Effective calculation techniques are essential in the field of water treatment, where precise measurements and formulas help ensure the proper functioning of various processes. These techniques are vital for professionals who manage complex systems designed to treat and process water efficiently.

To achieve optimal performance, it’s crucial to grasp the fundamentals of how different parameters, such as flow rates, chemical doses, and retention times, interact within a treatment plant. Proper calculations ensure that these factors are balanced, contributing to both cost-effectiveness and environmental sustainability.

In this section, we will explore key concepts and practical approaches that guide the calculation process in water treatment facilities. By understanding how to apply these techniques, you can tackle various challenges that arise in the field and improve the overall efficiency of your system.

Understanding Water Treatment Calculations

In the field of water processing, accurate computation is crucial for the successful design, operation, and management of treatment systems. Professionals rely on these calculations to maintain optimal system performance and ensure that the treated water meets the required standards. These evaluations involve several variables, all of which must be carefully balanced to achieve the desired outcomes.

The core of these evaluations involves determining key factors such as chemical usage, flow rates, retention times, and sludge handling. Understanding how to calculate these elements is essential for professionals to ensure that all processes operate within the intended parameters, avoiding potential inefficiencies or environmental issues.

- Flow rates and their impact on treatment efficiency

- The role of chemical dosages in purification processes

- How to determine the correct retention time for different stages

- Evaluating the volume of solids produced during treatment

Each of these factors requires careful consideration, as even small mistakes in calculation can lead to large-scale inefficiencies or system malfunctions. Therefore, mastering the techniques for accurate calculations is key for professionals in the field.

Common Calculation Methods in Water Treatment

In water treatment, there are several key approaches used to determine the necessary parameters for effective system operation. These methods are designed to ensure that processes such as purification, filtration, and chemical dosing are executed efficiently. By understanding the appropriate calculation techniques, operators can optimize system performance, reduce waste, and prevent operational errors.

Here are some of the most commonly used methods in the industry:

| Method | Description |

|---|---|

| Flow Rate Calculation | Used to determine the volume of water passing through a system per unit of time, critical for controlling treatment processes. |

| Chemical Dosage Calculation | Involves calculating the correct amount of chemicals needed for effective treatment, based on water characteristics. |

| Hydraulic Retention Time (HRT) | Measures the amount of time water stays in a treatment unit, impacting treatment efficiency. |

| Sludge Volume Calculation | Helps determine the amount of sludge produced, which is essential for managing waste disposal and resource recovery. |

These methods form the foundation of effective treatment management. Each calculation plays a significant role in ensuring that all components work together seamlessly, contributing to both the efficiency of the system and its environmental impact.

Key Formulas for Water Treatment Calculations

Accurate formulas are essential tools in the field of water processing, as they provide the foundation for many critical calculations. These formulas help professionals determine various factors, such as chemical dosing, flow rates, and the efficiency of treatment processes. Understanding how to use these formulas is crucial for ensuring that systems operate within their optimal parameters.

Some of the most important formulas used in water treatment calculations include:

- Flow Rate Calculation: Flow rate (Q) = Volume (V) / Time (T) – This formula determines how much water flows through a system within a given time period.

- Chemical Dosage: Dosage (D) = (Flow rate (Q) × Required concentration (C)) – Helps calculate the exact amount of chemical needed based on water flow and desired treatment level.

- Hydraulic Retention Time (HRT): HRT = Volume of tank (V) / Flow rate (Q) – This measures how long the water remains in a treatment unit, affecting treatment efficiency.

- Sludge Volume Index (SVI): SVI = (Volume of settled sludge (V) / MLSS concentration (M)) × 1000 – Used to evaluate the characteristics of the sludge produced in the treatment process.

These fundamental formulas are used to assess and control the performance of various treatment stages. By mastering these calculations, professionals can ensure that the system operates efficiently, with minimal resource usage and maximum environmental benefits.

Step-by-Step Guide to Solving Challenges

When dealing with complex calculations in water treatment, it is essential to approach each task systematically. Breaking down the process into manageable steps allows professionals to tackle each aspect with precision and avoid errors. A clear, structured method helps ensure that all variables are accounted for and that the calculations are accurate.

Follow these basic steps to solve common challenges encountered in water treatment processes:

- Identify the Given Information – Start by carefully reviewing the problem and extracting all relevant data such as flow rates, concentrations, or tank volumes.

- Determine What Needs to Be Calculated – Understand what you are trying to find. Whether it’s chemical dosage, retention time, or sludge volume, clarify the goal before proceeding.

- Select the Appropriate Formula – Choose the right formula based on the data provided and the desired outcome. Ensure that all necessary parameters are included.

- Plug in the Values – Substitute the known values into the formula, paying attention to units and ensuring consistency.

- Perform the Calculation – Carry out the necessary mathematical operations, double-checking each step for accuracy.

- Review the Result – Once the calculation is complete, verify the result by comparing it with expected values or using alternative methods if possible.

By following this step-by-step approach, you can efficiently solve most challenges in water treatment, ensuring that systems run smoothly and meet required standards.

Importance of Flow Rate in Calculations

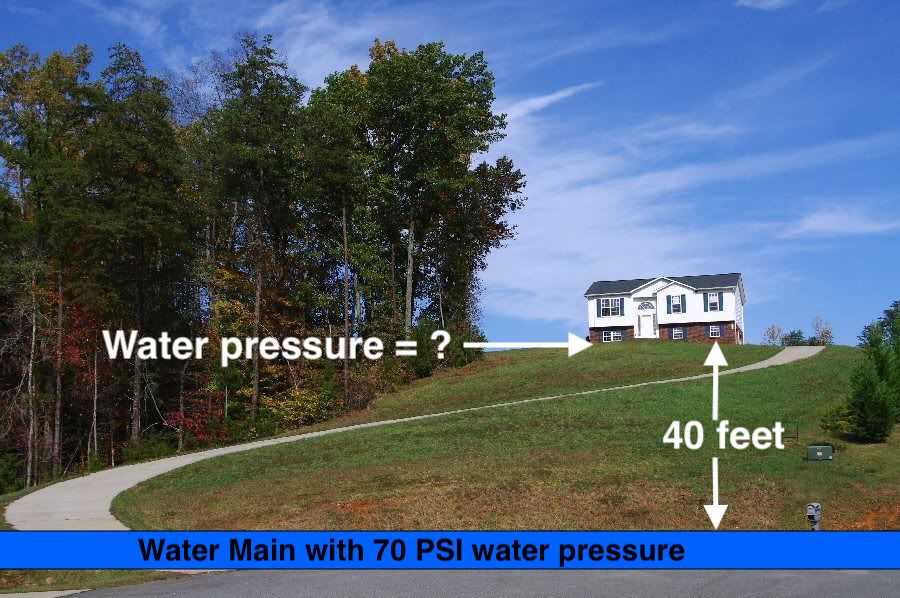

Flow rate is a critical parameter in many calculations related to water treatment systems. It refers to the volume of liquid that moves through a specific point or system over a given period. This value directly impacts how treatment processes are designed and optimized, making it essential for engineers and operators to understand and control.

Accurate flow rate measurements allow professionals to determine the necessary chemical doses, calculate retention times, and assess the overall efficiency of the system. If the flow rate is too high or too low, it can lead to insufficient treatment or overuse of resources, both of which can result in costly inefficiencies or regulatory violations.

Furthermore, flow rate plays a vital role in the design of treatment units such as filters, reactors, and clarifiers. It helps determine the size and capacity of these units to ensure they can handle the expected load without compromising performance. Maintaining the right flow rate is, therefore, essential for ensuring that the entire system functions as intended.

Units and Conversions in Water Treatment Calculations

In water treatment, precise measurements are essential, and understanding the units used in calculations is critical for accuracy. Various units are employed to quantify parameters such as flow rate, chemical dosage, volume, and concentration. Correctly converting between these units ensures that calculations remain consistent and reliable across different systems and equipment.

Commonly used units include liters, gallons, cubic meters, and milliliters for volume; grams, kilograms, or pounds for mass; and seconds, minutes, or hours for time. Each of these units plays a role in determining the proper amount of chemicals, the flow capacity of treatment tanks, or the efficiency of a filtration process. Conversions between units are often necessary when working with different system standards or when comparing data from various sources.

By mastering unit conversions, professionals can confidently perform calculations that involve different measurement systems, ensuring the accurate design and operation of water treatment processes. This practice helps prevent errors that could lead to under-treatment or overuse of resources.

How to Calculate Chemical Dosing

Accurate chemical dosing is essential for effective treatment in water systems. Adding the correct amount of chemicals ensures that contaminants are properly removed without wasting resources or causing harm to the environment. The right dosage depends on various factors, including water volume, flow rate, and the specific treatment goals.

To calculate the appropriate chemical dose, follow these general steps:

- Identify the Treatment Requirement – Determine the specific chemical needed and the desired concentration or effect (e.g., disinfection, coagulation).

- Measure the Flow Rate – Find the flow rate of water entering the treatment system, as this will directly influence the amount of chemical required.

- Calculate the Dosage – Use the formula: Dosage (mg/L) = (Chemical demand × Flow rate) / 1,000, adjusting the values as needed based on system units.

- Adjust for System Size – Multiply the calculated dosage by the system’s total volume if necessary to determine the full quantity of chemical to add.

By following these steps, you can ensure that the correct chemical amount is used for optimal treatment without exceeding required levels. This precision helps maintain system efficiency, prevent chemical waste, and meet environmental standards.

Understanding BOD and COD Calculations

BOD (Biochemical Oxygen Demand) and COD (Chemical Oxygen Demand) are two key indicators used to assess the quality of water. These values help determine the amount of oxygen required to break down organic substances in the water. Both measurements are vital for evaluating the effectiveness of treatment processes and the impact of pollutants on the environment. Understanding how to calculate these parameters is crucial for ensuring proper water management and regulatory compliance.

To calculate BOD and COD, the following general steps are involved:

- BOD Calculation: This measurement indicates the amount of oxygen consumed by microorganisms to decompose organic matter in a water sample over a specific period, typically five days at 20°C. The formula is BOD (mg/L) = (Oxygen demand before incubation – Oxygen demand after incubation).

- COD Calculation: This value measures the total oxygen demand, including both biodegradable and non-biodegradable substances. COD is determined by using a strong oxidizing agent to break down the organic material, and the formula is COD (mg/L) = (Oxygen consumed during reaction) × Conversion factor.

Both BOD and COD calculations provide valuable insights into water quality, but they differ in what they measure. BOD focuses on the biodegradability of organic matter, while COD measures the total oxygen demand, including materials that may not be biologically degradable. These calculations help determine the required treatment level to maintain safe water standards.

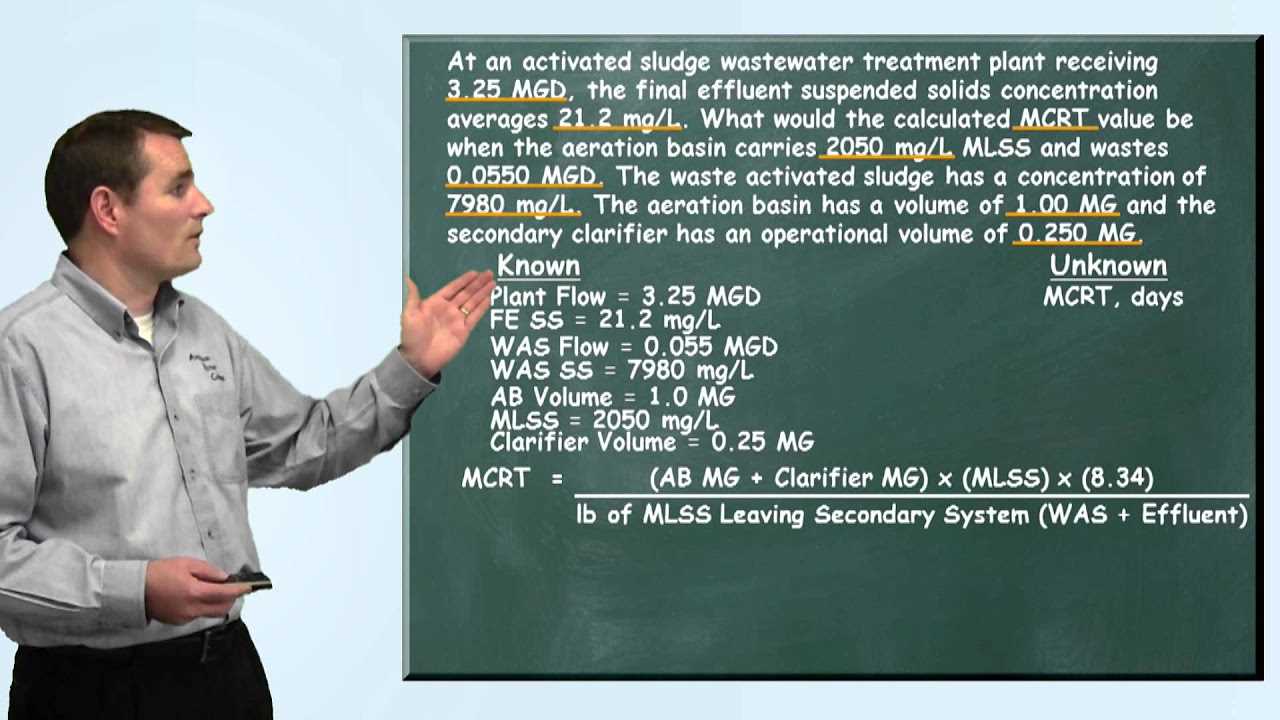

Calculating Sludge Volume and Treatment

The volume of sludge produced during water treatment processes is an important parameter to monitor, as it directly affects system efficiency and disposal strategies. The quantity of sludge generated can impact operational costs, space requirements for storage, and the effectiveness of treatment methods. Accurate calculations ensure that treatment facilities are appropriately sized and managed, and that environmental regulations are met.

To calculate the sludge volume, it is essential to consider factors such as the influent flow rate, the concentration of suspended solids, and the efficiency of the treatment process. A common formula for estimating sludge volume is:

- Sludge Volume (m³/day) = (Flow rate (m³/day) × Suspended solids concentration (mg/L)) / 1000

Once the sludge volume is determined, the treatment process for the sludge itself must also be considered. This can involve techniques like thickening, dewatering, or stabilization, depending on the characteristics of the sludge and the final disposal method. Each treatment method requires different calculations to ensure that the sludge is handled safely and efficiently.

By accurately calculating both the volume and the treatment requirements for sludge, facilities can optimize their operations, minimize costs, and comply with environmental standards, while also improving the overall sustainability of their processes.

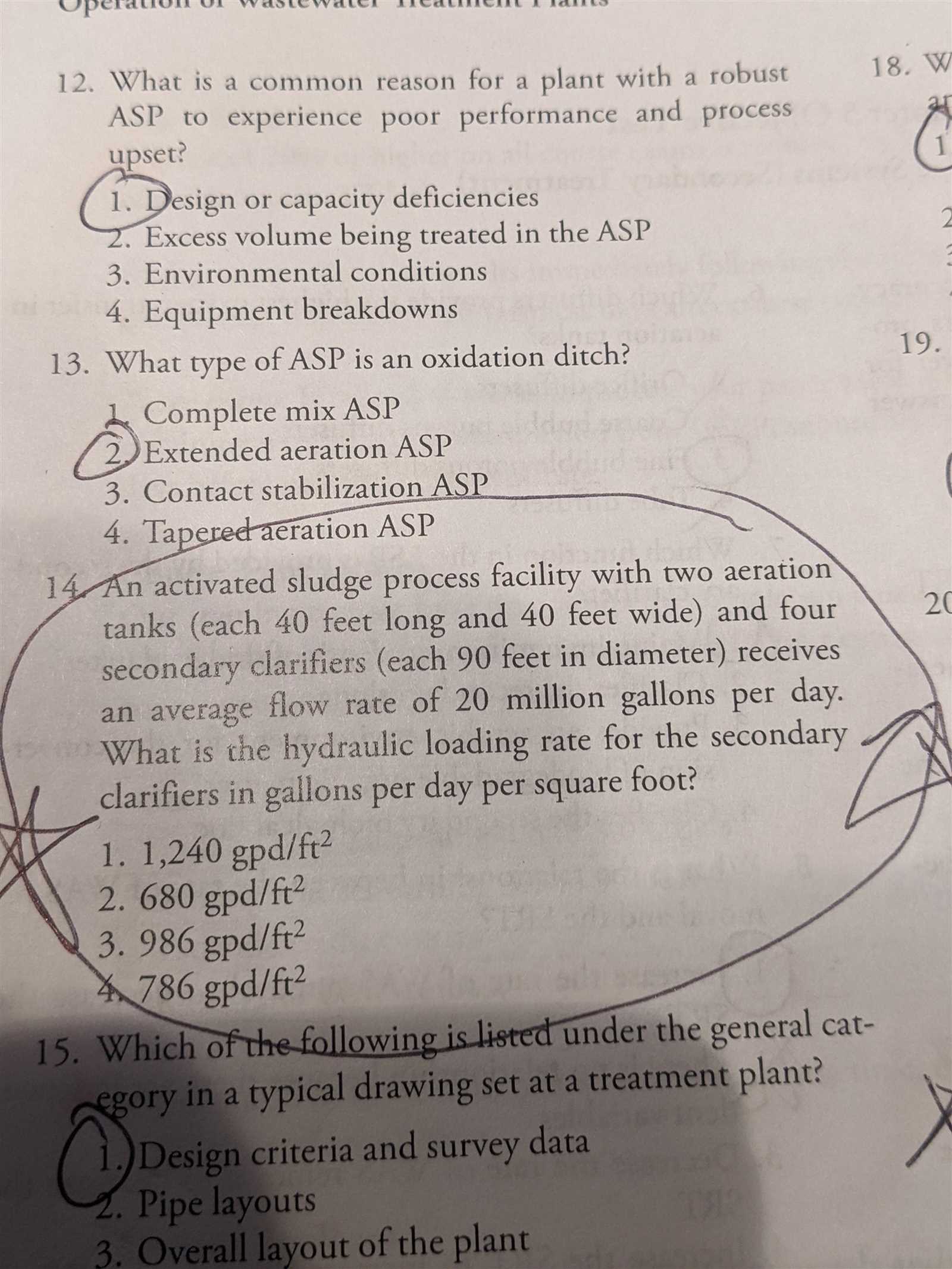

Designing Water Treatment Systems with Calculations

Designing an efficient treatment system requires precise planning and calculation to ensure that the facility can handle the required volume of water while meeting regulatory standards. Calculations are integral to determining the size, capacity, and performance of various components within the system. Engineers and operators use these calculations to ensure the proper flow, chemical dosages, and treatment times are achieved for optimal results.

Key Considerations in System Design

When designing a treatment system, there are several critical factors that must be considered. These include:

- Flow Rate – Understanding the flow rate helps determine the required size of pipes, tanks, and pumps.

- Retention Time – Calculating the time water remains in treatment units is essential for achieving the desired treatment efficiency.

- Chemical Dosage – Proper dosing is essential for effective treatment without overusing chemicals.

- Load Calculations – Estimating the organic or inorganic load helps determine the appropriate treatment processes and equipment.

Designing Specific Components

Once the general system requirements are understood, individual components need to be designed and sized accurately. Some examples of how calculations are applied include:

- Clarifiers – Calculating the surface area and depth of clarifiers is essential for effective sedimentation and sludge removal.

- Filters – Determining the filter surface area based on the flow rate and expected loading ensures optimal filtration performance.

- Reactors – Reactor volume and retention time calculations are key for ensuring that chemical reactions occur effectively.

By leveraging precise calculations, engineers can ensure that all components of the system are appropriately sized and designed to meet operational needs, optimize resource use, and comply with environmental standards.

Balancing Flow and Treatment Efficiency

Achieving the right balance between the flow of water through a treatment system and its overall effectiveness is essential for maintaining optimal performance. Too much flow can overwhelm treatment units, reducing their ability to treat water efficiently. Conversely, too little flow can lead to underutilization of system capacity. Ensuring a steady, manageable flow while optimizing treatment processes is key to both meeting regulatory standards and minimizing operational costs.

To maintain this balance, several factors need to be considered:

- Flow Control – Accurately measuring and adjusting the flow rate ensures that each treatment step can function within its design parameters.

- Capacity Matching – Treatment units must be sized to handle peak flow rates without compromising treatment efficiency.

- Retention Time – Sufficient time for the treatment process must be maintained, ensuring that contaminants are effectively removed without the system being overloaded.

In practice, fine-tuning flow rates requires continuous monitoring and adjustment to account for variations in water volume, quality, and external conditions. Operators often use advanced control systems to maintain this balance, ensuring that all components of the treatment process are performing efficiently and effectively.

Understanding Hydraulic Retention Time

The amount of time that water stays within a treatment unit, such as a tank or reactor, plays a crucial role in determining the efficiency of the treatment process. This time period, known as retention time, directly impacts the ability of the system to remove contaminants and ensure effective treatment. Adequate retention time allows for chemical reactions, biological processes, and physical separation to occur, leading to better water quality outcomes.

How Retention Time Affects Treatment Performance

The relationship between retention time and treatment efficiency is vital for ensuring that contaminants are adequately processed before the water is discharged or further treated. Shorter retention times can lead to insufficient treatment, while longer times may result in higher costs or unnecessary use of resources. The ideal retention time depends on factors such as:

- Type of Treatment – Different methods, like sedimentation or filtration, require varying amounts of time to achieve optimal results.

- Contaminant Load – The concentration of pollutants in the influent affects how long the water must stay in the treatment unit.

- System Design – The size and configuration of tanks or reactors will determine how efficiently flow is managed and how long water remains in the system.

Calculating Hydraulic Retention Time

To calculate hydraulic retention time, the following formula is typically used:

- Retention Time (hrs) = Volume of the Treatment Unit (m³) / Flow Rate (m³/hr)

By understanding and controlling hydraulic retention time, operators can optimize the treatment process, ensure effective contaminant removal, and minimize operational costs. Continuous monitoring of this parameter is essential for maintaining system efficiency and meeting environmental standards.

Using Wastewater Data for Problem Solving

Data collected during the treatment process plays a key role in identifying issues, optimizing operations, and making informed decisions. By analyzing relevant metrics, operators can pinpoint inefficiencies, troubleshoot issues, and improve system performance. Accurate data allows for a better understanding of how each component of the treatment system is functioning and helps in making adjustments when necessary.

Some of the critical data points commonly used in this context include:

- Flow Rates – Monitoring the volume of water moving through the system ensures that each step of the treatment process is properly scaled and functioning as designed.

- Chemical Dosage – Recording the amount of chemicals used in the treatment process is essential for maintaining proper balance and ensuring effective treatment without overuse.

- Concentration of Contaminants – Regular measurements of pollutants in the influent and effluent help track treatment efficiency and identify areas for improvement.

By evaluating trends in these data points, operators can identify underlying issues, predict potential challenges, and take corrective action before problems escalate. In addition, this data can be used to model different treatment scenarios, allowing for optimization without the need for expensive or time-consuming trial and error. Ultimately, effective data analysis helps streamline operations, ensure compliance, and improve environmental outcomes.

Common Mistakes in Wastewater Calculations

Even the most experienced operators can make errors when performing calculations related to treatment systems. These mistakes can lead to inefficiencies, higher operational costs, and, in some cases, environmental violations. Understanding the common missteps and how to avoid them is crucial for ensuring accurate results and effective system performance. Below, we will explore some of the most frequent mistakes encountered during calculations and how to correct them.

1. Incorrect Flow Rate Measurements

Flow rate is one of the most critical factors in treatment system calculations. A common mistake occurs when operators fail to account for variations in flow, such as seasonal changes or inconsistent input. Inaccurate flow rate readings can lead to improper chemical dosing, insufficient treatment, or even system overloads. It is essential to regularly calibrate flow meters and consider fluctuating conditions to ensure precise measurements.

2. Misunderstanding Conversion Factors

Another common mistake arises when operators incorrectly convert units during calculations. Whether converting between liters and cubic meters or gallons and liters, using the wrong conversion factor can lead to significant errors in dosage, retention time, and other important parameters. Always double-check unit conversions and be familiar with the most common ones used in the industry.

| From | To | Conversion Factor |

|---|---|---|

| Gallons | Cubic meters | 1 gallon = 0.003785 m³ |

| Cubic meters | Liters | 1 m³ = 1000 liters |

| Liters | Milliliters | 1 liter = 1000 milliliters |

By ensuring that the correct conversion factors are applied, operators can avoid cascading errors in subsequent calculations. Always verify the conversion before proceeding to the next step in the calculation process.

3. Failing to Account for System Changes

Another mistake frequently made is not accounting for changes in the system, such as upgrades, maintenance, or changes in influent quality. When a system undergoes alterations, recalculating key parameters is necessary to maintain optimal treatment performance. Neglecting these adjustments can result in calculations based on outdated data, leading to ineffective treatment or overuse of resources.

By recognizing these common mistakes and taking steps to avoid them, operators can ensure that their calculations are accurate, cost-effective, and environmentally sound.

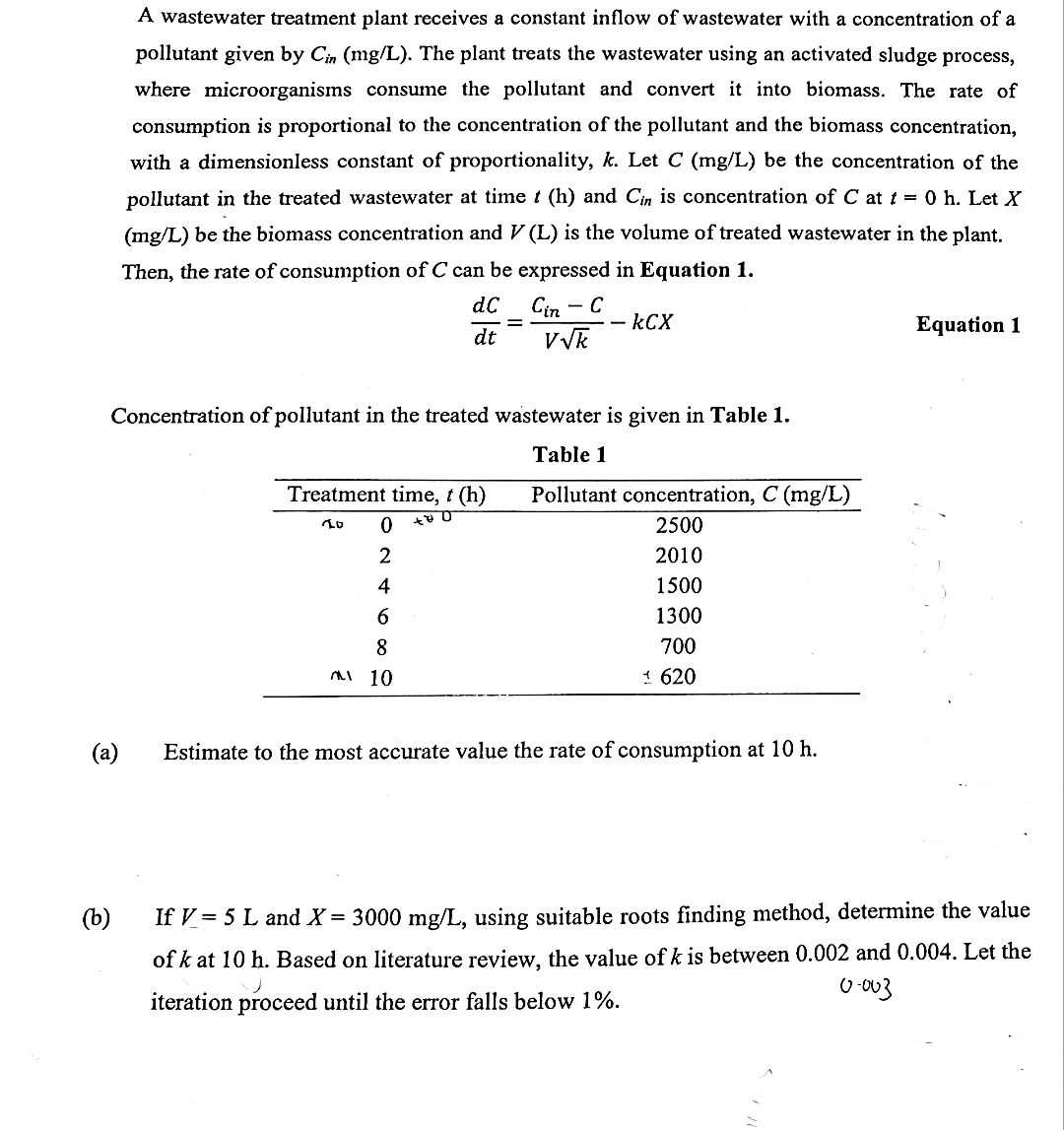

Advanced Math in Wastewater Engineering

In the field of treatment system design and management, complex calculations are often required to ensure systems perform efficiently and meet regulatory standards. These advanced techniques go beyond basic arithmetic and involve intricate modeling and sophisticated equations that account for various dynamic factors. Professionals in this area must be well-versed in applying advanced principles to optimize performance and avoid potential failures.

Several advanced concepts play a pivotal role in the analysis and optimization of treatment facilities:

- Dynamic Modeling: This involves simulating the behavior of treatment processes under varying conditions to predict system performance. It helps in evaluating the impact of different influent qualities and flow rates over time.

- Reaction Kinetics: The rate at which chemical or biological reactions occur is essential for designing reactors and selecting appropriate treatment methods. Complex rate equations are used to determine how quickly contaminants are removed.

- Hydraulic Modeling: Predicting the movement of water through treatment units or pipelines requires applying fluid dynamics. Advanced hydraulic models are used to optimize the layout and design of facilities.

These techniques help engineers make critical decisions regarding system sizing, chemical dosing, and energy consumption, among others. Properly applying advanced principles ensures that treatment processes are both effective and cost-efficient, while also complying with environmental regulations.

Key Advanced Techniques in Treatment Design

- Computational Fluid Dynamics (CFD): A method used to simulate fluid flow patterns within reactors and pipelines, helping to optimize system design and minimize energy loss.

- Activated Sludge Modeling: This mathematical model helps to predict the behavior of microorganisms in treatment systems, determining the appropriate conditions for efficient organic matter removal.

- Energy Balance Calculations: In order to minimize energy consumption, engineers use advanced energy balance equations to model the energy requirements of different treatment stages.

Mastering these advanced mathematical techniques is crucial for engineers and operators aiming to improve the efficiency and sustainability of treatment systems. These tools allow for a more precise understanding of how various factors interact and contribute to system performance.

Practical Examples of Wastewater Problems

In engineering and environmental management, real-world challenges often arise that require precise calculations to ensure effective system design and optimal performance. These scenarios can range from determining the right treatment process to assessing how various factors like flow rate, chemical dosing, or system configuration affect the overall efficiency. By applying theoretical knowledge to actual situations, professionals can solve issues and enhance treatment operations.

Here are a few practical examples illustrating how different variables can influence treatment systems:

Example 1: Calculating Required Sludge Volume

In one case, engineers need to determine the required volume of sludge removal from a treatment tank based on influent characteristics and desired effluent quality. By using known concentrations and flow rates, the necessary sludge volume can be estimated. This ensures that the tank operates within its designed limits and prevents overflow or insufficient removal.

Example 2: Determining Chemical Dosing for Treatment

Another scenario involves calculating the amount of chemicals needed for proper treatment. Given the influent concentration of pollutants, operators can use dosing formulas to calculate the required chemical amounts. This helps achieve the desired treatment level while minimizing waste and costs.

These examples demonstrate the importance of applying calculations in real-world settings to ensure that systems are running effectively, meeting compliance standards, and optimizing resource use.