits, especially after handling raw products.

- Ensuring proper storage conditions, including refrigeration and separation of raw and ready-to-eat items.

- Regularly sanitizing kitchen surfaces and utensils to avoid cross-contamination.

By understanding and implementing these preventative measures, anyone involved in meal preparation can significantly reduce the risk of illness outbreaks.

Handling and Storing Food Safely

Proper management of ingredients and prepared items is crucial in preventing contamination and spoilage. Correct handling techniques, coupled with the right storage practices, help maintain the quality of products while ensuring that harmful bacteria or pathogens don’t spread. Knowing how to store and handle items at various stages of the process is essential in maintaining hygiene and preventing illness.

Essential Handling Practices

Proper handling reduces the risk of contamination and ensures that ingredients are prepared safely. Key practices include:

- Always wash hands thoroughly before and after handling raw items.

- Use separate utensils and surfaces for raw and cooked items to avoid cross-contamination.

- Ensure that items are kept at the correct temperature during preparation to minimize bacterial growth.

- Check expiration dates regularly and avoid using expired products.

Best Storage Guidelines

Storing items properly is just as important as handling them correctly. Proper storage helps preserve freshness and prevents contamination. The following tips will help:

- Keep perishable items refrigerated or frozen at the correct temperature.

- Store raw items separately from ready-to-eat products to avoid cross-contact.

- Label and date items to ensure they are used within a safe time frame.

- Regularly clean and maintain storage units to prevent bacterial build-up.

By following these best practices, individuals can help ensure that ingredients and meals are handled and stored in the most hygienic and safe way possible, reducing the risk of health issues for consumers.

Critical Temperature Guidelines for Food

Maintaining the proper temperature during the handling, storage, and cooking of ingredients is essential for reducing the risk of harmful microbial growth. Every type of ingredient has an optimal temperature range to ensure its safety and quality. Knowing and following these guidelines is key to preventing contamination and ensuring that prepared dishes are safe for consumption.

| Temperature Range | Process/Action | Recommended Items |

|---|---|---|

| Below 41°F (5°C) | Refrigeration | Raw proteins, dairy, prepared salads |

| 41°F to 135°F (5°C to 57°C) | Danger Zone | Perishable items not to be stored or held in this range |

| Above 135°F (57°C) | Hot Holding | Cooked meats, stews, soups |

| 165°F (74°C) | Cooking | Poultry, stuffed foods, reheated leftovers |

| 145°F (63°C) | Cooking | Beef, lamb, pork steaks, roasts |

| 140°F (60°C) | Reheating | Cooked meals, soups, sauces |

Monitoring temperatures at each stage of the process ensures that ingredients and prepared dishes stay within safe limits, reducing the chances of contamination and preserving the quality of the meal. Always use thermometers to verify temperatures and avoid keeping items within the danger zone for too long.

Personal Hygiene Requirements for Food Handlers

Maintaining proper cleanliness and personal hygiene is essential in any environment where ingredients are prepared or served. Ensuring that individuals involved in the process adhere to strict hygiene standards helps prevent the transfer of harmful bacteria and other contaminants. Below are the key hygiene practices that must be followed to minimize risks and maintain a sanitary environment.

Basic Hygiene Practices

The following guidelines should be followed by all individuals working in preparation or serving areas:

| Action | Requirement |

|---|---|

| Hand Washing | Wash hands thoroughly with soap and water before and after handling ingredients, after using the restroom, and after touching contaminated surfaces. |

| Personal Cleanliness | Ensure clean clothing, hair restraints (such as hairnets or hats), and proper footwear are worn at all times. |

| Health Status | Individuals showing symptoms of illness such as vomiting, diarrhea, or fever should avoid working with ingredients until fully recovered. |

Additional Hygiene Guidelines

Beyond basic cleanliness, these additional practices further enhance hygiene standards:

| Action | Requirement |

|---|---|

| Gloves and Utensils | When handling raw ingredients, use gloves and change them frequently to prevent contamination. Always use clean utensils for food preparation. |

| Personal Habits | Avoid touching the face, hair, or clothing while working with ingredients. Do not smoke or chew gum in food preparation areas. |

| Illness Reporting | Staff should report any symptoms of illness immediately to management, and steps should be taken to prevent the spread of any potential contamination. |

By following these hygiene practices, individuals can significantly reduce the risk of contamination and ensure that all items handled are kept in a sanitary condition. Regular training and adherence to hygiene protocols are crucial in maintaining a safe and clean environment.

How to Properly Sanitize Kitchen Tools

Proper sanitation of kitchen tools is essential to prevent contamination and ensure the cleanliness of every item used in the preparation process. Without effective cleaning, harmful bacteria and residues can linger on surfaces, leading to potential risks. Here are the steps and guidelines for properly sanitizing kitchen tools to maintain a safe and hygienic environment.

Steps to Sanitize Kitchen Tools

Follow these basic steps to ensure all kitchen tools are properly sanitized:

| Step | Action |

|---|---|

| Step 1 | Rinse tools with warm water to remove any food debris or visible contaminants. |

| Step 2 | Apply a cleaning solution, such as dish soap, to the tool and scrub thoroughly using a brush or sponge. |

| Step 3 | Rinse the tool again with hot water to remove soap residues. |

| Step 4 | Disinfect the tool by soaking it in a sanitizing solution (such as diluted bleach or a commercial sanitizer) for the recommended time. |

| Step 5 | Allow the tool to air dry completely, or dry it with a clean cloth to prevent recontamination. |

Commonly Used Sanitizing Solutions

Choosing the right sanitizing solution is key to effectively eliminating harmful microorganisms. Here are some commonly used disinfectants:

| Solution | Concentration | Use |

|---|---|---|

| Bleach Solution | 1 tablespoon of bleach per gallon of water | Commonly used for sanitizing countertops, cutting boards, and utensils. |

| Commercial Sanitizers | Follow manufacturer’s instructions | Effective for both utensils and surfaces, often used in commercial kitchens. |

| Vinegar Solution | 1 part vinegar to 1 part water | A natural alternative for sanitizing certain tools and surfaces. |

By consistently following these steps and using the appropriate sanitizers, kitchen tools will remain free of harmful germs and residues, ensuring a clean and hygienic preparation area. Regular cleaning and sanitizing help minimize health risks and maintain a professional standard in food preparation areas.

Food Safety Laws and Regulations Overview

To ensure the protection of public health, various laws and regulations are in place that govern the handling, preparation, and distribution of consumable goods. These rules are designed to prevent contamination, spread of illnesses, and ensure that items sold or served are of high quality and safe to consume. Below is an overview of key regulations and guidelines that apply across different industries.

Key Regulatory Agencies

Several organizations are responsible for enforcing regulations that oversee the safety of consumable goods. These agencies set guidelines and standards for cleanliness, temperature control, and handling practices:

- FDA (Food and Drug Administration): Responsible for ensuring that food and beverages meet safety standards, including proper labeling and safety of ingredients.

- USDA (United States Department of Agriculture): Oversees the safety of meat, poultry, and processed egg products, ensuring they are safe for consumption.

- EPA (Environmental Protection Agency): Regulates the use of pesticides and ensures that chemicals used in food production do not pose a threat to consumers.

Important Regulations and Guidelines

These are some of the most crucial laws that shape industry practices:

- HACCP (Hazard Analysis and Critical Control Points): A systematic preventive approach to food safety that addresses physical, chemical, and biological hazards.

- FSMA (Food Safety Modernization Act): A set of regulations aimed at improving the safety of food by shifting the focus from responding to contamination to preventing it.

- Good Manufacturing Practices (GMP): Guidelines that ensure proper facility conditions, hygiene practices, and quality control during production.

By adhering to these standards, food producers and distributors can minimize health risks and ensure that their products are safe and of high quality. Continuous compliance with these regulations is essential to maintaining public trust and protecting consumer health.

Essential Tips for Success

Preparation is key when it comes to achieving success in assessments. Knowing the material is important, but so is understanding how to approach the test itself. Whether you are tackling a written or practical evaluation, effective strategies can make a significant difference in your performance. Below are essential tips that can help you excel during the assessment process.

Study Techniques to Enhance Retention

Successful test-takers often use focused study techniques to ensure they retain key information. Here are some methods to help boost your learning:

- Active Recall: Test yourself on the material regularly. By actively trying to recall information, you strengthen your memory and understanding.

- Spaced Repetition: Review topics periodically over increasing intervals to ensure long-term retention.

- Practice Questions: Solve practice tests or quizzes to familiarize yourself with the format and types of questions you may encounter.

Test-Taking Strategies for Efficiency

Once you’re in the testing environment, it’s important to stay calm and focused. Here are some strategies to help you manage your time and approach each question effectively:

- Time Management: Allocate time for each section and stick to it. Don’t spend too much time on any one question.

- Read Carefully: Read each question thoroughly before answering. Pay attention to details and instructions.

- Answer What You Know First: Begin with the questions you feel confident about. This will help build momentum and reduce stress.

By employing these strategies, you’ll be better equipped to navigate the assessment process with confidence and maximize your chances of success.

Understanding Cross-Contamination Prevention

Preventing the transfer of harmful microorganisms from one surface, substance, or item to another is crucial in maintaining the integrity and health standards of any preparation process. This transfer, known as cross-contamination, can occur in numerous ways, often unknowingly, and poses significant risks to public health. Effective management and proper practices are key to minimizing these risks and ensuring a safe environment for everyone involved.

Key Areas of Risk for Cross-Contamination

Several common practices or points within a workspace are high-risk areas for the transfer of bacteria, allergens, or other contaminants. Recognizing these potential hazards can help prevent issues:

- Surfaces and Utensils: Shared cutting boards, knives, and other tools can harbor bacteria, especially if not cleaned thoroughly between uses.

- Raw and Cooked Products: Storing or preparing raw items near ready-to-eat products is a common mistake that can lead to the transfer of harmful pathogens.

- Hands and Clothing: Improper hand hygiene or contaminated clothing can introduce bacteria to items that will be consumed.

Effective Cross-Contamination Prevention Practices

By adopting a few simple practices, the likelihood of cross-contamination can be greatly reduced. Here are some key steps:

- Separate Tasks: Use different tools, surfaces, and containers for raw and cooked items. This minimizes the risk of cross-contact.

- Thorough Cleaning: Regularly sanitize all surfaces and utensils, particularly between handling different items, to eliminate bacteria.

- Proper Storage: Store raw items, especially meats, in separate areas or sealed containers to prevent leakage or contact with other products.

By understanding and implementing these guidelines, workers can significantly reduce the risk of contamination and ensure a higher standard of hygiene and health protection for all involved.

Food Handling Practices in High-Risk Areas

In certain environments, the risk of contamination is significantly higher due to the nature of the tasks and the items being worked with. These areas require extra vigilance and adherence to stringent protocols to ensure that harmful microorganisms do not spread and cause harm. Whether it’s because of high volumes of activity, the types of materials handled, or the conditions in which items are prepared or stored, specialized procedures are essential in these high-risk zones.

High-risk areas include environments where raw items are handled, such as in processing zones, kitchens, or storage spaces. These areas are prone to contamination due to the constant movement of materials, often in contact with various surfaces or equipment that may not be properly sanitized. Workers in these areas must take special care to minimize contact between different substances and ensure that hygiene protocols are followed at every stage.

To ensure optimal conditions and reduce risk, certain practices are fundamental in these environments:

- Regular Cleaning and Disinfection: Surfaces, equipment, and utensils must be cleaned frequently, particularly between different tasks, to prevent the spread of harmful bacteria.

- Personal Hygiene: Workers should practice proper hand washing techniques, wear protective gear, and avoid touching their faces or other non-hygienic surfaces to reduce contamination risks.

- Temperature Control: Ensuring that products are kept within the correct temperature ranges is vital for preventing the growth of harmful microorganisms.

- Cross-Contamination Prevention: Always use separate equipment for raw and cooked materials, and store products correctly to avoid contact between potentially harmful substances.

Implementing these practices consistently in high-risk areas can significantly reduce the likelihood of contamination, maintaining a secure and hygienic environment throughout the entire process.

Understanding HACCP in Food Safety

The concept of preventing risks and ensuring quality at every stage of the production process is essential in maintaining high standards. A systematic approach is required to identify and address potential hazards before they become issues. By focusing on critical points within the process, businesses can proactively prevent problems rather than react to them after they occur. This approach helps ensure that products meet both regulatory requirements and consumer expectations.

HACCP, or Hazard Analysis and Critical Control Points, is a widely recognized system designed to assess and manage risks in various stages of production. It focuses on identifying key points where hazards could occur and implementing measures to control or eliminate these risks. From raw materials to the final product, this system plays a crucial role in maintaining quality and minimizing health hazards.

Key Principles of HACCP

The HACCP system is built upon seven key principles, each of which plays a vital role in identifying and controlling risks:

- Conduct a Hazard Analysis: Identify potential hazards that could affect the product at any stage of production.

- Determine Critical Control Points (CCPs): Identify the steps where risks can be controlled or eliminated.

- Establish Critical Limits: Set measurable standards to ensure each CCP is under control.

- Monitor CCPs: Regularly monitor the identified critical points to ensure they remain within established limits.

- Establish Corrective Actions: Define steps to be taken when a deviation occurs to bring the process back into control.

- Verification: Ensure the system is working as intended through audits and tests.

- Record Keeping: Maintain accurate documentation to track actions, decisions, and corrective measures taken throughout the process.

Benefits of HACCP

Implementing a HACCP-based approach can significantly reduce the risk of contamination, improve product quality, and increase consumer trust. By focusing on prevention, businesses can not only comply with regulatory requirements but also enhance operational efficiency and maintain a strong reputation in the market.

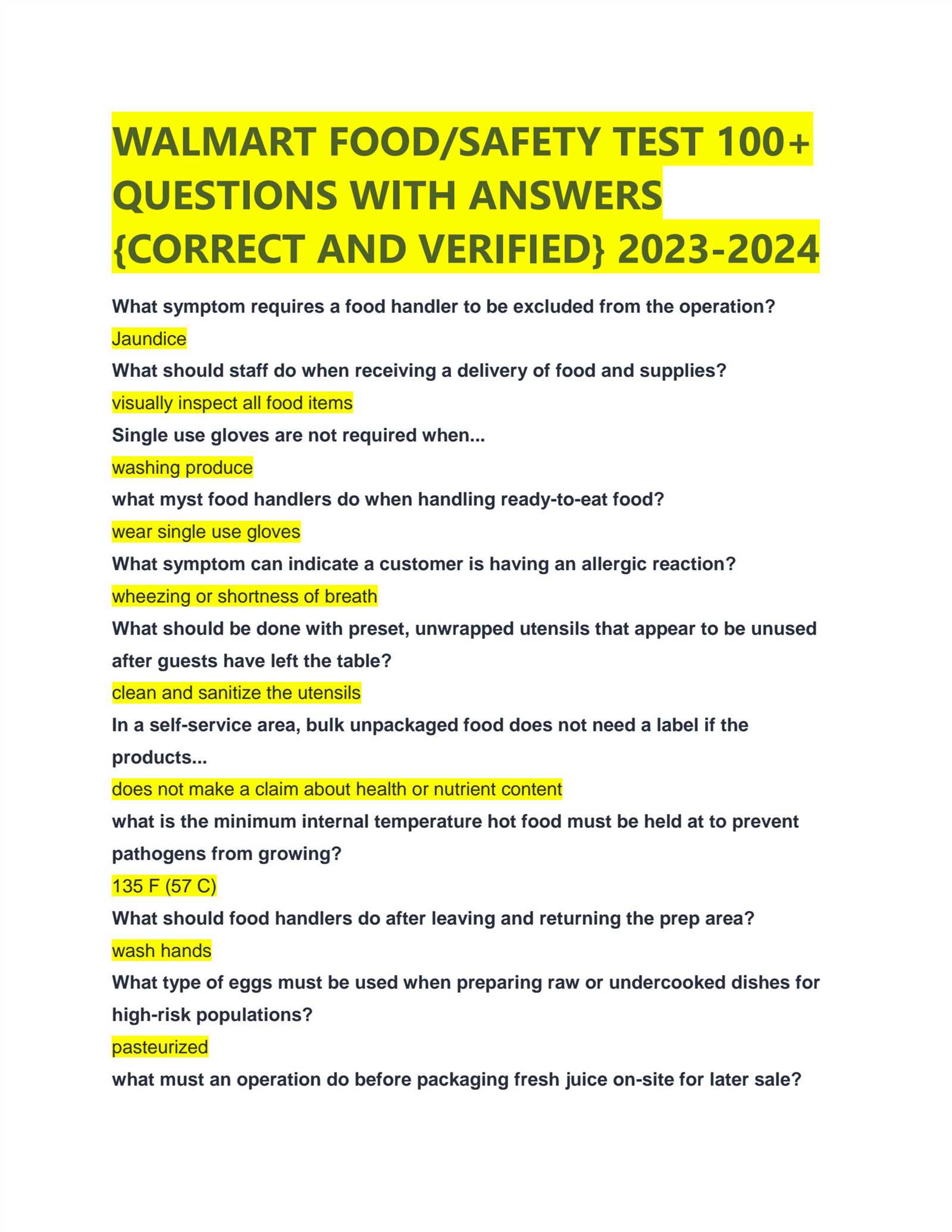

Commonly Asked Questions on the Exam

When preparing for any certification assessment, it’s important to anticipate the types of questions that will be asked. Understanding the most frequently covered topics can help focus your study efforts. By familiarizing yourself with common scenarios and best practices, you can be better equipped to answer questions efficiently and accurately.

This section outlines some of the most commonly asked questions, which often focus on the key concepts and guidelines that ensure proper procedures are followed in various environments. These questions test knowledge of critical principles, as well as the ability to apply them in real-life situations.

Frequently Covered Topics

- Risk Assessment and Control: Questions often ask how to identify potential hazards and determine the best measures to control or eliminate them.

- Correct Procedures: Expect questions on the correct practices to follow when dealing with sensitive materials, such as proper storage, handling, and temperature control.

- Legal Requirements: Some questions focus on regulations and laws that govern specific practices, testing your understanding of compliance requirements.

- Health Risks: Questions may ask about common diseases or illnesses, how they spread, and how to prevent contamination.

- Monitoring and Corrective Actions: Be prepared for questions on how to monitor processes and what actions to take if issues arise during production or handling.

Sample Question Breakdown

- What is the most effective way to control temperature for perishable goods?

- Which methods are recommended to avoid cross-contamination?

- What are the proper steps to take when a product is found to be at a critical risk point?

- What are the legal time frames for safely storing certain products?

- Explain the difference between cleaning and sanitizing, and when each should be done.

By practicing these types of questions, you can gain a better understanding of what will be expected of you during the assessment and increase your chances of success.

Role of Training Programs

Training initiatives play a crucial role in ensuring that individuals working in environments with strict health protocols understand the critical guidelines necessary for maintaining high standards. These programs provide the foundational knowledge required to prevent risks, adhere to best practices, and mitigate potential hazards that could arise in various settings. They offer employees the tools to perform their duties safely and effectively while reducing the likelihood of contamination or mishandling.

Proper education and awareness programs are essential for minimizing errors and ensuring that all individuals, from entry-level workers to managers, are well-informed about proper techniques and legal requirements. These training courses typically focus on practical, actionable knowledge that can be immediately applied in daily operations, fostering a culture of responsibility and compliance.

Key Benefits of Training

- Improved Knowledge: Participants gain a deeper understanding of potential risks, correct handling procedures, and necessary precautions to avoid contamination.

- Compliance with Regulations: Proper training ensures that all individuals are aware of and adhere to local and international regulations governing health standards.

- Reduced Incidents: Regular training significantly reduces the likelihood of mistakes and accidents, preventing costly errors that could harm individuals or organizations.

- Enhanced Confidence: Well-trained employees feel more confident in their roles, leading to better performance and more proactive problem-solving.

Training Program Components

- Introduction to Key Guidelines: Overview of essential protocols and legal requirements.

- Practical Demonstrations: Hands-on exercises and scenarios to reinforce learning and prepare employees for real-life situations.

- Continuous Education: Ongoing updates to keep employees informed of new regulations and best practices in the industry.

- Evaluation and Certification: Testing and certification to ensure participants have acquired the necessary knowledge and skills.

Through comprehensive and ongoing training, organizations can ensure their workforce is equipped to maintain high standards and avoid common risks, ultimately contributing to a safer and more efficient work environment.

Preparing for Your Certification Test

Proper preparation is essential when it comes to ensuring success in any certification process. Whether you’re looking to validate your skills or expand your knowledge, understanding the key areas of focus and how to approach your studies is crucial. This section will provide guidance on how to effectively prepare for your upcoming test, helping you to boost your confidence and achieve your desired results.

First, it’s important to review the key concepts that will be assessed. These may include topics related to health regulations, hygiene protocols, and methods to reduce risks. Knowing what areas to prioritize and dedicating time to studying each one can significantly improve your chances of success. Make sure to focus on both theoretical knowledge and practical applications, as exams often test both types of understanding.

Study Tips for Success

- Create a Study Schedule: Plan your study sessions well in advance to ensure adequate coverage of all the necessary material.

- Use Practice Materials: Take advantage of practice questions or mock tests to familiarize yourself with the test format and identify areas that need further attention.

- Focus on Key Regulations: Pay close attention to any legal and regulatory guidelines that are specific to the industry, as these are often a significant portion of the test.

- Review Case Studies: Study real-world scenarios and examples to understand how to apply your knowledge to practical situations.

Staying Calm and Confident

- Get Plenty of Rest: A well-rested mind performs better, so make sure to get enough sleep before the test.

- Stay Positive: A confident attitude can make a big difference. Approach the test with a calm and focused mindset.

- Read Questions Carefully: Take your time to understand each question fully before answering, ensuring you choose the most accurate response.

By following these tips and staying organized, you can maximize your chances of performing well and earning your certification. Remember, thorough preparation is the key to success.