Ensuring a safe environment for customers and staff is a fundamental aspect of working in any food-related industry. Whether you’re preparing meals or serving, knowledge of proper safety guidelines is essential for maintaining hygiene and preventing health risks. The process of learning and demonstrating this knowledge is crucial for anyone looking to advance in the industry.

Throughout this guide, we will explore key principles that professionals must understand to meet required standards. These include preventing contamination, maintaining cleanliness, and understanding temperature control. By familiarizing yourself with these topics, you’ll gain confidence in your ability to apply these practices effectively in the workplace.

In-depth preparation is vital to mastering these concepts, as it directly impacts your ability to perform in real-world situations. Whether you’re new to the field or looking to refresh your skills, this guide will provide you with the tools needed to excel.

Essential Knowledge for Safety Certification

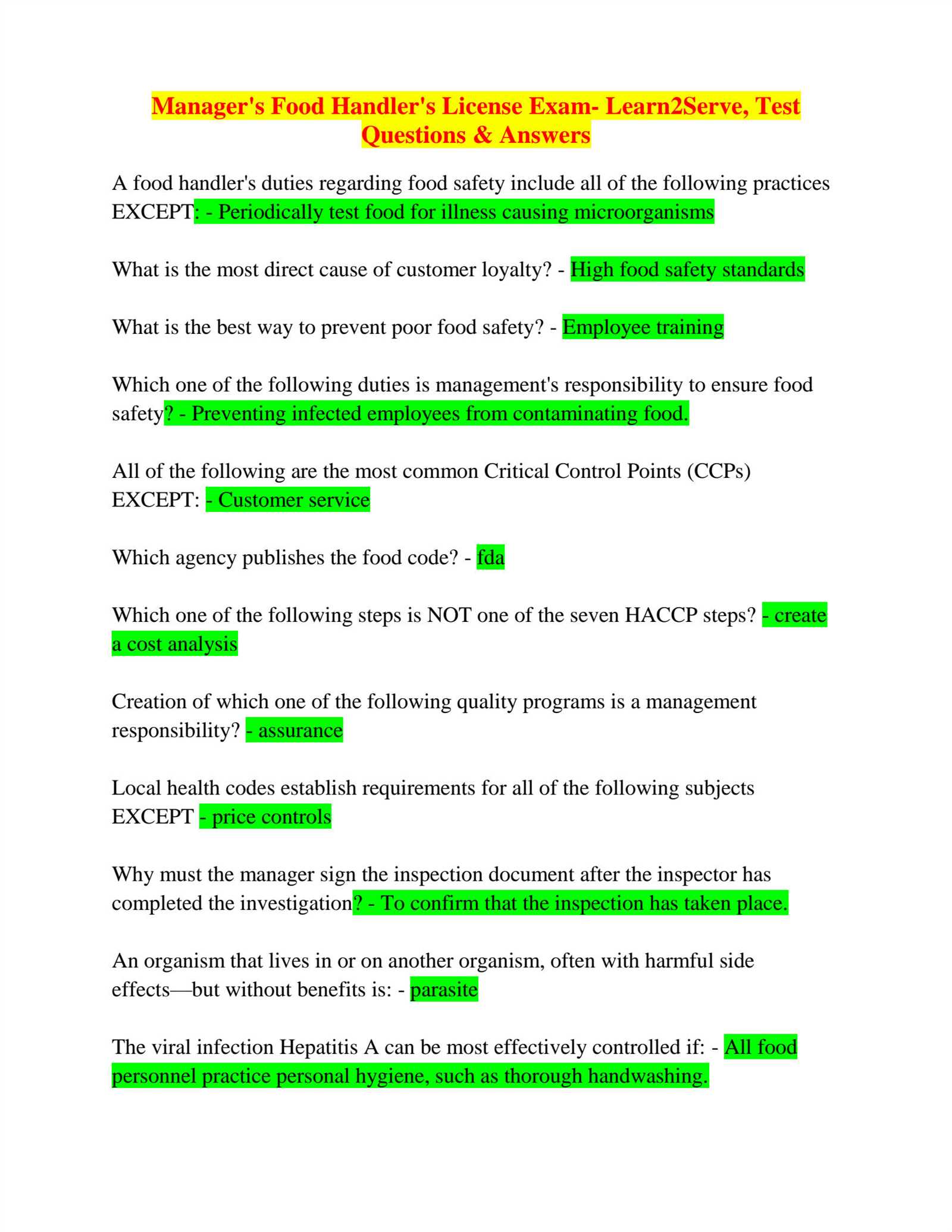

To pass the certification process for working in a food-related environment, it’s essential to demonstrate a deep understanding of safety procedures. The test is designed to assess your ability to apply correct practices to prevent contamination, maintain cleanliness, and ensure the health of everyone in the workplace. Successful completion of this process shows you are equipped to manage the risks associated with food preparation and service.

Key Topics to Focus On

When preparing for the certification process, there are several important areas you should prioritize. Here are the most critical topics you need to understand:

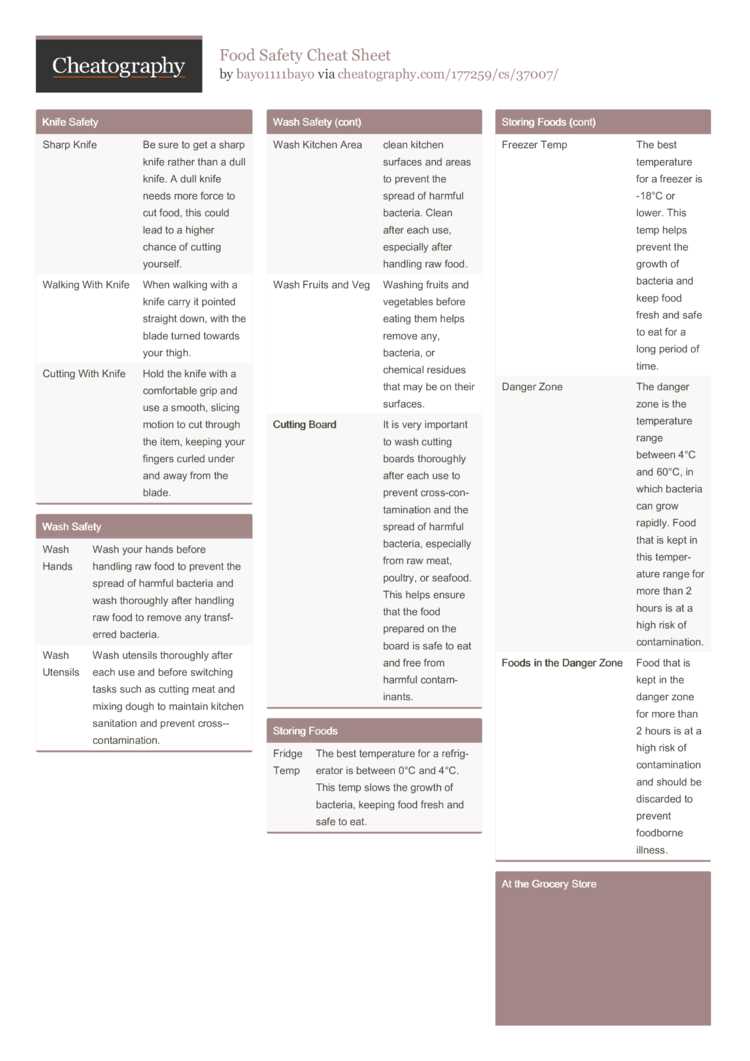

- Sanitation Practices: Proper cleaning and disinfecting methods are crucial for preventing cross-contamination and maintaining hygiene.

- Temperature Control: Knowledge of correct temperature levels for storage and cooking is vital to prevent harmful bacteria growth.

- Personal Hygiene: Consistently practicing good personal hygiene, such as handwashing and avoiding illness, helps minimize contamination risks.

- Food Handling Techniques: Safe methods of handling, storing, and preparing ingredients are essential for food safety.

- Legal Requirements: Understanding local regulations and guidelines ensures you comply with industry standards and laws.

How to Approach the Test

To succeed, it’s important to study in a focused manner. Here are some tips to help you prepare:

- Review Key Concepts: Go through the material thoroughly and make sure you understand all essential safety protocols.

- Practice with Mock Tests: Use practice exams to familiarize yourself with the question format and identify areas where you need improvement.

- Stay Updated: Safety standards can change, so ensure you’re working with the most current information available.

- Seek Additional Resources: If you’re unsure about any topics, look for online resources or professional courses that provide more in-depth knowledge.

By focusing on these areas, you’ll be better prepared to pass the certification and apply your skills in any food service environment.

Understanding Safety Regulations

In any industry where handling and preparation of consumables are involved, it’s crucial to adhere to strict guidelines aimed at ensuring health and hygiene. Regulations are in place to minimize risks and protect both consumers and workers. Understanding these standards is essential for anyone involved in the process, as it helps to maintain a safe environment and prevent contamination.

These guidelines cover a wide range of practices, from personal hygiene to proper storage and handling techniques. Compliance with these standards ensures that the workplace remains safe and efficient, reducing the likelihood of illness or injury due to improper procedures.

Key Safety Regulations to Know

The following table outlines some of the fundamental safety regulations that should be followed in any environment where consumables are handled:

| Regulation | Description | Importance |

|---|---|---|

| Temperature Control | Ensuring proper temperature for storage and cooking to prevent bacterial growth. | Reduces risk of foodborne illnesses. |

| Personal Hygiene | Regular handwashing, avoiding illness, and wearing appropriate attire. | Prevents contamination through direct contact with materials. |

| Cross-Contamination Prevention | Keeping raw and cooked items separate to avoid contamination. | Minimizes the risk of harmful pathogens spreading. |

| Proper Cleaning and Sanitizing | Regular cleaning of equipment and surfaces to maintain a hygienic environment. | Ensures safe and sanitary conditions throughout the workplace. |

| Storage Guidelines | Correctly storing ingredients at the right temperatures and conditions. | Helps prevent spoilage and bacterial contamination. |

Familiarity with these regulations is not only necessary for passing certification but also for performing day-to-day tasks safely. By following these rules, workers can contribute to a safer and healthier environment for everyone involved.

Common Questions on Food Handling

In any environment where consumables are prepared or served, questions about best practices and safety standards often arise. These questions are essential for ensuring that proper procedures are followed, minimizing the risk of contamination and ensuring the well-being of consumers. Understanding the most common concerns can help workers stay informed and make better decisions in their daily tasks.

Here are some frequently asked questions that address the core aspects of handling items safely and effectively:

- How often should hands be washed? It’s crucial to wash hands frequently, especially after handling raw ingredients, using the restroom, or touching potentially contaminated surfaces.

- What is the correct storage temperature for perishables? Items that require refrigeration should be stored at or below 40°F (4°C), while frozen items must be kept at 0°F (-18°C) or lower to prevent spoilage.

- How can cross-contamination be avoided? Using separate cutting boards for raw and cooked items, as well as regularly cleaning surfaces and utensils, is key to preventing cross-contamination.

- What should be done if an employee is ill? Ill workers should avoid direct contact with items and, if possible, stay home to prevent spreading any potential pathogens.

- When should protective gloves be worn? Gloves should be worn when handling ready-to-eat items or when cleaning and sanitizing areas that come into contact with consumables.

Addressing these questions ensures that best practices are followed and helps maintain a safe environment for everyone involved. Regular training and staying updated on industry standards are also important for reinforcing these safety measures.

Key Concepts to Pass the Exam

Successfully completing the certification process requires a solid understanding of critical concepts that ensure safety in environments where consumables are prepared and served. Focusing on the right topics will not only help you pass the certification but also ensure that you are equipped with the knowledge necessary to maintain a safe and sanitary workplace. Mastering these concepts is essential for anyone seeking to work in or manage such environments.

Essential Safety Practices

One of the most important areas to focus on is understanding and applying proper safety practices. This includes:

- Sanitation: Regular cleaning and disinfecting surfaces, tools, and equipment is vital to prevent the spread of harmful bacteria.

- Hand Hygiene: Frequent handwashing is crucial, especially after handling raw items or using the restroom, to avoid contamination.

- Personal Protective Equipment (PPE): Knowing when and how to use gloves, masks, and aprons to prevent contact with contaminants.

Temperature and Storage Guidelines

Another key area is understanding the correct storage conditions for different materials. Knowing the right temperature ranges for storage and cooking is crucial to minimize risks. Here are some key points:

- Storage: Ensure perishables are kept at the right temperature–below 40°F (4°C) for refrigeration and 0°F (-18°C) or lower for freezing.

- Cooking: Different foods require specific temperatures to be safely prepared, such as cooking poultry to an internal temperature of 165°F (74°C).

Mastering these concepts will ensure that you understand and can apply the necessary procedures to maintain a safe and hygienic environment. Preparing thoroughly in these areas is essential for passing the certification process.

How to Prepare for the Test

Proper preparation is key to achieving success when it comes to obtaining certification for working in environments that involve the handling and preparation of consumables. Preparing in a structured and focused manner will not only increase your chances of success but also ensure that you have the knowledge and skills to apply in real-world scenarios. Focusing on the right material and understanding the core concepts is essential for mastering the content and passing the certification process.

Here are some practical tips to help guide your preparation:

- Review the Basics: Make sure you have a solid understanding of key safety practices, including proper hygiene, storage guidelines, and temperature controls.

- Use Practice Tests: Familiarize yourself with the format of the questions by taking mock tests. This will help you become more comfortable with the type of material you’ll face.

- Study Relevant Regulations: Ensure you are aware of local health and safety regulations, as these may be included in the test.

- Identify Areas of Weakness: Focus on the areas where you feel less confident. Take extra time to study topics that you find challenging.

- Stay Consistent: Dedicate time each day to study, even if it’s just a few minutes. Regular practice helps reinforce what you’ve learned.

By following these steps, you’ll be well-prepared to tackle the test and demonstrate your understanding of safe practices in the workplace. Remember, preparation is not just about passing the test but about ensuring that you can effectively apply the knowledge in your daily work environment.

What to Expect During the Exam

When it comes time to take the certification assessment, it’s important to understand what the process will entail. The assessment is designed to test your knowledge of essential safety standards and practices required in environments where consumables are prepared and served. Understanding the structure and content of the test will help you feel more confident and prepared for the experience.

The test typically consists of multiple-choice questions that assess your ability to apply key concepts in various scenarios. The questions may cover a range of topics such as hygiene practices, temperature control, and contamination prevention. Here’s what you can expect:

- Time Limit: There will usually be a set time limit to complete the test. Be sure to manage your time wisely and answer questions to the best of your ability.

- Question Format: Most questions will be multiple choice, with one correct answer and a few distractors. Read each question carefully before selecting your answer.

- Content Areas: Expect questions on sanitation, storage guidelines, food safety regulations, and personal hygiene practices.

- Practical Scenarios: Some questions may present real-world scenarios where you’ll need to apply your knowledge to solve problems or make decisions about safety practices.

By familiarizing yourself with the test format and understanding the key concepts, you’ll be better prepared to navigate the assessment confidently. Remember, the goal is to ensure you have the necessary knowledge to maintain a safe environment, so take your time to think through each question carefully.

Essential Safety Practices

In any setting where consumables are handled and prepared, following strict safety procedures is crucial to prevent contamination and ensure the well-being of everyone involved. Proper practices help maintain a hygienic environment, reduce the risk of foodborne illnesses, and ensure that products are safe for consumption. Adhering to these fundamental practices is not only necessary for passing certification but also for creating a safe and healthy workplace.

Here are some key safety practices that must be consistently followed in any setting:

- Hand Hygiene: Frequent handwashing is one of the most important practices. Hands should be washed after using the restroom, touching raw items, or handling waste. Use soap and water, scrubbing for at least 20 seconds.

- Temperature Control: Maintaining the correct temperature for storing, cooking, and serving items is critical to prevent bacterial growth. Refrigerated items should be kept at 40°F (4°C) or lower, while cooked items should reach the proper internal temperature to ensure safety.

- Cross-Contamination Prevention: To avoid the spread of harmful bacteria, it is essential to separate raw and ready-to-eat items. Use different cutting boards, utensils, and storage containers for raw meats, vegetables, and cooked products.

- Proper Cleaning and Sanitizing: Regular cleaning of all surfaces and equipment is necessary to remove any contaminants. Use appropriate sanitizing agents to ensure that everything is thoroughly disinfected and safe to use again.

- Personal Protective Equipment (PPE): Wearing gloves, aprons, and other protective gear helps minimize direct contact with potentially hazardous materials. PPE should be used when handling raw items or cleaning surfaces that may come into contact with consumables.

By incorporating these practices into daily routines, workers can help create a safer environment and ensure the well-being of consumers. Consistent adherence to these safety standards is the foundation of a successful and compliant operation.

Examining Foodborne Illnesses and Prevention

Foodborne illnesses are a significant concern in any environment where consumables are prepared or served. These illnesses are caused by harmful microorganisms such as bacteria, viruses, and parasites that can contaminate products. Understanding how these pathogens spread and how to prevent them is critical to maintaining a safe and healthy environment. Prevention is key to protecting both consumers and workers from the risks associated with improper handling or storage of items.

There are several common pathogens that cause foodborne illnesses, and knowing how to recognize the symptoms and understand their sources is essential for prevention. The most effective preventive measures involve proper hygiene, temperature control, and sanitation practices.

- Common Pathogens: Some of the most common bacteria that cause illnesses include Salmonella, Escherichia coli (E. coli), and Listeria. These bacteria can lead to serious illness if ingested through contaminated products.

- Prevention Strategies: To prevent contamination, proper handwashing, avoiding cross-contamination, cooking products to the right temperature, and storing items at the correct temperature are essential. Ensuring these basic safety practices are followed can significantly reduce the risk of illness.

- Symptoms of Illness: Symptoms may include nausea, vomiting, diarrhea, abdominal cramps, and fever. In severe cases, foodborne illnesses can lead to hospitalization or even death, making prevention even more important.

By staying informed about the risks of foodborne illnesses and consistently applying prevention methods, workers can help safeguard public health and ensure that everyone enjoys a safe experience when consuming products. Regular training and adherence to safety protocols are vital in preventing outbreaks and protecting both consumers and staff.

How to Handle Hazardous Materials

In environments where consumables are prepared, certain materials and substances may pose significant risks if not managed correctly. These hazardous materials can range from cleaning chemicals to raw ingredients that require special attention to ensure safety. Proper handling, storage, and disposal are essential to prevent accidents, contamination, and harm to both workers and consumers. Understanding the correct procedures for dealing with these materials is critical for maintaining a safe workspace.

Here are some essential guidelines for managing hazardous substances effectively:

- Identify Potential Hazards: The first step in safely handling hazardous materials is recognizing potential risks. Common hazardous items include cleaning agents, pesticides, and other chemicals that can cause harm if exposed to the skin, eyes, or ingested.

- Use Personal Protective Equipment (PPE): Always wear the appropriate protective gear when handling dangerous substances. This may include gloves, goggles, aprons, or face shields to prevent direct contact with harmful chemicals or materials.

- Proper Storage: Ensure that hazardous materials are stored in designated, clearly labeled areas, away from food products and other items that could be contaminated. Always follow the manufacturer’s storage instructions to minimize risks.

- Follow Safety Protocols: Be familiar with the safety data sheets (SDS) for each hazardous material. These documents provide detailed information about how to handle, store, and dispose of chemicals safely, as well as first-aid procedures in case of exposure.

- Dispose of Materials Properly: Never dispose of hazardous substances down drains or in regular trash. Follow the local regulations and guidelines for safe disposal to prevent environmental contamination or accidents.

By adhering to these safety guidelines, workers can minimize the risk of accidents and ensure that hazardous materials are handled with the care and attention they require. Regular training and vigilance are necessary to create a safe environment for all involved.

Importance of Proper Handwashing Techniques

One of the simplest yet most effective ways to prevent the spread of harmful microorganisms is through proper hand hygiene. Regular and thorough handwashing is essential in any setting where consumables are handled, as it helps remove dirt, bacteria, and viruses that could lead to contamination. By following the correct techniques, workers can significantly reduce the risk of transmitting harmful pathogens to others and ensure a safer environment for all.

Here are some key steps and considerations to follow for effective handwashing:

- Use the Right Soap: Always use soap and clean, running water. Soap helps break down oils and dirt, making it easier to wash away harmful pathogens.

- Scrub Thoroughly: Be sure to scrub all parts of your hands, including the backs of your hands, between your fingers, and under your nails. This ensures that all areas are free of contaminants.

- Wash for the Right Duration: Wash for at least 20 seconds. This is the recommended amount of time to ensure thorough cleaning, which is crucial for effective hygiene.

- Dry with a Clean Towel: Use a clean paper towel or an air dryer to dry your hands after washing. Avoid touching surfaces with your clean hands to prevent recontamination.

- When to Wash: Hands should be washed before preparing or serving consumables, after using the restroom, after handling waste, or after touching raw materials.

By incorporating these practices into daily routines, individuals can greatly reduce the risk of transferring harmful pathogens. Regular training on proper hand hygiene, along with visible reminders in the workplace, will help reinforce these crucial practices for everyone involved.

Food Storage Guidelines You Must Know

Proper storage of ingredients and prepared items is crucial in any setting that involves the handling of consumables. Incorrect storage practices can lead to contamination, spoilage, or the growth of harmful microorganisms. To maintain safety and ensure the freshness of products, it is essential to follow guidelines that address temperature control, separation of items, and proper handling techniques.

Here are some key storage practices that you must follow:

- Temperature Control: Always store perishable items at the correct temperature to prevent bacterial growth. Refrigerated items should be kept below 40°F (4°C), while frozen items should be stored at 0°F (-18°C) or lower.

- First In, First Out (FIFO): Use the FIFO method when organizing products. This ensures that older items are used before newer ones, preventing items from being forgotten and spoiling.

- Separate Raw and Cooked Items: To avoid cross-contamination, always store raw ingredients separately from ready-to-eat or cooked items. This helps prevent harmful bacteria from spreading between different types of products.

- Airtight Storage: Use sealed containers for storing dry goods and leftovers. Properly sealed containers prevent contamination, keep products fresh, and reduce the risk of pests.

- Proper Labeling: Always label items with the date of receipt or preparation. This helps track the age of ingredients and ensures that nothing is kept beyond its safe usage date.

By following these storage guidelines, you can significantly reduce the risk of contamination and ensure that products remain safe, fresh, and of high quality. Consistent training and attention to detail will help create a safer environment for all involved in handling ingredients or prepared goods.

Temperature Control and Food Safety

Maintaining the proper temperature for ingredients and prepared items is one of the most important factors in preventing the growth of harmful microorganisms. When temperatures are not regulated correctly, bacteria can multiply rapidly, leading to contamination and foodborne illnesses. Both hot and cold items must be stored at specific temperatures to ensure they remain safe for consumption.

Here are some essential temperature control guidelines to follow:

- Cold Storage: Perishable items should be kept at temperatures below 40°F (4°C) to prevent bacterial growth. Always check refrigerator and freezer settings to ensure they are within the correct temperature range.

- Hot Holding: Prepared items that are meant to be served hot should be kept at or above 140°F (60°C). This helps inhibit the growth of harmful pathogens that thrive at lower temperatures.

- Check Temperatures Regularly: Use a reliable thermometer to check both storage and serving temperatures. This ensures that the items are always maintained within the safe range.

- Quick Cooling: When cooling hot items, do so rapidly by placing them in shallow containers or using ice baths. The faster the temperature drops, the safer the product will be.

- Do Not Leave Items at Room Temperature: Never leave perishable items out at room temperature for extended periods. Foods should be kept within the safe temperature range at all times, whether stored or served.

By following these temperature control measures, you can significantly reduce the risk of foodborne illness and ensure that products remain safe, fresh, and nutritious. Regular monitoring and adherence to these practices are vital to maintaining high safety standards in any setting where consumables are prepared or served.

Safe Cooking Methods for Food Handlers

Using the right cooking methods is essential to ensure that ingredients are properly prepared and safe for consumption. Proper cooking not only enhances the flavor and texture of dishes but also eliminates harmful pathogens that could cause illness. The correct application of heat is crucial in killing bacteria, viruses, and parasites that can contaminate raw products.

Here are some key cooking techniques that help ensure safety:

- Thorough Cooking: Always cook ingredients to the recommended internal temperature to destroy harmful microorganisms. Use a food thermometer to verify that the product has reached the necessary heat level throughout.

- Avoid Partial Cooking: Never partially cook items and leave them to finish cooking later. This practice can allow bacteria to multiply during the cooling phase. If necessary, cook all items to completion before serving.

- Use the Right Heat Source: Ensure that your cooking equipment (ovens, stoves, grills) is properly calibrated and can reach the desired temperatures. Using the wrong heat source can result in uneven cooking, which may leave harmful bacteria in the food.

- Steam and Boil: Steaming and boiling are effective cooking methods that use moist heat, which helps ensure thorough cooking, especially for items like vegetables and seafood.

- Grilling and Roasting: For items that require dry heat, grilling and roasting are great methods that allow fats to drain off while ensuring even heat distribution, making the food safe and flavorful.

By following these safe cooking practices, you can significantly reduce the risk of contamination and ensure that dishes are both delicious and safe for consumption. Monitoring temperatures and ensuring proper cooking techniques will help maintain high standards of safety in any setting.

Recognizing Cross-Contamination Risks

Cross-contamination is one of the leading causes of foodborne illness. It occurs when harmful microorganisms are transferred from one surface, item, or substance to another, leading to the contamination of safe items. Recognizing and preventing these risks is crucial for maintaining a clean and safe environment where consumables are handled, prepared, or served.

Here are some common ways cross-contamination can occur and how to mitigate these risks:

| Risk Source | Prevention Method |

|---|---|

| Raw Ingredients | Store raw products separately from ready-to-eat items. Always use separate cutting boards, utensils, and storage containers for raw meats and other ingredients. |

| Unclean Hands | Wash hands thoroughly with soap and water before and after handling any items. Use gloves when handling sensitive ingredients and change them regularly. |

| Improper Equipment Usage | Ensure that equipment such as knives, cutting boards, and countertops are cleaned and sanitized after each use. Use color-coded tools to avoid mixing raw and cooked items. |

| Food Storage | Ensure that raw items are stored in sealed containers, placed on lower shelves in refrigerators, to prevent their juices from dripping onto other foods. |

| Cross-Contact Between Allergen-Free and Allergenic Items | Be diligent about separating allergen-free products from those that may cause reactions. Use separate storage and cooking methods for each to avoid cross-contact. |

By recognizing these risks and taking the necessary steps to prevent cross-contamination, you can significantly reduce the chances of illness and ensure a safe environment for all who consume your products. Vigilance and proper practices play an essential role in food safety.

How to Maintain a Clean Work Area

Maintaining a clean and organized workspace is essential to preventing contamination and ensuring safety. A tidy environment not only promotes efficiency but also helps to reduce the risk of foodborne illnesses. This section will guide you through the necessary steps to keep your work area sanitary and well-maintained.

Key Practices for Cleanliness

- Regular Cleaning: Clean surfaces and equipment frequently, especially after handling raw items. Use appropriate cleaning agents to disinfect and sanitize all contact areas.

- Proper Waste Disposal: Ensure that trash bins are emptied regularly and lined with appropriate waste bags. Avoid overfilling them to prevent spills and odors.

- Organized Storage: Keep all items in their designated spaces to avoid clutter. Label containers and use racks or shelves to store supplies neatly.

- Personal Hygiene: Always wash your hands thoroughly and wear clean clothing. Keep hair tied back and use gloves when necessary to avoid transferring contaminants.

Sanitation and Safety Tips

- Clean and sanitize all surfaces after each use, including counters, tables, and utensils.

- Regularly check and maintain equipment to ensure it is functioning properly and does not pose a hazard.

- Remove food debris from all areas immediately to prevent the buildup of bacteria and pests.

- Store all items at appropriate temperatures to minimize the risk of spoilage or contamination.

By following these simple yet effective practices, you can maintain a safe, organized, and hygienic workspace that supports a high standard of cleanliness and safety for everyone involved.

Benefits of Getting Certified

Obtaining certification in safety and proper practices offers a wide range of advantages, both for individuals and organizations. It ensures that you have the knowledge to make informed decisions, helping you stand out in the workplace and provide a safer environment for everyone involved. This section will explore the key benefits of obtaining such qualifications.

Professional Growth: Certification often leads to career advancement. With a recognized credential, individuals can enhance their resumes, making them more competitive for higher positions and better opportunities. It demonstrates your commitment to personal and professional development, which is highly valued in any industry.

Increased Confidence: When you are certified, you gain a deeper understanding of best practices and procedures. This knowledge boosts confidence in your daily tasks, helping you make the right decisions, prevent mistakes, and reduce risks. Being well-prepared and knowledgeable fosters a sense of assurance in your skills and abilities.

Improved Workplace Safety: Certified professionals are equipped with the tools to manage safety risks effectively. By adhering to regulations and best practices, they help ensure that their work environment is free from hazards, reducing the likelihood of accidents and incidents. This not only safeguards health but also contributes to a more productive and positive workplace.

Enhanced Reputation: Certification reflects your dedication to maintaining high standards, which in turn boosts the reputation of your employer or business. Clients, customers, and partners are more likely to trust and do business with organizations that prioritize safety and quality practices. It shows that you take your responsibilities seriously and are committed to continuous improvement.

Legal Compliance: In many sectors, certification is required by law to comply with health and safety regulations. By being certified, you ensure that your practices align with legal requirements, reducing the risk of fines, penalties, or legal action. Staying updated with the latest standards and regulations helps protect both you and your organization from potential legal issues.

In conclusion, obtaining certification provides numerous benefits, from career advancement and increased confidence to improved safety and enhanced compliance. It is an investment that pays off both professionally and personally, benefiting individuals and organizations alike.

Top Resources for Exam Success

Achieving success in any certification process requires the right tools and resources. With the proper preparation, you can approach any assessment with confidence. This section will highlight the most valuable resources that will help you prepare thoroughly and increase your chances of passing with flying colors.

Study Guides and Textbooks: Comprehensive study materials are essential for understanding the core concepts and ensuring you’re well-versed in the required knowledge. Look for textbooks or study guides that are specifically designed for your certification, as they will provide structured information and practice questions to help reinforce your learning.

- Certified preparation books, often available online or in bookstores

- Official manuals from recognized organizations

- Comprehensive review books that cover all the key topics

Online Courses and Webinars: Many online platforms offer courses specifically tailored to certification preparation. These resources often include video lectures, quizzes, and interactive content that allow for flexible learning at your own pace. Webinars can also be useful, as they provide direct access to experts in the field.

- Websites like Coursera, Udemy, and LinkedIn Learning

- Online webinars hosted by accredited institutions or training centers

- Interactive video lessons to clarify difficult concepts

Practice Tests: One of the most effective ways to ensure you’re prepared is by taking practice tests. These simulate the real test environment, helping you become familiar with the format and question types. Practicing under timed conditions is especially useful to help you manage your time effectively during the actual assessment.

- Free practice exams offered by training centers or websites

- Interactive quizzes that help reinforce knowledge

- Mock exams that simulate the real assessment experience

Study Groups and Forums: Joining a study group or online forum can provide additional support and motivation. Interacting with others who are preparing for the same certification can help you gain different perspectives on challenging topics and clarify any doubts. Group discussions often bring new insights that may be missed in solitary study.

- Online study communities like Reddit or Facebook groups

- In-person or virtual study groups organized by training institutions

- Forums where professionals share tips and advice

Official Websites and Blogs: Many certification programs maintain official websites where you can find important updates, practice questions, and other resources. Additionally, some professionals in the field run blogs or websites that share useful tips and tricks for certification success.

- Official certification bodies’ websites

- Industry blogs and forums offering expert advice

- Certification-specific resources and newsletters

By utilizing a combination of these resources, you will be well-equipped to tackle the challenges of your certification process. A comprehensive approach to preparation ensures that you not only pass the test but excel in it, setting you up for future success.