For individuals pursuing careers in climate control and cooling systems, mastering the core concepts is essential. A strong understanding of system components, operation methods, and troubleshooting techniques is critical for success in professional settings. This section covers key topics and practices that will help you prepare for upcoming evaluations in this technical field.

By focusing on various aspects of system design, maintenance, and diagnostics, you can hone your knowledge to confidently handle both theoretical and practical challenges. Expertise in the underlying principles and hands-on experience with equipment will serve as a solid foundation for anyone looking to excel in their assessments.

Preparation is the key to demonstrating competence, and having the right approach will not only help you answer technical queries but also enhance your ability to troubleshoot and maintain complex units effectively.

Refrigeration Exam Questions and Answers

When preparing for technical assessments in the field of cooling systems, understanding the core concepts is crucial. The ability to recall information quickly and apply it to practical situations is what differentiates a skilled professional from a novice. This section provides a comprehensive look at the essential topics that are often tested in such evaluations, helping candidates familiarize themselves with common scenarios and troubleshooting techniques.

Key Topics Covered in Technical Assessments

Test-takers can expect a broad range of subjects, from basic principles to advanced system operations. Focus is placed on identifying components, understanding cycles, and maintaining safe working practices. Being able to demonstrate a strong grasp of these concepts is critical for anyone aiming to pass with confidence. Key areas typically include equipment specifications, troubleshooting steps, and industry regulations.

Preparation Tips for Success

Success in technical evaluations relies heavily on focused preparation. Candidates should prioritize hands-on experience with equipment, reviewing relevant theoretical materials, and practicing problem-solving exercises. Familiarity with typical setup configurations, diagnostic methods, and standard operational procedures ensures readiness for even the most challenging questions that may arise.

Essential Refrigeration Principles to Know

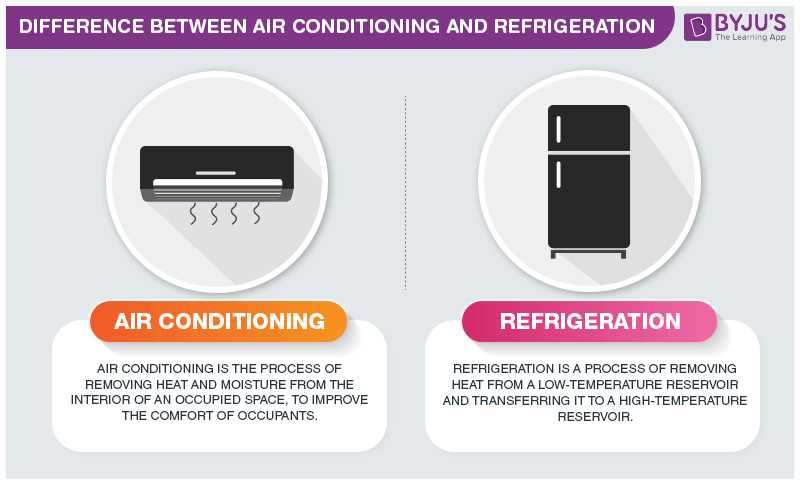

Mastering the fundamental concepts behind cooling systems is crucial for anyone working with temperature control technologies. Understanding how heat transfer, pressure, and volume interact in a closed-loop system is key to ensuring optimal performance and efficiency. These core principles lay the foundation for troubleshooting, maintaining, and operating equipment effectively.

Thermodynamic principles are central to system operation. Whether it’s managing heat flow or controlling the pressure within pipes, these concepts govern how energy moves through the system. Knowledge of how temperature gradients affect material properties and the efficiency of cooling processes is essential for achieving the desired outcomes in various applications.

Fluid dynamics is another critical area to understand. Fluids in these systems undergo phase changes that play a significant role in transferring heat. Recognizing the impact of different refrigerants and their behavior in the system helps optimize performance and ensure safe operation.

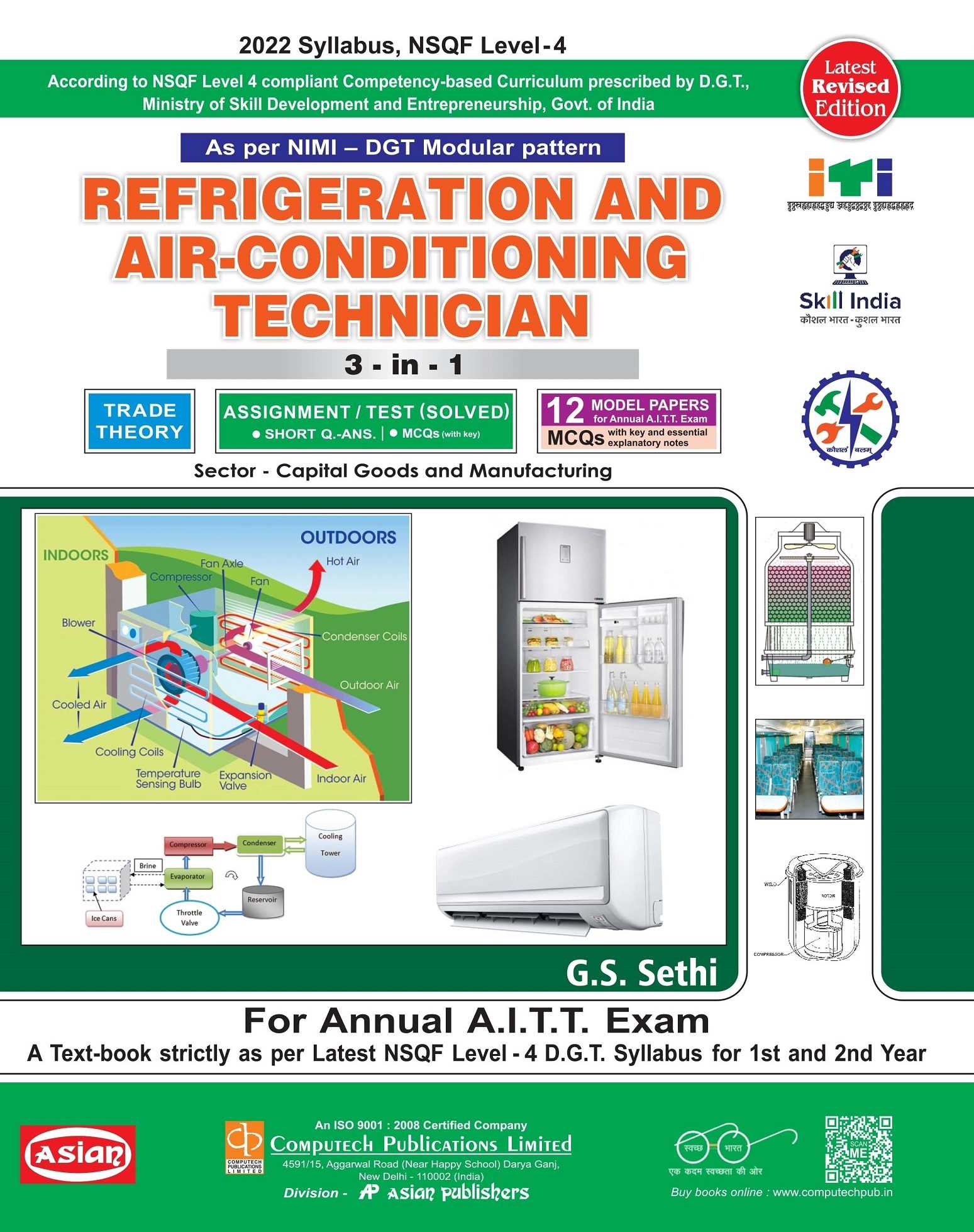

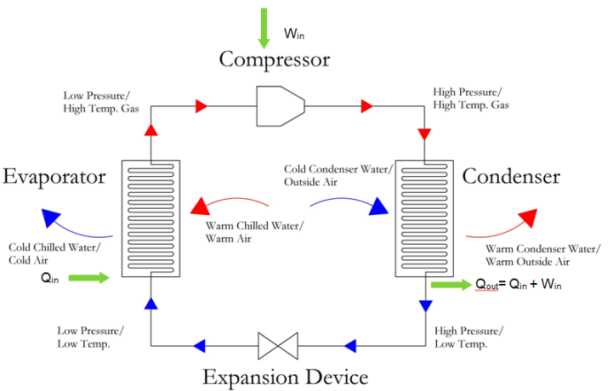

Key Components in Refrigeration Systems

Understanding the primary elements that make up cooling systems is essential for anyone working with temperature control technology. These systems rely on a series of interrelated parts that work together to maintain consistent temperatures, optimize efficiency, and ensure safe operation. Familiarity with each component is vital for both installation and troubleshooting tasks.

Compressor is one of the most important components, responsible for pressurizing the refrigerant and initiating the circulation process. It draws in low-pressure gas and compresses it, turning it into a high-pressure, high-temperature gas. This step is crucial for driving the cycle forward and enabling heat exchange to occur.

Evaporator coils are another key part, where heat is absorbed from the environment. As the refrigerant evaporates in the coils, it absorbs heat, lowering the temperature in the space being cooled. The heat is then carried away by the refrigerant, which flows toward the condenser for heat release.

Condenser plays a critical role in expelling the absorbed heat to the surrounding environment. As the high-pressure gas passes through the condenser coils, it cools down and condenses into a liquid form, ready to be recycled back into the evaporator. The efficiency of this heat transfer process is vital for the overall effectiveness of the system.

Expansion valve regulates the flow of the refrigerant into the evaporator. It controls the pressure drop, allowing the refrigerant to expand and cool before entering the evaporator coils, where it will absorb heat once again. Proper functioning of this valve ensures that the refrigerant is at the correct pressure and temperature for efficient cooling.

Understanding Refrigerant Types and Uses

In temperature control systems, the substance responsible for transferring heat plays a critical role in system performance. Different types of cooling agents are chosen based on their properties, efficiency, and environmental impact. Knowing the characteristics of each option is essential for ensuring optimal system operation and adhering to industry regulations.

Commonly Used Coolants

The selection of a specific fluid depends on various factors, such as the desired temperature range, system design, and environmental considerations. Some fluids are more efficient at heat absorption, while others are chosen for their lower environmental footprint or better safety profiles. Here are a few of the most commonly used coolants:

| Coolant Type | Properties | Common Uses |

|---|---|---|

| R-134a | Low toxicity, moderate environmental impact | Automotive air conditioning, commercial cooling systems |

| R-22 | Efficient, high global warming potential (GWP) | Older HVAC systems (phasing out due to environmental concerns) |

| R-410A | Higher efficiency, ozone-friendly | Modern air conditioning units, heat pumps |

| Ammonia (NH3) | Highly efficient, toxic, flammable | Industrial refrigeration, large-scale cooling applications |

Environmental Considerations

Environmental impact is an increasingly important factor in selecting a coolant. Many traditional substances have been phased out due to their high global warming potential or ozone-depleting effects. Modern systems are moving toward more sustainable options that provide similar performance while minimizing harm to the atmosphere. It is essential for professionals to stay informed about evolving regulations and the availability of greener alternatives.

Common Refrigeration Cycle Questions

In the process of managing temperature control systems, understanding the cycle through which energy is transferred is essential. The mechanics behind how heat is absorbed, moved, and expelled are central to system functionality. Below, we explore some of the most frequently discussed concepts related to this essential loop.

Key Stages of the Cycle

The fundamental stages of the cooling process involve a series of transitions that the working fluid undergoes. These transitions include compression, condensation, expansion, and evaporation. Each stage plays a distinct role in ensuring the efficient movement of heat from one area to another. Mastery of these stages is necessary for understanding system behavior and performance.

Why Is Heat Transfer Critical?

Understanding the importance of heat transfer in the cycle is vital for troubleshooting and optimizing system efficiency. The heat absorbed by the fluid in the evaporator must be effectively carried through the system and released through the condenser. Variations in temperature and pressure at different points in the system directly influence the overall efficiency of the operation.

Safety Practices for Refrigeration Technicians

Working with cooling systems requires a strong commitment to safety, as the nature of the tasks involves handling pressurized fluids, electrical components, and hazardous materials. Technicians must be aware of potential risks and follow strict protocols to minimize the chance of accidents and ensure safe operations. A thorough understanding of safety measures is essential for both personal well-being and the successful completion of tasks.

Technicians should always wear appropriate protective gear, such as gloves, safety glasses, and work boots, to prevent injuries. Additionally, ensuring that all equipment is properly maintained and inspected before use is critical in avoiding malfunctions that could lead to hazardous situations. Knowing how to handle emergency situations, such as refrigerant leaks or electrical failures, is also vital for ensuring safety in the workplace.

Energy Efficiency in Refrigeration Systems

Maximizing energy efficiency in cooling systems is not only essential for reducing operational costs but also for minimizing environmental impact. An efficient system consumes less power, operates more reliably, and helps meet sustainability goals. Understanding the factors that contribute to system efficiency can guide technicians in making improvements and optimizing performance.

There are several strategies for improving energy efficiency in cooling systems, including:

- Proper system sizing: Ensuring that the system is appropriately sized for the space or load it serves can prevent energy waste caused by overwork or underperformance.

- Regular maintenance: Routine checks and servicing, such as cleaning coils and replacing filters, help maintain optimal operation and reduce energy consumption.

- Upgrading components: Replacing older, less efficient components like compressors or fans with more energy-efficient models can significantly reduce energy use.

- Improving insulation: Proper insulation around pipes and ducts minimizes heat loss, helping the system maintain the desired temperature with less energy.

- Optimizing cycle control: Fine-tuning temperature settings and cycle timing can help reduce the number of start/stop cycles, conserving power.

By addressing these key areas, technicians can ensure that cooling systems operate at peak efficiency, saving both energy and costs over the long term.

Diagnostic Techniques for Refrigeration Units

Identifying issues within cooling systems requires a systematic approach and a good understanding of how each component functions. Technicians rely on a combination of observation, measurement, and testing to pinpoint problems, whether it’s a lack of cooling, system inefficiency, or component failure. Effective diagnostics ensure that repairs are accurate and timely, preventing unnecessary downtime and ensuring the system runs smoothly.

Visual Inspection and Common Signs

The first step in diagnosing issues is often a thorough visual inspection. Look for obvious signs of malfunction, such as leaks, ice build-up, or unusual noises. External damage to pipes, hoses, or insulation can also provide important clues. Observing these signs can help narrow down the potential problems, allowing technicians to focus their testing on specific components.

Using Diagnostic Tools

Modern diagnostic tools allow technicians to measure critical parameters such as pressure, temperature, and electrical current. Pressure gauges can indicate whether the system is operating within the correct pressure range, while temperature sensors help identify if the evaporator and condenser coils are functioning as expected. Electrical testing tools, such as multimeters, can help verify the performance of motors, compressors, and thermostats.

By combining visual inspections with these advanced tools, technicians can accurately diagnose issues, leading to faster repairs and improved system reliability.

Important Codes and Regulations to Follow

Ensuring that cooling systems are installed, maintained, and repaired according to established standards is essential for both safety and performance. Compliance with industry regulations helps prevent accidents, promotes environmental protection, and ensures systems operate efficiently. Technicians must be familiar with the relevant codes that govern the handling of cooling agents, electrical connections, and overall system operation.

Key Safety Standards

Safety is paramount when working with cooling systems. Technicians must adhere to local, national, and international codes to reduce the risks associated with electrical hazards, high-pressure systems, and harmful substances. Some of the most important standards include:

- OSHA (Occupational Safety and Health Administration): Ensures worker safety and sets guidelines for handling hazardous materials.

- EPA (Environmental Protection Agency): Regulates the use of cooling agents to prevent damage to the ozone layer and minimize global warming potential.

- NFPA (National Fire Protection Association): Sets standards for safe installation and maintenance of fire prevention equipment in cooling systems.

Building and Installation Codes

Along with safety, adherence to building codes is essential during installation. These regulations ensure that systems are installed in a manner that is both efficient and safe for the building’s occupants. Key codes to consider include:

- International Mechanical Code (IMC): Governs the installation of mechanical systems, including temperature control units.

- International Code Council (ICC): Provides guidelines for system design, energy efficiency, and safety measures.

- Local Building Codes: Often specific to regions, these codes ensure systems meet local energy, safety, and environmental standards.

By staying updated with these important codes and regulations, technicians can help ensure that systems are not only safe but also environmentally friendly and energy efficient.

Basic Thermodynamics in Refrigeration

Understanding the fundamental principles of energy transfer is crucial for effectively managing temperature control systems. Thermodynamics plays a key role in determining how heat is absorbed, transferred, and released during the cooling process. Grasping these concepts is essential for both troubleshooting and optimizing system performance.

At the core of these systems, energy transformations occur as heat is moved from one area to another. This process involves key thermodynamic principles such as energy conservation, pressure, temperature, and phase changes. These principles are essential for understanding how to design and maintain systems that efficiently regulate temperature.

Key Thermodynamic Concepts

Several thermodynamic concepts are central to the operation of cooling systems:

- Heat Transfer: The movement of heat from a warmer area to a cooler area is fundamental. It occurs through conduction, convection, and radiation, with each method playing a different role in the cycle.

- Phase Changes: The transition of the working fluid between liquid and gas states is crucial. These phase changes enable the system to absorb and release heat effectively.

- Pressure and Temperature Relationship: The behavior of gases under varying pressure and temperature conditions is key to understanding how systems function efficiently.

The Role of Work and Energy

The process of moving heat from one space to another requires energy input, typically in the form of mechanical work. This work is performed by compressors, fans, and pumps, which help to circulate the working fluid through the system. The amount of work required depends on the pressure and temperature conditions of the system, as well as the efficiency of the components used.

By understanding these basic thermodynamic principles, technicians can improve system design, enhance efficiency, and troubleshoot effectively when issues arise.

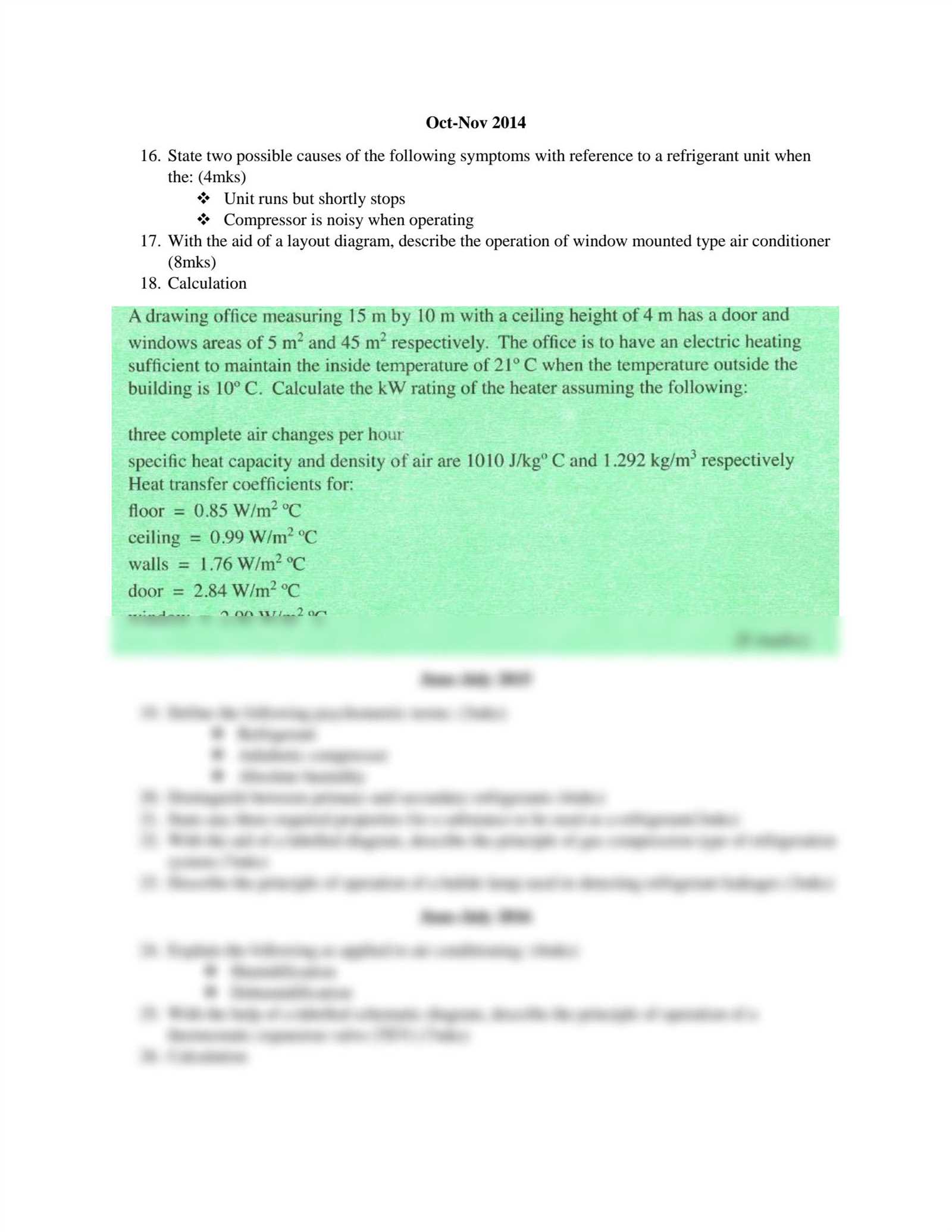

Common Troubleshooting Scenarios in Refrigeration

When issues arise in cooling systems, identifying the root cause is essential for prompt and effective repairs. Common problems often manifest as poor performance, unusual noises, or system failures. Technicians rely on systematic diagnostic procedures to evaluate various components and pinpoint the specific issue. Understanding the most frequent scenarios helps technicians address problems more efficiently and minimize downtime.

Frequent Issues and Their Causes

There are several typical problems that technicians encounter during maintenance or repair. Understanding the possible causes for each issue can help speed up the troubleshooting process.

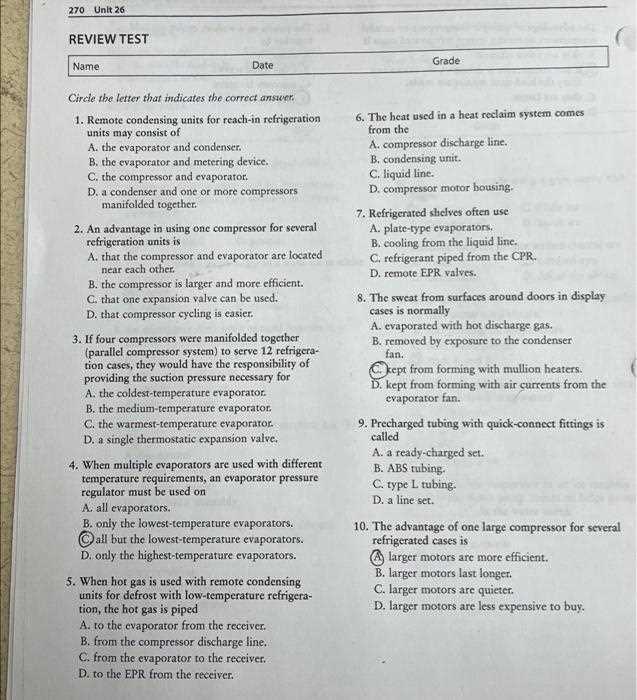

| Issue | Possible Cause | Solution |

|---|---|---|

| System Not Cooling | Low refrigerant levels, compressor malfunction, dirty coils | Check for leaks, test the compressor, clean the coils |

| Unusual Noises | Faulty fan, compressor issues, loose parts | Inspect and replace damaged components, tighten loose parts |

| Ice Buildup | Blocked airflow, low refrigerant, dirty evaporator coils | Clear airflow, check refrigerant levels, clean coils |

| Inconsistent Temperature | Faulty thermostat, improper refrigerant charge, blocked air filter | Calibrate thermostat, add refrigerant, replace or clean air filter |

Step-by-Step Troubleshooting Process

When confronted with any issue, following a structured troubleshooting process can help efficiently identify the problem. The general steps include:

- Initial Observation: Listen for unusual sounds, check for visible leaks or damage, and take note of the system’s behavior.

- Testing Components: Use gauges to check pressure, verify temperatures, and test electrical components.

- Inspection and Replacement: Clean, replace, or repair any parts that are found to be faulty or worn out.

- Final Check: After repairs, ensure that the system is operating within its required parameters and performing optimally.

By systematically addressing these common issues, technicians can ensure that systems remain efficient and functional, minimizing disruptions and preventing future breakdowns.

Maintenance Tips for Long-Lasting Systems

Proper maintenance is essential for ensuring the longevity and efficiency of cooling units. Regular care not only helps prevent unexpected breakdowns but also enhances performance and reduces operational costs. By following a few essential maintenance practices, technicians can ensure that systems continue to operate optimally for years.

Essential Maintenance Practices

Here are several key practices that can help extend the life of any cooling system:

- Regular Cleaning: Keep the evaporator and condenser coils free from dirt and debris. Dirty coils reduce system efficiency and can cause overheating.

- Monitor Refrigerant Levels: Low refrigerant levels can indicate leaks and result in poor system performance. Check the refrigerant regularly and refill as necessary.

- Inspect Fans and Compressors: Ensure that fans and compressors are working correctly. These components play a crucial role in maintaining the proper airflow and pressure within the system.

- Check for Leaks: Regularly inspect for refrigerant leaks or water condensation issues. Leaks can severely damage components and reduce overall efficiency.

- Test Electrical Components: Inspect wiring and connections for any signs of wear or damage. Faulty electrical components can lead to system failures and safety hazards.

Proactive Monitoring and Preventive Measures

In addition to the basic maintenance tasks, it is important to implement a proactive monitoring strategy to ensure the system remains in peak condition:

- Scheduled Inspections: Set up regular inspections based on the manufacturer’s recommendations or the system’s usage to catch issues before they become serious problems.

- Keep Systems Level: Ensure that all parts of the system, including the compressor, are level to prevent stress on components and enhance their lifespan.

- Upgrade When Needed: Consider upgrading older components with newer, more energy-efficient models as they become available to improve performance and reliability.

By following these maintenance tips, technicians can help ensure that cooling systems are running smoothly, efficiently, and without issues for a longer period of time. Proper care is the key to maximizing system reliability and minimizing costly repairs.

Test Preparation for Refrigeration Exams

Effective preparation is the key to success when it comes to mastering the technical knowledge required for certification assessments in the cooling industry. Whether you are preparing for a certification or a professional assessment, understanding core concepts and practicing problem-solving skills will help you gain the confidence needed to excel. This section outlines some strategies and tips that can guide you through the preparation process.

Key Areas to Focus On

When studying for a certification, focus on the fundamental concepts that are commonly tested. The following areas are essential to cover:

- Basic Principles: Understand the core concepts, such as heat transfer, pressure-temperature relationships, and the principles of fluid dynamics in cooling systems.

- Component Identification: Be familiar with the various parts of a cooling system, their functions, and how they interact with each other to maintain system efficiency.

- System Troubleshooting: Practice diagnosing issues based on symptoms and the use of tools to resolve common faults effectively.

- Industry Regulations: Familiarize yourself with the safety standards, environmental regulations, and industry codes that govern the use and handling of cooling systems.

Effective Study Techniques

In addition to focusing on the key areas, applying the right study techniques can significantly improve your preparation. Consider the following strategies:

- Practice with Mock Tests: Take advantage of practice exams to simulate the test environment and gauge your understanding of the material.

- Create Study Guides: Summarize key concepts and create study sheets to highlight important formulas, principles, and terms.

- Join Study Groups: Collaborate with peers to share insights and discuss challenging topics. Group study can help reinforce your understanding.

- Hands-On Experience: Whenever possible, gain hands-on experience by working with cooling systems to apply theoretical knowledge in real-world settings.

By following these preparation strategies, you can improve your readiness for any assessment and increase your chances of success in the technical certification process. Dedicate time to practice and review, and stay focused on mastering the essential concepts.

Advanced Refrigeration System Questions

In this section, we will delve into more complex aspects of cooling technology, focusing on advanced principles and systems. These concepts are essential for professionals who are looking to deepen their knowledge and tackle more intricate issues within the field. Understanding the advanced topics can help troubleshoot complex systems and improve operational efficiency.

Critical Areas to Explore

To master advanced systems, you need to grasp several key concepts and technical details that go beyond basic principles. The following areas are essential for understanding complex cooling units:

- Heat Exchange Efficiency: Focus on optimizing heat transfer processes. Understanding the thermodynamics of heat exchange can help improve energy efficiency in large systems.

- Energy Consumption Reduction: Learn how to calculate and reduce energy consumption in high-demand systems, ensuring that the system operates with minimal energy waste.

- System Integration: Study how different components in a large cooling unit work together, from compressors to expansion valves, ensuring they are all synchronized for peak performance.

- Alternative Refrigerants: Investigate the use of environmentally friendly refrigerants, including their impact on system performance and efficiency in comparison to traditional refrigerants.

Key Problem-Solving Techniques

Advanced systems often present unique challenges that require a deep understanding of complex variables. The following techniques are crucial for diagnosing and resolving intricate issues:

- Pressure-Temperature Relationship: Analyze the system’s performance by studying pressure-temperature charts and understanding the implications for cooling efficiency.

- Leak Detection: Learn advanced methods for identifying and repairing refrigerant leaks, as this is critical for maintaining system integrity and preventing performance degradation.

- Control System Troubleshooting: Develop skills in diagnosing electronic control systems and sensors, which are increasingly common in modern cooling systems.

- System Optimization: Focus on techniques for fine-tuning system parameters, such as flow rates and compressor speed, to enhance overall system performance.

Mastering these advanced topics will not only enhance your technical abilities but will also give you the skills needed to tackle high-level challenges and ensure that cooling systems perform optimally under all conditions.

Understanding Heat Transfer in Refrigeration

Effective cooling relies heavily on the principles of heat transfer. Understanding how heat moves through various mediums is crucial for ensuring that cooling systems perform efficiently. By controlling how heat is absorbed, transported, and released, systems can be optimized for maximum performance and minimal energy consumption. This section covers the fundamental concepts of heat movement within cooling units and how they influence system design and function.

Heat transfer in cooling systems typically occurs through three primary mechanisms: conduction, convection, and radiation. Each method plays a significant role in how temperature control is achieved, and understanding these processes is essential for anyone working with complex cooling technologies.

Heat Transfer Mechanisms

To understand heat transfer, it’s important to grasp the following concepts:

- Conduction: The process by which heat is transferred through a solid material. This occurs when heat flows from the warmer part of the system to the cooler part, such as in heat exchangers or evaporators.

- Convection: The transfer of heat through fluids (liquids or gases). In cooling systems, convection is essential for moving heat away from the source and into the surrounding environment. This process is often seen in the operation of cooling coils or air circulation systems.

- Radiation: Heat transfer through electromagnetic waves, typically from a warmer surface to a cooler one. While less common in cooling systems, it can still influence heat loss or gain in some applications.

Factors Affecting Heat Transfer Efficiency

Several factors can impact the efficiency of heat transfer in a system. These factors must be optimized to achieve effective cooling:

| Factor | Impact on Heat Transfer |

|---|---|

| Temperature Difference | The greater the difference in temperature between two substances, the more efficient the heat transfer will be. |

| Material Properties | Materials with high thermal conductivity, such as metals, facilitate better heat transfer, while insulating materials slow it down. |

| Surface Area | Larger surface areas increase the amount of heat that can be exchanged between surfaces. |

| Fluid Flow Rate | The rate at which the fluid moves can significantly affect the efficiency of heat transfer, as faster flow rates often result in better heat removal. |

By understanding these fundamental mechanisms and factors, professionals can better design, troubleshoot, and optimize cooling systems to achieve maximum efficiency. Proper management of heat transfer ensures that the systems remain effective and energy-efficient, leading to longer-lasting equipment and reduced operational costs.

Electrical Systems in Refrigeration Units

Electrical components play a vital role in the operation of cooling systems, providing the necessary power and control for various elements. From compressors to fans, the electrical systems ensure that these units operate efficiently and effectively. Proper understanding of how electrical circuits are integrated into cooling technology is essential for maintenance, troubleshooting, and optimizing system performance.

Key Electrical Components

Several crucial electrical components are involved in the operation of cooling systems:

- Compressor Motors: These motors are responsible for driving the compressor, which is central to the cooling cycle. Proper functioning of the motor is critical for the unit’s efficiency.

- Thermostats: Used to regulate the temperature within the system, thermostats control when the unit turns on or off, ensuring the desired environmental conditions are maintained.

- Capacitors: These components provide the necessary start-up power to electric motors, ensuring smooth operation, especially during system startup.

- Relays and Contactors: These components act as switches to control the flow of electrical current, allowing the system to respond to different operational conditions.

- Fuses and Circuit Breakers: Safety devices that protect the system by interrupting the flow of electricity in case of overload or short circuit, preventing damage to components.

Electrical Troubleshooting Tips

When diagnosing electrical issues in cooling units, it’s essential to focus on common problem areas:

- Power Supply: Ensure that the unit is receiving the correct voltage and current. Check for any issues in the main power circuit that could disrupt the system.

- Motor Function: If the compressor or fan motor isn’t working properly, it could indicate issues with the motor windings or connections. Checking for signs of wear and tear can prevent more significant problems.

- Control System: Faulty thermostats or control circuits can lead to improper functioning of the system. It’s important to test these components regularly for accuracy and reliability.

- Overcurrent Protection: Check for blown fuses or tripped breakers, as these can prevent the system from starting or operating properly.

Having a clear understanding of these electrical components and troubleshooting methods ensures that the system remains operational and avoids costly downtime. Regular maintenance, testing, and component checks are key to keeping electrical systems running smoothly in any cooling unit.

Future Trends in Refrigeration Technology

The world of cooling systems is continuously evolving, driven by advancements in technology, environmental concerns, and energy efficiency. Innovations in design, materials, and control systems are shaping the future of temperature regulation across various industries. As demand for more sustainable and efficient solutions grows, several key trends are emerging in the field of cooling technology.

Advancements in Efficiency and Sustainability

One of the most significant trends in cooling technology is the push for greater efficiency and environmental sustainability. With stricter regulations around energy consumption and the impact of coolants on the environment, the industry is adapting to meet new standards.

- Eco-friendly Coolants: The shift towards using natural and non-toxic refrigerants, such as CO2, ammonia, and hydrocarbons, is increasing. These alternatives are less harmful to the ozone layer and have lower global warming potential compared to traditional refrigerants.

- Energy-efficient Components: New compressor technologies, energy-saving fans, and high-performance heat exchangers are making systems more efficient, reducing electricity consumption and operating costs.

- Smart Controls: The integration of Internet of Things (IoT) technology enables better monitoring and control of cooling systems. Smart thermostats, sensors, and predictive maintenance software help optimize energy use and extend system lifespans.

Automation and Artificial Intelligence

Automation and AI are becoming increasingly influential in the design and operation of cooling systems. These technologies are making systems more adaptive and self-sufficient, improving both performance and reliability.

- AI-driven Diagnostics: Artificial intelligence algorithms can predict potential system failures, provide real-time diagnostics, and suggest corrective actions before issues escalate, reducing downtime and repair costs.

- Automation in Monitoring: Advanced sensors and automated control systems can continuously monitor temperature, humidity, and energy use, adjusting operations automatically to optimize conditions without manual intervention.

- Robotic Maintenance: Robotics and drones are being explored for use in performing routine inspections and maintenance tasks, reducing the need for human intervention in potentially hazardous environments.

As technology continues to advance, the future of cooling systems will focus on improving performance, reducing energy consumption, and minimizing environmental impact. With ongoing research and development, the industry is set to meet the challenges of tomorrow while enhancing the overall user experience.