Ensuring safety in any workplace, especially those handling consumables, is crucial for protecting both employees and customers. There are specific guidelines and principles that professionals must adhere to, ensuring hygiene and preventing contamination. Understanding these standards is key to maintaining a safe and healthy environment for everyone involved.

Acquiring the right knowledge is not only beneficial but required in many industries, where employees must demonstrate competency in maintaining cleanliness and proper procedures. This knowledge is often assessed through examinations that focus on the essential safety rules, protocols, and practices relevant to handling products that will be consumed by others.

Passing these evaluations not only helps ensure compliance with regulations but also boosts confidence in performing daily tasks while minimizing risks. In this guide, we’ll explore the critical topics and methods to approach these evaluations, offering valuable insight and practical tips to help individuals succeed in their certification journey.

Food Safety Certification Evaluation Insights

In many industries, ensuring proper safety practices when working with consumables is a legal and ethical requirement. Professionals are often required to demonstrate their understanding of essential hygiene and safety protocols through an evaluation. This section offers valuable insights to help individuals prepare effectively and pass these assessments with confidence, ensuring they can maintain a safe environment for both employees and customers.

Key Concepts to Focus On

To succeed in the evaluation, it’s important to focus on the core principles that govern safe practices in the workplace. These principles include proper sanitation techniques, the prevention of cross-contamination, personal hygiene, and the correct handling of equipment and consumables. Understanding these concepts thoroughly is crucial for performing well in any certification evaluation.

Effective Study Strategies

Preparing for such evaluations requires an organized approach. One of the most effective methods is to break down the topics into manageable sections and study each thoroughly. Practice quizzes and mock evaluations can also help reinforce knowledge and increase retention. Additionally, reviewing common mistakes and focusing on frequently tested areas can enhance your readiness and boost your chances of success.

Understanding the Safety Certification Evaluation

In many professions, especially those involving consumable products, demonstrating knowledge of safety and hygiene practices is essential. Professionals must pass an evaluation to ensure they are capable of preventing contamination, maintaining cleanliness, and following industry regulations. Understanding the format and structure of this evaluation is key to preparing effectively and increasing the chances of success.

The evaluation typically consists of multiple-choice questions that test a broad range of topics. The primary goal is to assess whether candidates are familiar with safety protocols and can apply them in real-world situations. It is important to be aware of the types of questions that might be included, as well as the areas they focus on.

Common Areas Covered in the Evaluation

- Sanitation and Hygiene – Proper cleaning methods, handwashing, and maintaining a clean working environment.

- Cross-Contamination Prevention – Understanding how to avoid mixing raw and cooked products, and managing allergens.

- Temperature Control – Safe food storage and handling temperatures to avoid bacterial growth.

- Personal Safety – The importance of protective gear and hygiene habits to maintain a safe working space.

How to Approach the Evaluation

Familiarity with the structure of the evaluation can make it less daunting. Here are a few strategies to prepare:

- Study the Core Topics – Focus on the most frequently tested concepts, such as sanitation, personal hygiene, and temperature control.

- Take Practice Exams – Simulate the evaluation experience by taking practice exams online or using study guides.

- Review Common Mistakes – Understand which questions or topics are often challenging, and review them carefully.

Key Requirements for Passing the Evaluation

Successfully completing the certification process requires meeting certain criteria that demonstrate an individual’s knowledge and ability to maintain safety and hygiene in environments dealing with consumables. The evaluation is designed to assess the understanding of important practices such as cleanliness, proper handling techniques, and regulatory compliance. Meeting these requirements ensures that individuals are prepared to contribute to a safe workplace.

Essential Knowledge Areas

To pass, candidates must be well-versed in several core areas that are critical to maintaining safety standards. These include:

- Sanitation Techniques – Understanding proper cleaning methods and maintaining hygiene standards.

- Cross-Contamination Prevention – Awareness of how to avoid mixing raw and cooked products and managing allergens.

- Proper Temperature Control – Knowledge of safe storage and handling practices to prevent bacterial growth.

- Personal Hygiene Practices – Recognizing the importance of clean clothing, handwashing, and proper grooming to avoid contamination.

Practical Application and Compliance

Beyond theoretical knowledge, passing the evaluation also requires the ability to apply these principles in practical situations. Compliance with local and industry regulations is essential for ensuring that safety procedures are followed correctly. Being able to demonstrate an understanding of these practical requirements is crucial for passing the evaluation and obtaining certification.

Common Questions in Safety Certification Exams

When preparing for the certification evaluation, it’s helpful to understand the types of questions commonly asked. These questions are designed to assess a candidate’s knowledge of safe practices, hygiene standards, and proper procedures in environments where consumables are handled. Familiarity with the types of questions can improve preparation and boost confidence.

The questions typically cover a broad range of topics, from cleaning protocols to the correct handling of products. Here are some examples of the most frequently asked questions:

- What is the proper way to store perishable items? – Understanding temperature control and the importance of refrigeration.

- How should workers prevent contamination during meal preparation? – Identifying safe handling techniques to avoid cross-contact between raw and cooked ingredients.

- What are the correct handwashing procedures? – Recognizing the importance of hygiene in preventing the spread of bacteria and illnesses.

- What personal protective equipment (PPE) should be used? – Knowing when and how to wear gloves, aprons, and other protective gear.

Being familiar with these types of questions will help candidates approach the evaluation with confidence, knowing what to expect and how to answer accurately.

Study Tips for Safety Certification

Preparing for a certification evaluation requires a focused approach and effective study techniques. Success in the assessment depends on understanding key safety principles and being able to apply them in real-world scenarios. Here are some practical study tips to help you prepare thoroughly and confidently.

Effective Study Techniques

- Break Down the Topics – Divide the material into manageable sections, focusing on one topic at a time. This makes studying less overwhelming and helps retain information better.

- Use Study Guides – Use reputable study guides or online resources specifically designed for certification preparation. These resources often provide concise explanations and practice questions.

- Take Practice Quizzes – Reinforce your knowledge by taking practice quizzes. These can help you become familiar with the type of questions asked and identify areas where you may need more review.

- Review Common Mistakes – Pay attention to frequently tested concepts or areas that often lead to confusion. By reviewing these, you can avoid common pitfalls and improve your accuracy.

Creating a Study Schedule

Establishing a study schedule is essential for consistent progress. Here’s a recommended approach:

- Set Specific Goals – Define clear, achievable goals for each study session, such as mastering a particular topic or completing a set number of practice questions.

- Allocate Time Wisely – Dedicate specific time blocks each day for studying, ensuring you cover all topics before the evaluation date.

- Take Regular Breaks – Studying for long periods without breaks can lead to burnout. Schedule short breaks to stay focused and retain information more effectively.

By following these study tips and staying committed, you’ll increase your chances of passing the certification evaluation and gaining the necessary skills to work safely in your environment.

Safety Knowledge for the Certification Evaluation

In order to pass the certification evaluation, it is essential to have a solid understanding of key safety principles. This knowledge is critical for ensuring that practices related to cleanliness, hygiene, and product handling are performed correctly, minimizing the risk of contamination and promoting a safe environment for everyone. Candidates should focus on grasping the core concepts and procedures that govern a safe working environment.

Key Topics to Focus On

The following areas are often emphasized in the certification evaluation:

- Sanitation and Hygiene – The importance of maintaining clean workspaces, proper handwashing, and using appropriate cleaning agents to prevent bacterial growth.

- Cross-Contamination Prevention – Understanding how to prevent the mixing of raw and cooked products, and managing allergens to avoid health risks.

- Temperature Control – Knowing the correct storage and handling temperatures for products to ensure that they remain safe for consumption.

- Personal Hygiene Practices – Recognizing the significance of clean clothing, gloves, and other protective measures to reduce contamination.

Practical Applications of Safety Knowledge

It’s not enough to simply memorize safety procedures; candidates must also be able to apply this knowledge in real-world scenarios. Being able to recognize when and how to implement these safety measures will not only help you pass the evaluation but also ensure a safe and hygienic environment in your workplace.

Top Mistakes to Avoid in the Evaluation

When preparing for the certification evaluation, it’s easy to make mistakes that can impact your performance. These errors often stem from misunderstandings of key concepts or rushing through questions without careful consideration. Being aware of the most common pitfalls can help you avoid them and increase your chances of success.

Here are some of the top mistakes to watch out for during the evaluation:

- Rushing Through Questions – One of the biggest mistakes is rushing to complete the evaluation. It’s important to take your time and carefully read each question to ensure you’re providing the most accurate response.

- Ignoring Important Details – Many questions include key details that are critical for choosing the right answer. Pay close attention to terms such as “always,” “never,” or “only” to avoid making incorrect assumptions.

- Overlooking Regulatory Guidelines – Some candidates neglect to study local regulations or industry-specific requirements. These guidelines are often included in the evaluation and must be understood to answer questions correctly.

- Not Reviewing Mistakes – Failing to review mistakes or unclear answers before submitting can cost valuable points. Take the time to double-check your responses and ensure you haven’t missed anything.

Avoiding these common mistakes will help you approach the evaluation with confidence and improve your chances of success. Being mindful of the process and staying focused on the key concepts will ensure that you’re well-prepared for the certification.

How to Prepare for the Certification Evaluation

Preparing for the certification evaluation involves more than just reviewing basic concepts. It requires a thorough understanding of essential safety and hygiene practices, along with the ability to apply this knowledge effectively in real-life situations. A strategic approach to studying and practice will help ensure that you’re fully prepared for the evaluation process.

Here are some steps to help you prepare for the certification evaluation:

| Preparation Step | Description |

|---|---|

| Study Key Concepts | Review the most important safety practices, such as cleanliness, cross-contamination prevention, and temperature control. Focus on understanding how these concepts are applied in various environments. |

| Practice with Sample Questions | Familiarize yourself with the types of questions that will be asked. Practice answering sample questions to build confidence and test your knowledge. |

| Review Local Regulations | Make sure you understand the relevant regulations that govern safety practices in your area. These may vary depending on location and industry. |

| Take Mock Evaluations | Participate in mock evaluations or quizzes to simulate the real experience. This helps identify areas where you may need to improve and allows you to practice under timed conditions. |

| Focus on Application | It’s important to know not just the theory but how to apply it in a practical setting. Think about how each concept works in the context of day-to-day tasks. |

By following these preparation steps, you will ensure that you’re ready for the certification evaluation and have the knowledge necessary to demonstrate competence in safety practices. Proper preparation will boost your confidence and help you pass with ease.

Importance of Safe Handling Practices

Proper management of materials and supplies in environments that prepare consumables is critical to preventing contamination and ensuring public health. It is essential that safety measures, such as cleanliness, proper storage, and handling techniques, are followed to protect individuals from harmful pathogens. Understanding and implementing these practices plays a key role in reducing the risk of illness and ensuring the integrity of products throughout the preparation and delivery process.

When safety protocols are neglected, there is an increased risk of harmful agents being introduced, potentially leading to serious health consequences. Such lapses can harm consumers, damage an organization’s reputation, and result in costly legal and regulatory issues. Consistent application of safety measures helps create a secure environment for both employees and customers, supporting long-term trust and business success.

By focusing on maintaining high hygiene standards and safe practices, organizations can enhance consumer confidence, protect public health, and comply with necessary regulations, all of which are essential for operating a successful and reputable service.

How to Pass the Certification Evaluation Easily

Successfully completing the certification evaluation requires more than just memorizing facts. It involves understanding key principles and being able to apply them in practical scenarios. The goal is to demonstrate a solid grasp of safety protocols and regulations while managing risks and maintaining high standards of hygiene. By following a clear and structured approach to preparation, passing the evaluation can be much simpler and stress-free.

Focus on Key Concepts

To ensure success, focus on the most important topics that are frequently covered. Review essential principles such as cleanliness, temperature control, cross-contamination prevention, and personal hygiene practices. Understanding how these principles apply to everyday tasks will help you recognize the right answers during the evaluation.

Practice with Sample Questions

Another effective method is to practice with sample questions that resemble those found in the evaluation. Familiarizing yourself with the format of the questions will increase your confidence and help you identify areas where you may need further review. Practice regularly and review explanations for any incorrect responses to ensure you understand the reasoning behind the right answers.

By focusing on these strategies, you can reduce the likelihood of surprises during the certification process and approach it with the confidence needed to succeed.

Essential Safety Topics to Study

When preparing for a certification evaluation in safety practices, focusing on the key areas that impact health and hygiene is critical. Understanding the fundamental concepts related to cleanliness, proper storage, and contamination prevention ensures that you are well-prepared to maintain a safe environment. The following topics are essential for gaining the necessary knowledge and skills for success.

Key Areas to Review

The following table highlights the most important safety topics that should be studied before taking the certification evaluation:

| Topic | Description |

|---|---|

| Personal Hygiene | Understanding the importance of hand washing, appropriate attire, and personal cleanliness in preventing contamination. |

| Temperature Control | Learning how to store, cook, and serve products at safe temperatures to avoid the growth of harmful bacteria. |

| Cross-Contamination Prevention | Recognizing the risks of cross-contamination and implementing methods to prevent the transfer of harmful substances. |

| Proper Storage Techniques | Understanding how to store products safely, including correct labeling, shelving, and organizing to avoid contamination. |

| Cleaning and Sanitization | Mastering the procedures for maintaining clean surfaces and utensils to prevent the spread of pathogens. |

Why These Topics Matter

Each of these topics plays a vital role in ensuring the safety and health of those who consume the products. By mastering them, you’ll be able to implement best practices in any environment, reducing risks and ensuring the well-being of your customers and colleagues. Familiarizing yourself with these key areas will help you pass the evaluation and, more importantly, contribute to maintaining high standards of safety in your workplace.

Best Resources for Test Preparation

To excel in a certification evaluation, utilizing a variety of resources can make a significant difference. The right materials will help reinforce your knowledge, highlight key areas to focus on, and provide practice opportunities to increase your confidence. From online courses to study guides and mock exams, there are many tools that can assist you in preparing effectively for the evaluation.

Top Online Platforms

There are several reliable online platforms offering comprehensive study materials, including interactive courses, videos, and quizzes. These resources often provide up-to-date information and simulate the exam format, allowing you to become familiar with the structure and types of questions you may encounter. Some recommended platforms include:

- Study.com: Offers interactive courses and practice tests to help you master the key concepts.

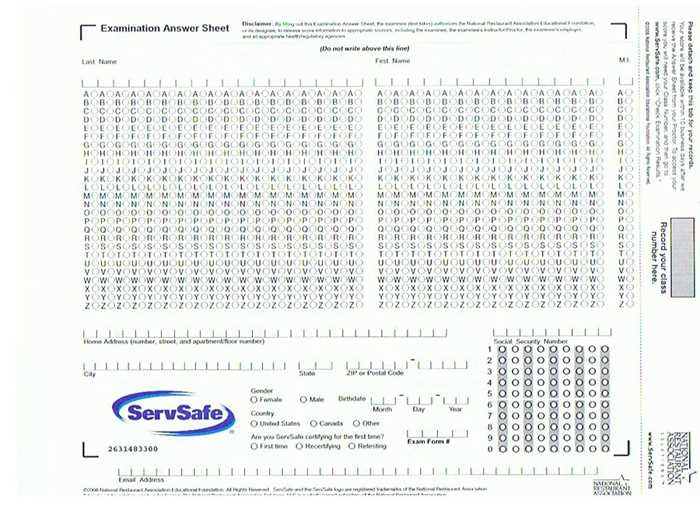

- ServSafe: A well-known resource for online training with certifications and practice exams focused on safety principles.

- FoodSafetyTraining: Provides video tutorials, study guides, and practice questions to ensure thorough preparation.

Study Guides and Books

Books and study guides can serve as excellent resources for gaining a deeper understanding of the material. Comprehensive guides typically break down complex concepts and offer tips for successful certification. Many books also come with practice questions, which can help reinforce your learning. Some popular study materials include:

- ServSafe Manager’s Guide: A well-structured book covering essential topics with practical examples and quizzes.

- National Restaurant Association Study Guide: A thorough guide that aligns with industry standards and provides in-depth explanations.

- Food Safety for Managers: A resource tailored to managers, offering insights into best practices and safety protocols.

By combining these resources with consistent practice, you can ensure a solid preparation and increase your chances of successfully passing the evaluation with confidence.

How to Handle Safety Violations

Dealing with safety violations is an essential aspect of maintaining a secure and healthy environment. When improper practices are identified, it’s crucial to act swiftly and appropriately to correct the issue, prevent harm, and ensure compliance with regulations. Addressing violations involves both immediate corrective actions and long-term preventive measures to minimize the risk of future incidents.

Steps to Address Safety Violations

When a safety violation occurs, follow these steps to resolve the issue effectively:

- Identify the Violation: Accurately assess the situation and determine the specific violation. This may involve improper handling, cross-contamination, or improper storage practices.

- Correct the Immediate Issue: Take immediate action to address the violation. This might include removing contaminated items, adjusting temperatures, or instructing employees on correct procedures.

- Notify Authorities (if necessary): In some cases, it may be necessary to inform regulatory bodies or management, especially if the violation puts health at risk or is serious in nature.

- Document the Incident: Record the details of the violation, including the nature of the issue, steps taken to resolve it, and any corrective actions implemented. This helps track patterns and ensures accountability.

- Conduct a Follow-Up: After resolving the issue, monitor the situation to ensure the corrective actions are effective and prevent recurrence.

Preventive Measures

To reduce the likelihood of violations, consider implementing these long-term strategies:

- Training Programs: Regularly educate staff on proper safety procedures and regulations to ensure everyone is aware of their responsibilities.

- Regular Inspections: Conduct frequent inspections to identify potential hazards before they result in violations. This helps maintain a proactive approach to safety.

- Clear Protocols: Establish and communicate clear protocols for handling and storing materials, as well as procedures for addressing potential risks.

- Continuous Improvement: Regularly review practices and make improvements where necessary. Keep up-to-date with safety standards and incorporate any new best practices into daily operations.

By responding quickly to violations and fostering a culture of continuous improvement, safety can be ensured, protecting both individuals and the overall operation from harm.

Certification Exam Format Explained

Understanding the format of the certification exam is crucial for effective preparation. The evaluation is designed to assess knowledge on key safety protocols, hygiene standards, and proper procedures for maintaining a healthy environment. Knowing what to expect during the exam can help reduce anxiety and increase the chances of success. Here, we break down the structure of the assessment to give you a clear idea of what will be covered and how to approach it.

General Structure

The exam typically consists of multiple sections, each testing a specific set of skills and knowledge. The following format is commonly used:

- Multiple-Choice Questions: A series of questions with several possible answers. You will need to select the most appropriate option based on your understanding of safe practices.

- True or False Statements: Statements that require you to identify whether they are correct or incorrect based on established safety guidelines.

- Scenario-Based Questions: Real-life scenarios that test your ability to apply knowledge in practical situations. These questions evaluate decision-making skills and adherence to safety protocols.

Time and Passing Criteria

The exam typically lasts between 30 to 60 minutes, depending on the provider. In most cases, a passing score is set at around 70-80%, which means answering at least 70% of the questions correctly. While the exact passing threshold can vary, it’s important to approach the exam with a focus on accuracy and knowledge application rather than just speed.

Preparation Tips

To succeed in the certification exam, consider these tips:

- Review Key Safety Practices: Make sure you are familiar with best practices for hygiene, temperature control, and risk management.

- Practice with Sample Questions: Many providers offer practice exams that simulate the real test. Taking these can help you familiarize yourself with the question format and improve your confidence.

- Study Regularly: Spreading your study time over several days is more effective than cramming. Consistent, short study sessions will help reinforce concepts.

By understanding the format and preparing effectively, you can approach the certification exam with confidence, ensuring a smoother experience and better results.

Understanding Foodborne Illnesses and Prevention

Foodborne illnesses are a serious public health concern that can affect anyone. They occur when harmful microorganisms, such as bacteria, viruses, or parasites, contaminate the items we consume. Recognizing the risks and understanding how these pathogens spread is crucial in preventing outbreaks and protecting public health. Proper handling, storage, and hygiene practices are essential to minimize the chances of contamination and ensure that meals are safe to eat.

These illnesses can lead to a variety of symptoms, ranging from mild stomach discomfort to more severe reactions, such as vomiting, diarrhea, and even long-term health complications. The spread of harmful bacteria is often facilitated by improper food handling or preparation, making it important for workers in the food industry to follow established safety protocols.

To prevent contamination, several key practices should be implemented:

- Proper Hygiene: Regular hand washing with soap and water before handling any items, especially after using the restroom or touching raw materials, is essential in minimizing contamination.

- Temperature Control: Keeping perishables at the right temperature, such as refrigerating items that require cooling and properly cooking products to safe temperatures, prevents the growth of harmful microorganisms.

- Avoid Cross-Contamination: Use separate utensils, cutting boards, and storage areas for raw and cooked items to avoid transferring harmful bacteria from one item to another.

- Regular Cleaning and Disinfection: Surfaces and equipment used in food preparation should be cleaned frequently to eliminate any lingering bacteria or viruses.

By understanding the sources of contamination and taking preventive measures, it’s possible to drastically reduce the risk of illness. The key to ensuring safety is vigilance in maintaining hygiene, proper storage, and safe handling practices at all stages of food preparation.

How Long is the Certification Valid?

The duration of validity for certification in the safety practices varies depending on local regulations and the type of establishment. Generally, most certifications remain valid for a specific number of years before requiring renewal. It is important for individuals working in environments where handling consumables is a daily task to stay updated on their certification status to maintain compliance with health and safety standards.

Factors Affecting Certification Validity

Several factors can influence the length of time a certification remains valid. These include:

- Local Legislation: Some regions may have different requirements for the length of validity based on local laws and public health standards.

- Training Updates: Periodic updates in safety protocols might necessitate re-certification or additional training to ensure adherence to the latest guidelines.

- Industry Type: Certain sectors might require more frequent renewals, depending on the nature of the products being handled and the risk factors involved.

Typical Validity Period

In general, most certifications are valid for between 2 to 5 years. After this period, individuals are typically required to either complete a refresher course or take a short assessment to renew their certification. It is advisable to check with the issuing authority for specific renewal requirements in your area.

| Region | Validity Period |

|---|---|

| United States | 2-5 years, depending on state |

| Canada | 5 years |

| United Kingdom | 3 years |

| Australia | 3-5 years |

Maintaining an active certification is essential to meet both legal and health standards. Always check the local guidelines to ensure compliance and stay informed about the renewal process.

Benefits of Earning a Certification

Obtaining a certification in proper safety practices can offer numerous advantages to individuals working in environments where consumable products are handled. This credential not only ensures compliance with local regulations but also contributes to overall workplace safety, customer confidence, and career development.

- Legal Compliance: Earning this certification helps individuals and businesses meet mandatory requirements imposed by local health authorities. It ensures that establishments adhere to hygiene and safety standards, minimizing the risk of fines or legal action.

- Improved Workplace Safety: Certified individuals are equipped with essential knowledge about handling consumable items, preventing contamination, and ensuring safe practices in all aspects of their job. This leads to fewer accidents and a healthier working environment.

- Increased Employment Opportunities: Having the proper certification can make job candidates more attractive to employers. Many businesses prefer or even require their staff to have this credential, making it a key factor in securing employment in the industry.

- Customer Trust: When customers know that a business has staff trained in proper safety procedures, it can increase their confidence and loyalty. A commitment to maintaining high hygiene standards can lead to better customer experiences and repeat business.

- Career Advancement: For those seeking career growth, holding this certification demonstrates a commitment to professional development and expertise. It can open doors to higher-level roles and leadership positions within the industry.

Overall, obtaining a certification in safe practices offers significant benefits to both individuals and businesses, fostering a safe and productive environment that meets both regulatory requirements and customer expectations.