Preparing for any comprehensive evaluation in the field of heavy lifting and load management requires a deep understanding of both the theoretical principles and hands-on skills. Whether you’re a beginner or an experienced professional, excelling in this assessment demands clarity in your knowledge of tools, techniques, and safety protocols.

Understanding essential principles is crucial for applying the right methods in various scenarios. This includes everything from calculating load weights to selecting appropriate equipment for specific tasks. The exam tests your ability to demonstrate both competence and safety in real-world situations.

To succeed, it is important to focus on practical application while also reviewing key standards that govern the industry. This guide will help you navigate the different sections of the assessment and prepare for the challenges ahead, ensuring that you are equipped with the necessary skills and knowledge.

Assessment Preparation and Key Insights

Success in this type of evaluation is built on a thorough understanding of the fundamental concepts and hands-on techniques required in load handling and securement. It is essential to not only know the theory but also to be able to apply it practically in various real-life situations. Proper preparation ensures that you can demonstrate both proficiency and safety in your field.

Core Concepts to Focus On

In order to excel, it’s important to grasp the core ideas related to weight distribution, equipment selection, and safety measures. Each question will test your ability to analyze a given situation and select the best course of action based on established standards and practices.

Key Safety and Equipment Standards

Familiarity with the tools and safety procedures is critical for achieving the best results. Ensure you are well-versed in how to handle equipment properly, recognize potential hazards, and implement safety measures during all operations.

| Topic | Importance |

|---|---|

| Load Calculations | Essential for determining the proper weight limits for each operation. |

| Equipment Selection | Critical for ensuring the right tools are used for each task. |

| Safety Protocols | Important for protecting both the operator and the surrounding environment. |

| Inspection Procedures | Key to ensuring that all equipment is in working order and safe to use. |

Overview of Load Handling Assessment

This evaluation focuses on testing the essential skills and knowledge needed for safe and effective load management. It examines your ability to handle different types of lifting tasks, use appropriate equipment, and follow safety procedures. A thorough understanding of these areas is required to ensure successful performance during the assessment.

Key topics typically include weight distribution, the proper selection of tools, and safety protocols. You will be asked to demonstrate not only theoretical knowledge but also practical application, showing that you can make informed decisions in real-life scenarios. Preparation involves familiarizing yourself with industry standards and regulations that govern these operations.

One of the critical aspects of this assessment is understanding the importance of safety in every stage of the task. The ability to recognize potential hazards and apply precautionary measures is a core part of the evaluation process. Mastery of both the theory and practical techniques is essential for achieving success.

Key Concepts to Master for Load Handling

Understanding the core principles that govern lifting and securing heavy loads is crucial for ensuring both safety and efficiency. These concepts lay the foundation for every task in the field, whether it’s selecting the right equipment, calculating weight limits, or following established safety protocols. Mastery of these key topics is essential for performing tasks confidently and competently.

Weight Distribution and Load Calculation

Accurate weight calculation is vital for selecting the proper tools and ensuring the load is safely distributed. Understanding how to calculate weight, center of gravity, and load limits helps avoid accidents and equipment failure. Mastery of this concept ensures that tasks are performed within safe operational parameters.

Equipment Selection and Usage

Choosing the correct tools for a specific job is another critical concept. It requires knowledge of various lifting devices, slings, and hardware, as well as understanding the limits of each piece of equipment. Proper selection ensures that the right strength and stability are provided for each lifting operation, reducing risks and improving efficiency.

Essential Tools for Load Handling Operations

The success of any lifting and load management task depends heavily on the correct selection and use of tools. Each piece of equipment serves a specific purpose, whether it’s securing the load, adjusting tension, or ensuring safe transport. Familiarity with these tools is essential for optimizing performance and minimizing risks during operations.

| Tool | Purpose |

|---|---|

| Hoists | Used for lifting heavy loads with minimal effort. |

| Slings | Essential for securing loads during lifting and transport. |

| Shackles | Connect various components of a lifting system securely. |

| Blocks and Pulleys | Assist in changing the direction of the load and distributing weight. |

| Load Binders | Ensure that loads remain secured during transport or lifting. |

Understanding how to select and operate these tools is key to completing each task efficiently and safely. Proper maintenance and inspection are also critical to ensure their continued effectiveness and prevent equipment failure.

Understanding Load Calculation in Load Handling

Accurate load calculation is crucial to ensure that lifting operations are performed safely and efficiently. It involves determining the total weight of the load, the center of gravity, and how to distribute the weight across lifting equipment. This knowledge helps to select the proper equipment and avoid overloading, which can lead to accidents or equipment failure.

Calculating the Total Weight

The first step in load calculation is determining the total weight of the load. This includes not only the item being lifted but also any attachments or rigging components that may be part of the load. Understanding the total weight ensures that the equipment used can handle the load safely.

Center of Gravity and Load Distribution

Another important factor is determining the center of gravity, which helps in ensuring the load remains stable during lifting. Proper load distribution prevents tipping or imbalance during the operation. Knowing how to calculate and adjust these factors is vital for maintaining safety and control throughout the process.

Common Safety Standards for Load Handling

Ensuring safety during load lifting and securing operations is essential to prevent accidents and ensure smooth project execution. Adhering to established safety protocols helps mitigate risks related to equipment failure, improper handling, and environmental hazards. These standards are designed to protect both workers and equipment from potential harm.

Safety protocols include regular equipment inspections, proper load limits, and personal protective gear. Compliance with these guidelines is crucial to avoid unsafe conditions and ensure that all operations are carried out under optimal safety measures. In addition, understanding environmental factors such as wind conditions or uneven surfaces is important for making safe decisions during each phase of the task.

For example, inspecting equipment before use is one of the most critical steps in preventing failures. Ensuring that all components, such as slings, hooks, and chains, are in good condition minimizes the risk of accidents. Additionally, verifying that the lifting capacity of each tool matches the weight of the load is fundamental to maintaining safety standards.

Preparing for Practical Load Handling Tests

Success in a hands-on assessment requires both theoretical knowledge and practical skills. The ability to execute tasks confidently and safely under real conditions is crucial. Preparation involves practicing key techniques, familiarizing yourself with the required equipment, and understanding how to assess and manage potential risks during each step of the process.

One important aspect of preparation is developing a systematic approach to each task. This includes reviewing all necessary steps, ensuring the right tools are on hand, and considering safety measures before starting any operation. Familiarity with common challenges that may arise during a practical test is also beneficial for effective problem-solving in real-time situations.

| Key Areas to Focus On | Tips for Mastery |

|---|---|

| Load Assessment | Ensure you understand how to determine weight, balance, and center of gravity. |

| Equipment Familiarity | Practice using all required tools, from slings to hoists, ensuring proper handling. |

| Safety Measures | Review safety protocols and perform mock setups to ensure your readiness. |

| Problem Solving | Simulate potential issues, such as shifting loads or equipment malfunctions, to improve response time. |

How to Interpret Load Handling Drawings

Interpreting technical drawings is essential for understanding how to safely and effectively carry out load handling operations. These drawings provide detailed information on how to arrange equipment, secure loads, and identify the necessary tools for each task. Proper interpretation of these diagrams ensures that all operations are performed according to the plan and in compliance with safety standards.

Key Elements of Load Handling Drawings

- Symbols and Markings: Recognize and understand the various symbols representing tools, equipment, and safety features.

- Load Paths: Identify the paths through which the load will move, ensuring that no obstacles are in the way and that the lifting equipment is properly positioned.

- Weight Distribution: Check the diagram for any weight distribution instructions to ensure that the load is balanced and secure.

- Dimensions: Measure the specified dimensions of the load and equipment to ensure everything fits properly and can be safely operated.

Steps for Interpreting Drawings Correctly

- Review all provided information carefully before starting any operation.

- Check the load details, including weight, size, and shape, and how they should be secured.

- Understand the placement of each piece of equipment and any special instructions for its use.

- Ensure the drawings match the actual conditions of the work site to avoid discrepancies.

By following these steps and carefully studying the drawing, you will be able to set up and execute the operation with confidence, minimizing risks and improving overall efficiency.

Types of Load Handling Equipment You Must Know

Understanding the different types of tools and equipment used in load handling is essential for ensuring both safety and efficiency. Each piece of equipment is designed for a specific task, and knowing which tool to use in a given situation can make a significant difference in the success of the operation. Familiarity with these tools helps to prevent accidents and optimize workflow during each phase of lifting and securing loads.

Common Equipment Used for Load Lifting

Hoists are typically used for lifting heavy loads. They come in various types, such as electric and manual, and are essential for moving loads vertically. Choosing the right hoist depends on the load weight and required height.

Slings are flexible straps or ropes used to secure loads. Made from materials such as steel, nylon, or polyester, slings come in different configurations, including round, flat, and endless slings, each suited for different lifting tasks. It’s important to select the correct type based on the load and lifting conditions.

Essential Hardware and Tools

Shackles are used to connect slings, hooks, or other lifting components. They ensure that the load is securely fastened during lifting. Proper selection of shackles based on load capacity and material is critical to preventing failure.

Pulleys and Blocks are used to change the direction of the load’s movement and provide mechanical advantage when lifting or moving heavy objects. These components are often used in systems to distribute weight and make lifting more manageable.

By understanding the functions and appropriate uses of these tools, operators can enhance safety and efficiency in load handling tasks.

Factors Affecting Load Distribution

Proper load distribution is critical to ensure stability, prevent accidents, and optimize the efficiency of lifting operations. Various factors influence how the weight is distributed across the lifting equipment, and understanding these variables can help operators make safer, more informed decisions. Improper distribution can lead to imbalanced loads, which can cause equipment damage or accidents during handling.

Key Factors That Impact Load Distribution

- Load Shape and Size: The shape and size of the load affect how the weight is spread across the rigging components. Irregularly shaped loads may require additional support points or specialized equipment to ensure even distribution.

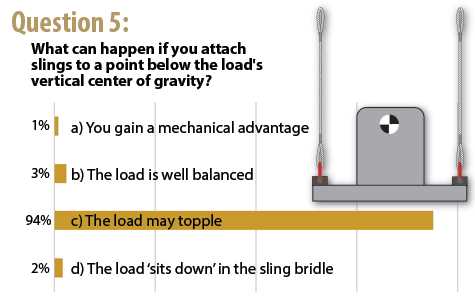

- Center of Gravity: The center of gravity determines the balance point of the load. If the center of gravity is too far from the lifting point, it may cause the load to tilt or sway during lifting.

- Weight of the Load: The total weight of the load must be evenly distributed across the lifting equipment to avoid overstressing any single component. Overloading a specific part of the rigging system can lead to equipment failure.

- Lifting Points: The number and placement of lifting points significantly affect how the load’s weight is shared among the rigging components. Proper alignment ensures that the load remains stable during the lift.

- Environmental Factors: External conditions, such as wind, temperature, and surface conditions, can impact the distribution of the load. Strong winds or uneven ground can shift the weight distribution and cause instability.

Ensuring Proper Load Distribution

- Always calculate the load’s total weight and center of gravity before beginning the lift.

- Use the appropriate rigging equipment and tools designed for the specific load and conditions.

- Ensure that lifting points are well-positioned to evenly distribute the weight.

- Monitor environmental factors, such as wind or uneven terrain, and adjust the setup accordingly.

- Perform checks throughout the lift to ensure the load remains balanced and secure.

By understanding and managing these factors, operators can ensure a safer, more effective lifting process while reducing the risk of accidents or equipment damage.

Best Practices for Slinging Loads

Properly slinging loads is essential for ensuring that heavy or awkwardly shaped objects are handled safely and efficiently. The process involves securing the load with slings in a way that evenly distributes the weight, preventing slippage or shifting during lifting. Adhering to best practices not only ensures the safety of the workers involved but also minimizes the risk of damage to the load or equipment.

Key Guidelines for Slinging Loads

- Choose the Right Sling: Select the appropriate sling material based on the load’s weight, shape, and environment. Options include chain, wire rope, and synthetic slings, each suitable for different applications.

- Inspect Slings Before Use: Always inspect slings for any signs of damage, such as cuts, frays, or kinks, that could compromise their strength. Damaged slings should be removed from service immediately.

- Ensure Proper Sling Angle: The angle at which the sling is applied plays a significant role in load stability. Avoid angles that are too steep, as they can increase the risk of the sling slipping or breaking under pressure.

- Balance the Load: Ensure that the load is evenly distributed within the sling, keeping the center of gravity centered. Improper load balance can lead to tipping or instability during the lift.

- Use Multiple Slings for Heavy Loads: For larger or heavier loads, use multiple slings to share the load’s weight. This reduces the risk of overloading a single sling and ensures a more controlled lift.

Safety Considerations When Slinging Loads

- Always ensure that slings are rated for the load’s weight and properly matched to the equipment being used.

- Use proper knots or fastening methods to secure the sling around the load, ensuring that it will not come loose during handling.

- Keep the sling free from sharp edges or abrasive surfaces that can cause wear or damage during the lifting process.

- When lifting loads, ensure that there is adequate communication between the team members to coordinate the lift effectively.

- Always follow the manufacturer’s guidelines for sling use and maintenance to ensure longevity and safety.

By adhering to these best practices, you can improve the safety and efficiency of load handling, reducing the risk of accidents and ensuring a smoother, more controlled lifting process.

Rigging Inspection Checklist

Before performing any lifting operation, a thorough inspection of all lifting equipment and components is essential to ensure safety and functionality. An inspection checklist helps identify potential issues or damage that could compromise the lift, allowing workers to address these concerns before proceeding. A regular inspection process is crucial to maintaining the integrity of the equipment and preventing accidents during operations.

Key Components to Inspect

- Slings: Check for fraying, cuts, and other signs of wear. Ensure that slings are free from knots and abrasions, which could weaken their strength.

- Hooks and Shackles: Inspect hooks and shackles for cracks, deformation, or signs of wear. Ensure that safety latches are functioning properly to prevent accidental detachment.

- Chains and Ropes: Examine chains and ropes for signs of rust, corrosion, or kinks. Any damaged or compromised components should be replaced immediately.

- Load-bearing Equipment: Ensure that load-bearing equipment such as beams, spreaders, or cranes are in good working condition and free from damage.

- Hardware and Fasteners: Verify that all bolts, nuts, and other fasteners are securely tightened and show no signs of rust or damage.

Inspection Process

- Perform a visual inspection to identify any visible signs of damage or wear on all equipment.

- Test load-bearing components for any movement or instability that could affect the lift.

- Ensure that all equipment is within its rated capacity and is appropriate for the intended load.

- Check for proper lubrication where necessary to ensure smooth operation of moving parts.

- Confirm that all safety devices, such as latches and locks, are working correctly.

A complete inspection before each lift is essential to ensure the safety of all involved in the operation. Regular checks and maintenance also help extend the lifespan of the equipment and prevent costly repairs due to neglect.

Common Mistakes in Rigging and How to Avoid Them

Even the most experienced workers can sometimes make mistakes during heavy lifting operations, which can lead to accidents or equipment failure. Understanding the most common errors and how to avoid them is crucial to ensuring both the safety of personnel and the integrity of the load. Proper training, attention to detail, and adherence to safety protocols are key to preventing these issues.

Common Mistakes and How to Prevent Them

- Improper Slinging: Using the wrong type of sling or incorrect attachment points can put excessive strain on the equipment. Always ensure that slings are rated for the weight and type of load being lifted, and use proper lifting techniques to evenly distribute the load.

- Overloading Equipment: Exceeding the load capacity of lifting gear can cause failure. Always check the rated load limits of all equipment and never exceed these limits, even when lifting seemingly lighter loads.

- Neglecting Inspections: Failing to inspect equipment before use is a common mistake that can lead to dangerous failures. Regularly inspect all gear for wear, tear, or damage and replace any faulty components before use.

- Inadequate Communication: Misunderstandings between team members during a lift can lead to mistakes. Clear communication is essential, and all workers should be aware of their roles and responsibilities before starting the operation.

- Incorrect Load Distribution: Uneven load distribution can cause instability and even equipment failure. Always ensure that the load is properly balanced, and use spreaders or other equipment to evenly distribute the weight when necessary.

Best Practices to Avoid Mistakes

- Ensure proper training for all team members and conduct regular safety drills.

- Double-check the load capacity of all lifting equipment before use.

- Perform thorough pre-lift inspections and address any issues before beginning the lift.

- Maintain open and clear communication between all workers involved in the operation.

- Ensure proper load distribution and use tools like spreader beams to assist with heavier or larger loads.

By being mindful of these common mistakes and implementing preventative measures, operators can significantly reduce the risk of accidents and ensure a safe, efficient operation. Proper preparation, training, and adherence to safety guidelines are the cornerstones of successful lifting operations.

Preparing for the Oral Part of the Exam

Successfully preparing for the oral section of an assessment involves more than just memorizing facts. It requires a deep understanding of the subject, the ability to communicate ideas clearly, and the confidence to discuss complex topics. Preparation for this part should focus on being able to explain concepts, demonstrate problem-solving skills, and answer questions with precision and clarity.

Key Strategies for Effective Preparation

- Understand Core Concepts: Ensure you have a thorough understanding of the key concepts and procedures involved in the subject matter. The oral portion often tests your ability to explain and apply this knowledge in real-world scenarios.

- Practice Clear Communication: The ability to express yourself clearly is essential. Practice speaking out loud, explaining complex topics in simple terms, and providing step-by-step explanations to demonstrate your understanding.

- Review Common Questions: While you can’t predict every question, there are common themes and topics that are frequently addressed. Reviewing past exam questions or practicing with a peer can help you anticipate and prepare for these questions.

- Simulate the Test Environment: Rehearse in a setting similar to the actual assessment. Have someone role-play as the examiner to simulate the pressure and format of the oral portion.

Tips for Success During the Oral Assessment

- Listen carefully to each question before answering. Take a moment to collect your thoughts if necessary.

- Provide clear, concise, and well-structured answers. Avoid rambling or over-explaining.

- Be prepared to give examples or explain procedures to back up your answers.

- Stay calm and confident. Even if you don’t know an answer immediately, maintain a positive and professional attitude.

With focused preparation and effective communication skills, you can approach the oral section of the assessment with confidence. Take the time to understand the material, practice your speaking skills, and anticipate common questions to increase your chances of success.

What to Expect During the Rigging Exam

During the assessment, you will be tested on both theoretical knowledge and practical skills, ensuring that you understand the core concepts and can apply them in real-life scenarios. The assessment will likely consist of a mix of multiple-choice questions, hands-on tasks, and oral evaluations designed to gauge your understanding and your ability to perform under pressure.

Expect to be asked to demonstrate your ability to handle various equipment, interpret technical drawings, and solve problems related to load management and safety protocols. There may also be situations where you need to explain the steps of a procedure or justify your decisions regarding the selection of tools and techniques. The goal is to assess how well you can apply your knowledge in practical situations.

In addition to testing your technical skills, the assessment may also include questions that evaluate your understanding of safety standards, industry regulations, and best practices for ensuring smooth and safe operations. It is important to be prepared for both theoretical questions and hands-on tasks, as each aspect is critical to your overall performance in the assessment.

Study Resources for Rigging Final Exam

To ensure you’re fully prepared for the assessment, it’s essential to use a variety of study materials that cover both theoretical knowledge and practical skills. Access to quality resources will help you grasp key concepts, understand safety protocols, and familiarize yourself with the tools and techniques you’ll be evaluated on.

Recommended Resources

- Textbooks and Manuals: Study the industry-specific textbooks and technical manuals that outline best practices, load management techniques, and safety standards. These are often the foundation of exam content.

- Online Courses: Enroll in specialized online courses or webinars that offer comprehensive lessons and practice quizzes to test your knowledge.

- Industry Regulations: Familiarize yourself with local and international safety standards, as understanding these regulations is crucial for your success.

- Instructional Videos: Watch videos that demonstrate common procedures and practical applications, as visual learning can enhance your understanding.

Additional Preparation Tips

- Practice Tests: Take practice exams to familiarize yourself with the format and timing of the assessment.

- Peer Study Groups: Join study groups or forums to discuss complex topics and share insights with others preparing for the same assessment.

- Hands-on Experience: If possible, gain real-world experience by participating in practice scenarios to develop muscle memory for certain tasks.

By combining these resources and strategies, you’ll be able to enhance both your theoretical understanding and practical expertise, ultimately boosting your confidence during the assessment.